Description

Basic Parameters

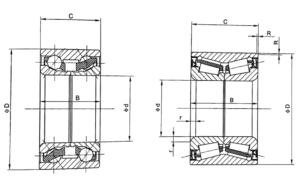

The Bearing Housing SN is a rugged industrial solution designed to securely support rolling element bearings in various mechanical setups. Constructed from high-grade cast iron, it offers superior structural integrity and resistance to impact, making it suitable for demanding operational environments. Its precision-machined inner bore ensures accurate bearing alignment, reducing rotational friction and enhancing long-term performance. Engineered to operate within a service temperature range of -20°C to +120°C, the housing withstands moderate thermal fluctuations commonly encountered in industrial applications. Maintenance efficiency is prioritized through integrated lubrication ports, allowing easy access for grease replenishment without disassembling the system, which minimizes downtime in continuous operations. The surface is treated with an anti-corrosive coating to protect against rust and environmental degradation in humid, dusty, or chemically exposed settings. Designed for universal compatibility, it works seamlessly with standard ball, roller, or tapered bearings, fitting into machinery such as conveyors, pumps, electric motors, and gearboxes. Its robust design and ease of installation make it a reliable choice for maintaining the stability and longevity of rotating equipment across manufacturing, material handling, and process industries.

Product Application

1. Core Industrial Sectors & Machinery Integration

Manufacturing & Production: Conveyors, assembly lines, machine tools (lathes, mills), and packaging equipment, where precise bearing alignment is essential for reducing vibration and enhancing machining accuracy.

Energy & Utilities: Wind turbines, generators, pumps in power plants, and hydroelectric systems, supporting high-load rotational components in harsh, high-temperature, or moisture-rich environments.

Material Handling: Cranes, forklifts, warehouse racking systems, and port machinery, ensuring reliable operation under heavy dynamic loads and frequent start-stop cycles.

Process Industries: Chemical plants, food & beverage production, and mining equipment, where resistance to corrosion, dust, and abrasive particles is critical for long-term durability.

Transportation: Railway locomotives (wheel bearings), marine propulsion systems, and automotive manufacturing equipment, enduring shock loads and extreme temperature fluctuations.

2. Typical Mechanical System Applications

Rotating Shaft Support: Integrates with ball bearings, roller bearings, or tapered bearings to stabilize shafts in motors, gearboxes, and pumps, minimizing radial/axial movement and reducing wear.

Conveyor Systems: Supports rollers and pulleys in belt/chain conveyors for logistics, agriculture, and recycling, ensuring smooth material transport even under uneven or heavy loads.

Fluid Handling Equipment: Used in centrifugal pumps, compressors, and mixers to maintain bearing precision during fluid/gas transfer, preventing leakage and energy loss from misalignment.

Heavy Machinery: Enhances the reliability of crushers, screens, and excavators in mining/construction by withstanding high-impact loads and abrasive conditions, reducing downtime for maintenance.

Aerospace & Defense: Specialized housings for aircraft ground support equipment and military vehicles, engineered for lightweight strength and resistance to extreme environmental stress.

3. Key Application Advantages

Durability & Structural Strength: Constructed from high-grade materials (cast iron, steel, or aluminum alloy) to withstand heavy loads, impact, and cyclic stress, ensuring long service life in demanding environments.

Precision Engineering: Machined bores and mounting surfaces guarantee accurate bearing alignment, reducing rotational friction and noise while improving overall system efficiency.

Environmental Adaptability:

Anti-corrosive coatings (epoxy, zinc plating) protect against rust in humid, salt-laden, or chemically aggressive settings (e.g., coastal facilities, wastewater plants).

Heat-resistant materials and designs accommodate operating temperatures from -40°C to +300°C, suitable for high-temperature applications like kilns, ovens, or engine components.

Sealing solutions (lip seals, labyrinth seals) prevent dust, water, or debris ingress in harsh environments (e.g., mining, cement production).

Maintenance Efficiency:

Integrated lubrication ports enable easy grease replenishment without disassembling the housing, critical for systems requiring minimal downtime (e.g., 24/7 production lines).

Modular designs allow quick bearing replacement, reducing maintenance labor and costs in large-scale industrial setups.

4. Specialized Adaptations for Niche Needs

High-Speed Applications: Lightweight aluminum housings with precision-balanced designs for turbines or high-speed spindles, minimizing vibration at rotational speeds exceeding 10,000 RPM.

Cleanroom Environments: Stainless steel housings with smooth surfaces and hermetic seals, compliant with ISO 14644 standards for pharmaceutical, semiconductor, or medical device manufacturing.

Offshore & Marine Use: Corrosion-resistant duplex stainless steel or polymer-composite housings, certified for saltwater exposure and marine-grade anti-fouling requirements.

Custom Configurations: Tailored mounting interfaces (flange, pillow block, or take-up styles), bearing compatibility (metric/imperial standards), and housing geometries to fit unique machinery designs.

5. Industry Standards & Global Compatibility

Pillow Block Housings: Ideal for exposed shaft applications with easy access for alignment adjustments.

Flanged Housings: Space-efficient solutions for compact machinery requiring side-mounted installation.

Take-Up Housings: Used in belt-driven systems to tension and support idler pulleys.

Product List

| Housing No. |

Shaft Dia d1 |

Dimensions(mm) | Housing wt (kg) |

||||||||||||||||||

| mm | in | D H8 |

a | b | c | g H12 | h h12 |

L | L1 | W | m | n | u | v | s | d2 H12 |

d3 H12 |

f1 H12 | f2 | ||

| SN605 | 20 | 3/4 | 62 | 185 | 52 | 22 | 34 | 50 | 80 | 83 | 90 | 150 | 25 | 15 | 20 | M12 | 21.5 | 31 | 3 | 4.2 | 2.1 |

| SN606 | 25 | 1 | 72 | 185 | 52 | 22 | 37 | 50 | 82 | 85 | 95 | 150 | 25 | 15 | 20 | M12 | 26.5 | 38 | 4 | 5.4 | 3.1 |

| SN607 | 30 | 1-1/8 | 80 | 205 | 60 | 25 | 41 | 60 | 90 | 93 | 110 | 170 | 30 | 15 | 20 | M12 | 31.5 | 43 | 4 | 5.4 | 3.73 |

| SN608 | 35 | 1-1/4 | 90 | 205 | 60 | 25 | 43 | 60 | 95 | 100 | 115 | 170 | 30 | 15 | 20 | w12 | 36.5 | 48 | 4 | 5.4 | 4.6 |

| SN609 SSN609 |

40 | 1-1/2 | 100 | 255 | 70 | 28 | 46 | 70 | 105 | 110 | 130 | 210 | 35 | 18 | 23 | M16 | 41.5 | 53 | 4 | 5.4 | 5.7 8.0 |

| SN610 SSN610 |

45 | 1-3/4 | 110 | 255 | 70 | 30 | 50 | 70 | 115 | 120 | 135 | 210 | 35 | 18 | 23 | M16 | 46.5 | 58 | 4 | 5.4 | 6.5 9.0 |

| SN611 SSN611 |

50 | 2 | 120 | 275 | 80 | 30 | 53 | 80 | 120 | 125 | 150 | 230 | 40 | 18 | 23 | M16 | 51.5 | 67 | 5 | 6.9 | 6.8 9.5 |

| SN612 SSN612 |

55 | 2-1/8 | 130 | 280 | 80 | 30 | 56 | 80 | 125 | 130 | 155 | 230 | 40 | 18 | 23 | M16 | 56.5 | 72 | 5 | 6.9 | 8.6 11 |

| SN613 SSN613 |

60 | 2-1/4 | 140 | 315 | 90 | 32 | 58 | 95 | 130 | 135 | 175 | 260 | 50 | 22 | 27 | M20 | 62 | 77 | 5 | 6.8 | 11.1 14 |

| SN615 SSN615 |

65 | 2-1/2 | 160 | 345 | 100 | 35 | 65 | 100 | 140 | 145 | 195 | 290 | 50 | 22 | 27 | M20 | 67 | 82 | 5 | 6.8 | 15.2 19.1 |

| SN616 SSN616 |

70 | 2-3/4 | 170 | 345 | 100 | 35 | 68 | 112 | 145 | 150 | 212 | 290 | 50 | 22 | 27 | M20 | 72 | 89 | 6 | 8.1 | 17.8 21.2 |

| SN617 SSN617 |

75 | 3 | 180 | 380 | 110 | 40 | 70 | 112 | 155 | 160 | 218 | 320 | 60 | 26 | 32 | M24 | 77 | 94 | 6 | 8.1 | 19.5 25 |

| SN618 SSN610 |

80 | 3-1/4 | 190 | 400 | 110 | 33 | 74 | 112 | 160 | 185 | 230 | 320 | 60 | 26 | 35 | M24 | 82 | 99 | 6 | 8.1 | 25.3 29.3 |

| SN619 SSN619 |

85 | 200 | 420 | 120 | 26 | 77 | 125 | 170 | 175 | 245 | 350 | 70 | 26 | 35 | M24 | 87 | 104 | 6 | 8.1 | 27 32.3 |

|

| SN620 SSN620 |

90 | 3-1/2 | 215 | 420 | 120 | 38 | 83 | 140 | 175 | 180 | 280 | 350 | 70 | 26 | 35 | M24 | 92 | 111 | 7 | 9.3 | 32 36 |

| SN622 SSN622 |

100 | 4 | 240 | 460 | 130 | 40 | 90 | 150 | 190 | 195 | 300 | 390 | 70 | 28 | 38 | M24 | 102 | 125 | 8 | 10.8 | 43.4 51 |

| SN624 SSN624 |

110 | 4-1/4 | 260 | 540 | 160 | 50 | 96 | 160 | 205 | 210 | 325 | 450 | 90 | 33 | 42 | M30 | 113 | 135 | 8 | 10.7 | 54.6 64 |

| SN626 SSN626 |

115 | 4-1/2 | 280 | 560 | 160 | 50 | 103 | 170 | 215 | 220 | 350 | 470 | 90 | 33 | 42 | M30 | 118 | 140 | 8 | 10.7 | 67.2 78 |

| SN628 SSN628 |

125 | 5 | 300 | 630 | 170 | 55 | 112 | 180 | 235 | 240 | 375 | 520 | 90 | 35 | 45 | M30 | 128 | 154 | 9 | 12.2 | 92.6 105 |

| SN630 SSN620 |

135 | 5-1/4 | 320 | 680 | 180 | 55 | 118 | 190 | 245 | 250 | 305 | 560 | 90 | 35 | 45 | M30 | 138 | 164 | 9 | 12.2 | 101.5 113.0 |

| SN632 SSN632 |

140 | 5-1/2 | 340 | 710 | 190 | 60 | 124 | 200 | 255 | 260 | 415 | 580 | 100 | 42 | 52 | M36 | 143 | 173 | 10 | 13.7 | 122.3 135.6 |

Reviews

There are no reviews yet.