Description

Product Positioning

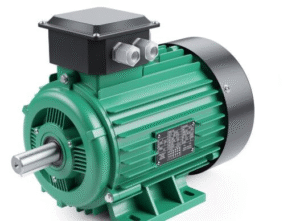

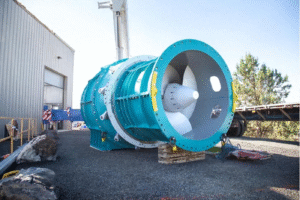

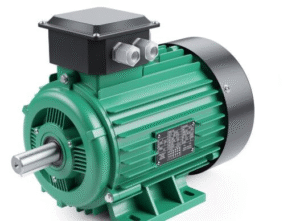

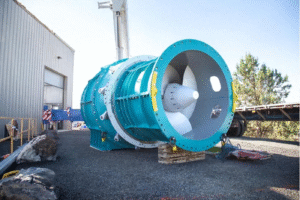

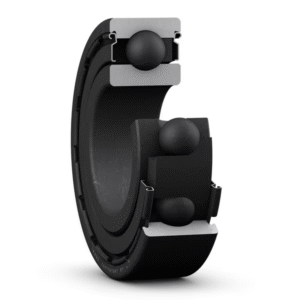

The 6206-2Z/VA228 Me is a deep groove ball bearing specifically designed for high-temperature, heavy-load, and low-maintenance industrial scenarios. Leveraging specialized material technology and structural optimization, it delivers stable power transmission under extreme temperature conditions. It is ideal for key equipment such as fans, generators, industrial ovens, and vibrating screens, serving as a preferred alternative to standard bearings to reduce failure risks in high-temperature operations.

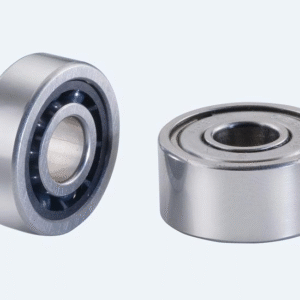

- Standardized Basic Dimensions: 30mm inner diameter, 62mm outer diameter, and 16mm width. Fully compatible with the installation dimensions of standard deep groove ball bearings, eliminating the need for equipment interface modifications and minimizing replacement costs.

- Double-Sided Metal Shielding (-2Z): Equipped with high-toughness steel plate shields that fit tightly to the bearing rings. Effectively blocks the ingress of dust, debris, and coolant while retaining internal lubricant to reduce grease loss.

- Graphite Self-Lubricating Cage (Core Configuration of VA228): The crown-shaped graphite cage has inherent lubricating properties, eliminating the need for frequent grease replenishment. It maintains smooth rotation within the temperature range of -20℃ to +350℃, solving the problem of grease failure under high temperatures.

- Manganese Phosphate Surface Hardening: The bearing rings and rolling elements undergo manganese phosphate treatment to form a dense wear-resistant protective layer. This not only enhances resistance to high-temperature oxidation but also reduces metal-to-metal friction and wear, extending service life.

- C5-Class Expansion Internal Clearance: Adopts radial internal clearance larger than the standard group, which fully compensates for thermal expansion of bearing components under high temperatures. Prevents jamming or seizure caused by thermal expansion and contraction, ensuring continuous equipment operation.

Tailored for high-frequency applications such as industrial motors and gearboxes, with optimized internal geometric accuracy of the bearing:

- Reduces operating noise (suitable for noise-sensitive equipment);

- Enhances radial load-carrying capacity (capable of handling moderate radial loads + bidirectional axial loads, adapting to multi-condition transmission needs).

- High-temperature transmission equipment: Oven conveyor motors, furnace exhaust fans, tube mill transmission systems;

- Heavy industrial equipment: Vibrating screen spindles, high-speed gearbox shafts, generator bearing positions;

- Harsh-environment equipment: Mining machinery with high dust levels, machine tool spindles with coolant (requires dust-proof configuration).

Reviews

There are no reviews yet.