Description

Basic Parameters

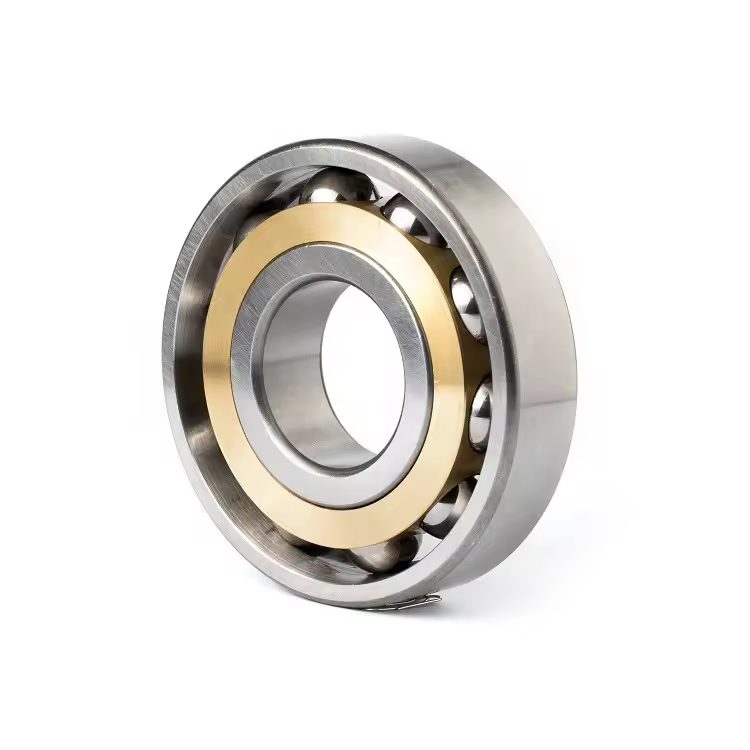

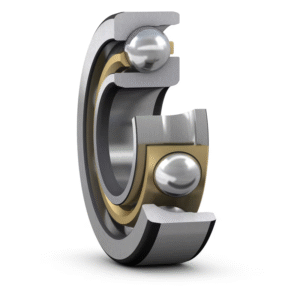

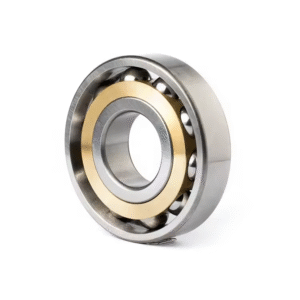

The FODA Bearing 120BA10XTY Angular Contact Ball Bearing features a 120 mm inner diameter, 180 mm outer diameter, and 27 mm width. Manufactured from high-quality chrome steel (GCr15), it offers excellent strength and wear resistance. With a typical 30° contact angle, it is designed to accommodate both radial and axial loads while operating at high rotational speeds. Built to P4 precision standards, this bearing delivers low noise, minimal vibration, and exceptional stability — making it ideal for CNC machine spindles, precision instruments, and high-speed transmission systems.

Product Advantages

Extended Service Life: Based on high-purity steel and anti-fatigue technology, the basic rated life (L10) of this bearing is 2000 hours. Under clean and non-impact working conditions, the actual service life can be extended to more than 3000 hours, reducing equipment replacement costs.

Strong Environmental Adaptability: It has a wide temperature resistance range (-40℃~120℃) and is suitable for high and low-temperature industrial environments; the sealing structure can resist IP54-level dust and splashing water erosion, making it applicable to dusty or humid scenarios such as machine tool processing and auto parts.

High Installation Convenience: Adopts a separable inner ring design. During installation, the fit clearance between the inner ring and the shaft can be adjusted independently without disassembling the entire bearing. It is suitable for a variety of shaft diameter specifications (adaptable shaft diameter range 10-12mm), reducing the difficulty of installation operations.

Product Applications

Machine Tool Equipment Field: Suitable for spindle of small CNC lathes, feed shafts of CNC milling machines, grinding wheel shafts of grinding machines, etc. It can meet the strict requirements of precision machining for speed (2000-3600r/min) and accuracy (positioning error ≤0.002mm), improving the surface finish of processed parts.

Industrial Motor Field: Used for rotor shaft support of servo motors and stepping motors, especially small drive motors (power 0.5-2.2kW) in automated equipment. It can reduce motor operating noise, improve torque transmission efficiency, and ensure the continuous and stable operation of the motor.

Precision Instrument Field: Applied to the transmission mechanism of optical measuring instruments (such as projectors, coordinate measuring machines) and rotating components of medical equipment (such as small diagnostic instruments). With low vibration and high precision characteristics, it ensures the accuracy of instrument measurement data.

Automotive Components Field: Suitable for the auxiliary motor shaft of the automotive electric power steering system (EPS) and the main shaft of the automotive air conditioning compressor. It can resist high temperatures (≤100℃) and vibration environments in the engine compartment, ensuring the reliable operation of the steering and refrigeration systems.

Electronic Equipment Field: Used for the drive shaft of printer toner cartridges, rotor shafts of small fans, etc. The lightweight cage and low-friction design can reduce equipment energy consumption, adapting to the “small size, low noise” usage requirements of electronic equipment.

Reviews

There are no reviews yet.