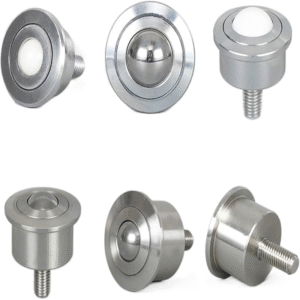

Description

Basic Parameters

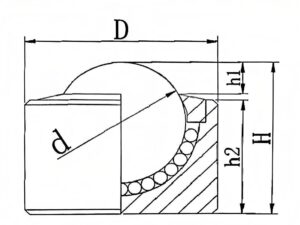

The KSM-8 Universal Ball Bearing is a precision-engineered component designed for versatile industrial applications. It features a compact design with a main ball diameter of 8 mm 4, outer diameter of 12 mm, and overall width of 10.3 mm 4. Constructed from high-quality materials, it is available in carbon steel (BS/CS) for general-purpose use or stainless steel (SS/SS) for corrosion resistance 4. The bearing supports a suggested load capacity of 5 kg and a maximum load capacity of 10 kg 34, making it suitable for light to moderate duty applications. With a deep groove configuration, it efficiently handles both radial and axial loads while maintaining smooth rotation 15. The bearing is designed for open operation (unsealed) unless specified otherwise, allowing for easy maintenance and compatibility with various lubrication systems 29. While exact speed ratings are not explicitly listed, similar KSM-series bearings are known for high-speed performance 17, and it adheres to standard precision (P0) tolerance levels 29. Its robust design and dimensional stability make it ideal for use in conveyor systems, packaging machinery, and other industrial equipment requiring reliable motion control.

Product Application

The KSM-8 Universal Ball Bearing, with its compact 8mm ball diameter and lightweight design, excels in applications requiring seamless multidirectional movement, precision, and durability. Here’s a breakdown of its real-world utility across diverse sectors:

In manufacturing and logistics, KSM-8 serves as the backbone of modular conveyor systems and assembly line workstations. Its low-profile design (12mm OD, 10.3mm width) fits into tight spaces, enabling smooth sliding of lightweight trays, electronics components, or packaged goods—ideal for e-commerce sorting hubs or food processing lines where hygiene (via stainless steel variant) and low friction are critical. For example, in a bakery’s packaging area, KSM-8-equipped tables allow operators to effortlessly pivot trays of delicate pastries, reducing manual strain and downtime.

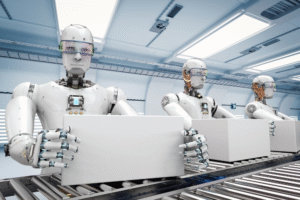

In collaborative robots (cobots) and pick-and-place machines, KSM-8 supports articulated joints and end-effectors, delivering precise rotational freedom while handling moderate loads (up to 10kg max). Its deep-groove design minimizes vibration, making it suitable for electronics assembly—such as aligning microchips on PCBs—or automotive component testing, where repeated motion demands reliability. A notable use case: integrating KSM-8 into a warehouse’s automated guided vehicle (AGV) turntable to enable 360° pallet rotation with minimal energy loss.

From supermarket checkout counters to library book return systems, KSM-8 simplifies user interaction. Its open-design (unsealed by default) allows easy cleaning, crucial for environments like grocery stores where spills are common. For instance, a retail display’s sliding shelf, embedded with KSM-8 bearings, lets staff restock items with fingertip ease, enhancing ergonomics. In hospitality, it’s used in portable food carts to ensure trays glide smoothly during service, even on uneven floors.

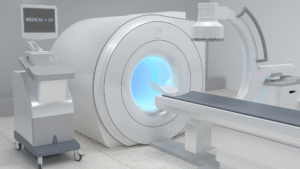

In medical settings, the stainless steel KSM-8 variant features in surgical table accessories and laboratory centrifuges, combining corrosion resistance with operation. Its precision tolerance (P0 standard) ensures stable movement in diagnostic equipment, such as biopsy tray adjusters. In industrial machinery, it supports textile loom shuttles and printing press rollers, where consistent lateral movement prevents material jams—a boon for high-speed production lines.

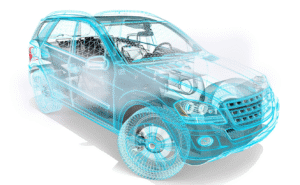

KSM-8’s durability shines in automotive interiors (e.g., adjustable cup holders, seat track mechanisms) and light-duty vehicles like electric scooters, where space is constrained. Its ability to handle radial/axial loads makes it ideal for small 万向 joints in steering linkages, ensuring responsive maneuverability. For example, a foldable wheelchair’s footrest pivot, reinforced with KSM-8, withstands daily stress while maintaining smooth operation.

Engineers and DIY enthusiasts favor KSM-8 for custom jigs and prototypes due to its affordability and ease of integration. Whether retrofitting a woodworking bench’s workpiece support or creating a prototype for a smart home device, its standardized dimensions (compatible with M8 screws) and open design allow rapid iteration—no specialized tools required.

Product List

Model

No.KSM |

Ball

Material |

Loading Capacity (kg) |

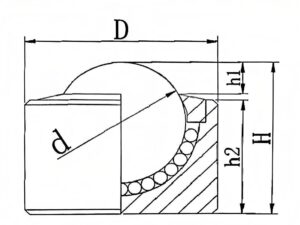

Dimensions (mm) |

weight(g) |

| Suggest |

Max. |

d |

D |

h1 |

h2 |

H |

| KSM-8 |

Chrome Steel |

5kg |

8kg |

7.14 |

12 |

2.3 |

8 |

10.3 |

6g |

| Stainless Steel |

3kg |

5kg |

| POM |

3kg |

3kg |

5.7g |

| KSM-12 |

Chrome Steel |

25kg |

30kg |

12 |

22 |

2.5 |

13.5 |

17 |

39g |

| Stainless Steel |

20kg |

25kg |

| POM |

10kg |

15kg |

33g |

| KSM-15 |

Chrome Steel |

40kg |

50kg |

15.88 |

24 |

4 |

15 |

20 |

45g |

| Stainless Steel |

30kg |

40kg |

| POM |

20kg |

30kg |

34g |

| KSM-19 |

Chrome Steel |

60kg |

80kg |

19.05 |

28 |

4.5 |

18.5 |

24.5 |

87g |

| Stainless Steel |

50kg |

60kg |

| POM |

50kg |

60kg |

63g |

| KSM-22 |

Chrome Steel |

90kg |

100kg |

22.22 |

36 |

6 |

23.5 |

31 |

187g |

| Stainless Steel |

70kg |

80kg |

| POM |

60kg |

70kg |

150g |

| KSM-25 |

Chrome Steel |

130kg |

150kg |

25.4 |

37 |

6.5 |

23 |

31 |

230g |

| Stainless Steel |

100kg |

120kg |

| POM |

80kg |

100kg |

176g |

| KSM-30 |

Chrome Steel |

250kg |

300kg |

30.16 |

45 |

8 |

27 |

38 |

340g |

| Stainless Steel |

200kg |

250kg |

| POM |

100kg |

130kg |

248g |

| KSM-38 |

Chrome Steel |

300kg |

350kg |

38.1 |

55 |

9.5 |

33.5 |

48 |

638g |

| Stainless Steel |

220kg |

280kg |

| POM |

130kg |

150kg |

454g |

| KSM-45 |

Chrome Steel |

400kg |

450kg |

45 |

62 |

11 |

37.6 |

53.4 |

910g |

| Stainless Steel |

300kg |

350kg |

| KSM-60 |

Chrome Steel |

1000kg |

1400kg |

60 |

100 |

20 |

55.5 |

77.5 |

2100g |

| Stainless Steel |

600kg |

800kg |

Reviews

There are no reviews yet.