Description

Basic Parameters

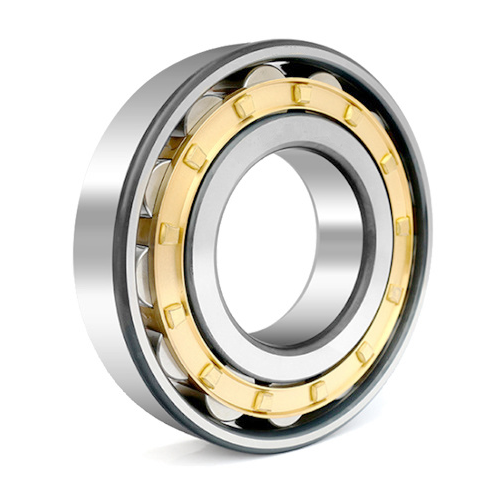

The cylindrical roller bearing NF406 is engineered with essential parameters to deliver robust radial load support in various mechanical setups. It features a bore diameter of 30 mm, an outer diameter of 72 mm, and a width of 19 mm, making it suitable for medium-to-large industrial applications. The bearing incorporates a single row of cylindrical rollers within its raceways, designed to handle high radial loads efficiently while allowing limited axial displacement, which is ideal for systems where slight shaft movement may occur due to thermal expansion or operational forces. With a dynamic load rating (C) of approximately 48.5 kN and a static load rating (C₀) of around 47 kN, it can withstand both continuous operational loads and occasional shock loads effectively. Under well-lubricated conditions, the bearing operates at a recommended maximum rotational speed of 8,000 RPM, balancing performance and durability. Weighing approximately 0.3 kg, it combines a sturdy design with manageable weight, making it suitable for applications such as gearboxes, pumps, conveyors, and heavy-duty machinery where reliable radial load capacity and moderate speed are required.

Product Application

1. Industrial Machinery & Heavy Equipment

Gearboxes & Transmissions:

In industrial gear reducers, winder drives, and mining machinery gearboxes, the NF406 efficiently supports high radial loads from gear meshing and torque transmission. Its single-row cylindrical roller design maximizes contact area with raceways, delivering a dynamic load rating (C) of 48.5 kN and static load rating (C₀) of 47 kN—suitable for intermittent heavy-duty operations, such as in steel mills, cement plants, or construction equipment.

Pumps & Compressors:

Used in centrifugal pumps for water supply systems, hydraulic pumps in press machines, or air compressors in industrial plants, the bearing stabilizes rotating shafts under radial forces from fluid pressure and mechanical vibrations. Its tolerance for limited axial displacement (due to non-locating design) accommodates thermal expansion in high-temperature environments, such as oil refineries or power generation facilities.

Conveyor & Material Handling Systems:

In belt conveyors for bulk material transport (e.g., coal, grain, or ores), the NF406 enables low-friction rotation of drive pulleys and idler rollers. Its 8,000 RPM speed rating and 0.3 kg weight ensure consistent performance in high-load, high-cycle applications, reducing energy consumption while withstanding shock loads from material impact during loading/unloading.

2. Energy & Power Systems

Wind Turbine Subsystems:

For small-to-medium wind turbines or generator auxiliary drives, the bearing supports low-speed shafts and gearbox intermediate stages, transferring radial loads from blade aerodynamics to the main structure. Its resistance to occasional torsional vibrations and misalignments (common in wind environments) enhances system reliability and reduces maintenance costs.

Electric Motors & Generators:

In industrial electric motors (e.g., 50-100 kW ratings) for pumps, fans, or machine tools, the NF406 maintains shaft alignment under radial magnetic forces and rotor weight. Its compatibility with standard lubrication (grease or oil) ensures stable operation in temperature ranges from -20°C to 120°C, critical for continuous-duty power transmission.

3. Transportation & Automotive Applications

Commercial Vehicle Systems:

On trailers, agricultural machinery (e.g., combines, tractors), or construction vehicles, the NF406 supports wheel hubs and axle components under heavy radial loads from vehicle weight and uneven terrain. Its robust design minimizes wear in dusty or wet environments when paired with sealed configurations, extending service life in harsh operating conditions.

Railway Subsystems:

Used in auxiliary railway equipment such as brake systems, door drives, or air conditioning compressors, the bearing delivers reliable performance in vibration-prone environments. Its ability to handle moderate axial movements (e.g., during track transitions) without compromising stability makes it suitable for secondary rotational components.

4. Key Application Advantages

Exceptional Radial Load Capacity:

The single-row roller design outperforms ball bearings in heavy radial load scenarios, making it ideal for machinery subjected to continuous or intermittent high loads (e.g., gearboxes, presses).

Axial Displacement Tolerance:

Non-locating design allows limited axial movement (up to ±0.5 mm under normal loads), accommodating shaft elongation due to thermal expansion or operational forces without causing excessive stress on raceways.

Durability & Cost Efficiency:

Balancing a 47 kN static load rating with a 0.3 kg weight, the bearing offers a cost-effective solution for mid-to-high-load applications, reducing downtime through reliable performance and extended lubrication intervals.

Versatile Installation:

Standard dimensions (30x72x19 mm) align with industry norms, enabling easy replacement in existing equipment or integration into new designs without custom modifications.

5. Operational Guidelines & Maintenance Tips

Lubrication Strategy:

Use lithium-based grease for general applications (re-lubricate every 1,000 hours or as per manufacturer guidelines).

For high-temperature environments (above 100°C), switch to synthetic oil lubrication to maintain viscosity and reduce friction, ensuring the 8,000 RPM speed rating is sustained.

Environmental Protection:

In dusty, humid, or corrosive environments, specify bearings with pre-installed rubber seals (RZ type) or metal shields (ZZ type) to prevent contamination and lubricant leakage.

Regularly inspect seals for damage and clean external surfaces to avoid abrasive particle ingress.

Installation Best Practices:

Ensure precise shaft and housing alignment (max misalignment angle: 0.5°) to prevent edge loading on rollers.

Use hydraulic presses or bearing installers for press-fit applications to avoid impact damage; for clearance fits, secure with locking nuts or snap rings to prevent axial movement.

Product List

| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight (kg) | |||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | ||

| NF406 | 12406 | 30 | 90 | 23 | 62800 | 55000 | 0.75 | |

| NF407 | 12407 | 35 | 100 | 25 | 75200 | 68900 | 1.1 | |

| NF408 | 12408 | 40 | 110 | 27 | 97100 | 89100 | 1.41 | |

| NF409 | 12409 | 45 | 120 | 29 | 115000 | 112000 | 1.77 | |

| NF410 | 12410 | 50 | 130 | 31 | 139000 | 136000 | 2.17 | |

| NF411 | 12411 | 55 | 140 | 33 | 142000 | 138000 | 2.71 | |

| NF412 | 12412 | 60 | 150 | 35 | 178000 | 184000 | 3.26 | |

| NF413 | 12413 | 65 | 160 | 37 | 198000 | 203000 | 3.86 | |

| NF414 | 12414 | 70 | 180 | 42 | 246000 | 257000 | 5.68 | |

| NF415 | 12415 | 75 | 190 | 45 | 265000 | 274000 | 6.74 | |

| NF416 | 12416 | 80 | 200 | 48 | 302000 | 315000 | 7.85 | |

| NF417 | 12417 | 85 | 210 | 52 | 340000 | 350000 | 9.36 | |

| NF418 | 12418 | 90 | 225 | 54 | 374000 | 400000 | 11.11 | |

| NF419 | 12419 | 95 | 240 | 55 | 410000 | 444000 | 14.67 | |

| NF420 | 12420 | 100 | 250 | 58 | 458000 | 498000 | 15.1 | |

| NF421 | 12421 | 105 | 260 | 60 | 471000 | 510000 | 20.61 | |

| NF422 | 12422 | 110 | 280 | 65 | 550000 | 621000 | 21.47 | |

| NF424 | 12424 | 120 | 310 | 72 | 690000 | 770000 | 30.16 | |

| NF426 | 12426 | 130 | 340 | 78 | 771000 | 876000 | 39 | |

| NF428 | 12428 | 140 | 360 | 82 | 874000 | 1020000 | 50.5 | |

| NF430 | 12430 | 150 | 380 | 85 | 930000 | 1120000 | 57.4 | |

Reviews

There are no reviews yet.