Description

Basic Parameters

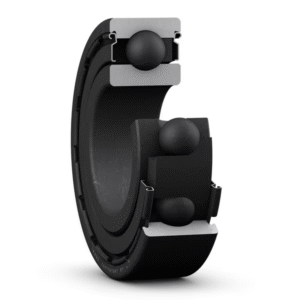

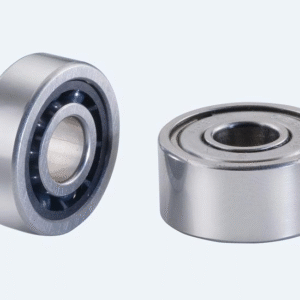

In Ceramic Bearings: 6000, “6”: Indicates that the bearing type is a deep groove ball bearing. Unlike traditional steel bearings, ceramic deep groove ball bearings offer excellent corrosion resistance, high hardness, and low friction characteristics. These properties make them ideal for applications where exposure to harsh environments or high – speed operation is required, as they can reduce wear and energy consumption.

“0”: Represents the bearing’s diameter series code. The 0 series for the diameter indicates that the bearing’s dimensions fall into the extra light or light series, which is beneficial for applications where space is limited and a lightweight solution is needed.

“00”: Is the bearing’s inner diameter code. By the common calculation rule (inner diameter = code × 5), for the 6000 ceramic bearing, its inner diameter is 00 × 5 = 10mm.

In the model 6000 ceramic bearing, the tolerance grade is not directly shown. Generally, it can be assumed to be grade 0, which is the standard precision level. The tolerance grade determines the dimensional and rotational accuracy of the bearing, and grade 0 meets the normal requirements for a wide range of general applications.

In conclusion, the Ceramic Bearings: 6000 means a deep groove ball bearing of the extra light or light series with an inner diameter of 10mm and normal precision. This type of ceramic bearing is suitable for various applications such as high – speed precision machinery, semiconductor manufacturing equipment, and medical instruments, where its unique properties can significantly enhance the performance and lifespan of the equipment.

Product Application

The Ceramic Bearings: 6000 finds extensive use across diverse industries. In semiconductor manufacturing, its high hardness and corrosion resistance ensure stable operation in cleanroom environments filled with chemicals and gases, preventing contamination and maintaining the precision of chip – making processes. High – speed precision machinery benefits from its low – friction property, enabling smooth and efficient rotation at high speeds, reducing energy consumption and wear, and enhancing the overall performance and lifespan of the equipment.

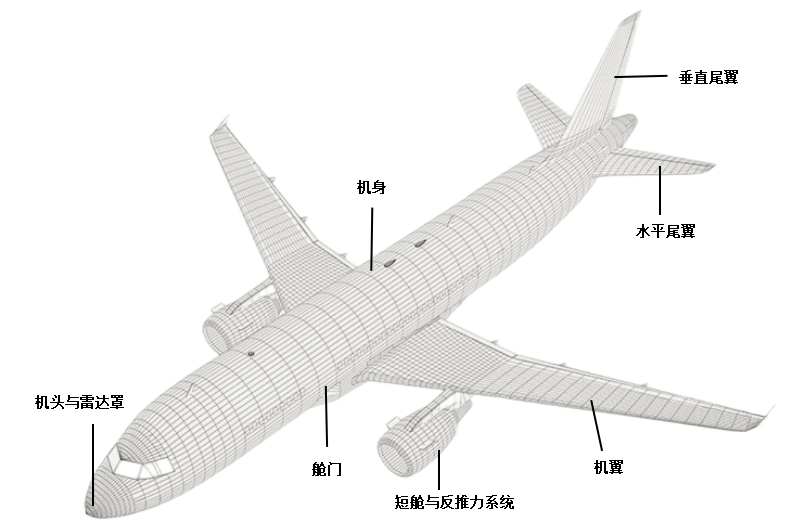

In the medical field, such as in surgical robots and diagnostic instruments, the Ceramic Bearings: 6000’s biocompatibility and high precision contribute to accurate and reliable operation, ensuring patient safety and treatment effectiveness. Textile machinery also takes advantage of these bearings, as their durability and resistance to fiber – induced abrasion help maintain production efficiency and reduce maintenance frequency. Additionally, they are employed in aerospace components, where their lightweight and high – performance characteristics meet the strict requirements for fuel efficiency and reliability in extreme conditions.

Product List

| 6000 SERIES | |||||||||

| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight (kg) | ||||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | |||

| 6000 | 100 | 10 | 26 | 8 | 4620 | 1960 | 0.020 | ||

| 6001 | 101 | 12 | 28 | 8 | 5070 | 2360 | 0.021 | ||

| 6002 | 102 | 15 | 32 | 9 | 5590 | 2850 | 0.032 | ||

| 6003 | 103 | 17 | 35 | 10 | 6050 | 3250 | 0.039 | ||

| 6004 | 104 | 20 | 42 | 12 | 9360 | 5000 | 0.070 | ||

| 6005 | 105 | 25 | 47 | 12 | 11200 | 6550 | 0.082 | ||

| 6006 | 106 | 30 | 55 | 13 | 13300 | 8300 | 0.124 | ||

| 6007 | 107 | 35 | 62 | 14 | 15900 | 10200 | 0.161 | ||

| 6008 | 108 | 40 | 68 | 15 | 16800 | 11600 | 0.197 | ||

| 6009 | 109 | 45 | 75 | 16 | 20800 | 14600 | 0.254 | ||

| 6010 | 110 | 50 | 80 | 16 | 21600 | 16000 | 0.279 | ||

| 6011 | 111 | 55 | 90 | 18 | 28100 | 21200 | 0.405 | ||

| 6012 | 112 | 60 | 95 | 18 | 29600 | 23200 | 0.428 | ||

| 6013 | 113 | 65 | 100 | 18 | 30700 | 25000 | 0.458 | ||

| 6014 | 114 | 70 | 110 | 20 | 37700 | 31000 | 0.635 | ||

| 6015 | 115 | 75 | 115 | 20 | 39700 | 33500 | 0.673 | ||

| 6016 | 116 | 80 | 125 | 22 | 47500 | 40000 | 0.877 | ||

| 6017 | 117 | 85 | 130 | 22 | 49400 | 43000 | 0.932 | ||

| 6018 | 118 | 90 | 140 | 24 | 58500 | 50000 | 1.190 | ||

| 6019 | 119 | 95 | 145 | 24 | 60500 | 54000 | 1.247 | ||

| 6020 | 120 | 100 | 150 | 24 | 60500 | 54000 | 1.340 | ||

| 6021 | 121 | 105 | 160 | 26 | 72800 | 65500 | 1.690 | ||

| 6022 | 122 | 110 | 170 | 28 | 81900 | 73500 | 2.023 | ||

| 6024 | 124 | 120 | 180 | 28 | 85200 | 80000 | 2.213 | ||

| 6026 | 126 | 130 | 200 | 33 | 104000 | 100000 | 3.270 | ||

| 6028 | 128 | 140 | 210 | 33 | 110000 | 109000 | 3.547 | ||

| 6030 | 130 | 150 | 225 | 35 | 131000 | 124000 | 4.880 | ||

| 6032 | 132 | 160 | 240 | 38 | 136000 | 135000 | 6.073 | ||

| 6034 | 134 | 170 | 260 | 42 | 168000 | 173000 | 7.175 | ||

| 6036 | 136 | 180 | 280 | 46 | 180000 | 184000 | 10.570 | ||

| 6038 | 138 | 190 | 290 | 46 | 188000 | 200000 | 11.08 | ||

| 6040 | 140 | 200 | 310 | 51 | 201000 | 222000 | 14.100 | ||

| 6044 | 144 | 220 | 340 | 56 | 247000 | 290000 | 18.500 | ||

| 6048 | 148 | 240 | 360 | 56 | 255000 | 315000 | 20.000 | ||

| 6052 | 152 | 260 | 400 | 65 | 291000 | 375000 | 28.500 | ||

| 6056 | 156 | 280 | 420 | 65 | 325000 | 420000 | 31.000 | ||

| 6060 | 160 | 300 | 460 | 74 | 355000 | 480000 | 43.500 | ||

| 6064 | 164 | 320 | 480 | 74 | 371000 | 540000 | 46.000 | ||

| 6068 | 168 | 340 | 520 | 82 | 423000 | 640000 | 62.000 | ||

| 6072 | 172 | 360 | 540 | 82 | 462000 | 735000 | 64.500 | ||

| 6076 | 176 | 380 | 560 | 82 | 470000 | 750000 | 67.500 | ||

| 6080 | 180 | 400 | 600 | 90 | 520000 | 865000 | 87.500 | ||

| 6084 | 184 | 420 | 620 | 90 | 530000 | 895000 | 91.000 | ||

Reviews

There are no reviews yet.