Description

Characteristics

1.Convenient installation: The installation process of the tight sleeve and the shirking sleeve is relatively simple, and there is no need for excessive processing of the shaft.

2. Fixed and reliable: the bearing can be firmly fixed on the shaft to ensure that the bearing will not be displaced during operation.

3. Easy disassembly: the shirking sleeve makes the disassembly of the bearing easier, reducing the risk of damage to the shaft and bearing.

4. Wide applicability: suitable for various types of bearings and shafts of different diameters.

Classification

1. Set Sleeves

Designed for mounting cylindrical bore bearings on tapered shafts, featuring a tapered inner bore and locking nut to secure the bearing axially.

Commonly used in light to medium-duty applications (e.g., motors, pumps).

Fitted onto tapered shaft journals, allowing easy removal of bearings with a tapered bore.

Typically used in heavy-duty machinery requiring frequent maintenance (e.g., mining equipment, industrial gearboxes).

Integrated with a locknut and washer for precise axial positioning, suitable for high-vibration environments.

Carbon steel (standard durability)

Alloy steel (enhanced strength for heavy loads)

Stainless steel (corrosion resistance for harsh environments).

2. Release Sleeves

Utilize hydraulic pressure to create a gap between the sleeve and shaft, enabling non-destructive bearing removal.

Ideal for large bearings in wind turbines, heavy machinery.

Feature threaded holes or puller slots for mechanical extraction via pullers or jacks.

Common in medium-sized bearings (e.g., automotive transmissions, construction equipment).

Matched with tapered bore bearings, allowing controlled disassembly by adjusting axial force.

Used in applications requiring precise fit (e.g., printing presses, turbines).

Combined with mounting accessories (e.g., withdrawal collars, adapter rings) for complete disassembly solutions.

3. Combined Classification by Application

Industrial Machinery Series

Heavy-duty set/release sleeves for manufacturing equipment, crushers, and conveyors.

Automotive Series

Compact designs for wheel bearings, drivetrain components.

Renewable Energy Series

High-load hydraulic release sleeves for wind turbine hubs.

Basic Parameters

Bearing set sleeves and release sleeves are typically constructed from high-strength alloy steel (e.g., 20CrMnTi, GCr15) with surface quenching for enhanced hardness (HRC 58-62), offering dimensional ranges from bore diameters 20mm to 500mm and outer diameters up to 800mm, compatible with tapered bore bearings (taper ratio 1:12 or 1:30). They support radial loads up to 2000kN and axial loads up to 500kN (depending on size and design), meeting precision classesISO P0 to P6 for general industrial to moderate-precision applications. Features include threaded ends for locknut installation, hydraulic ports (for release sleeves), or puller slots for mechanical disassembly, with surface treatments like zinc plating or anti-corrosive coatings for harsh environments. Standard compliance covers ISO 113/ISO 355 for dimensional compatibility and AGMA 9005 for load ratings, ensuring seamless integration with rolling bearings such as spherical roller, tapered roller, or cylindrical roller types.

The Working Principle

Application Fields

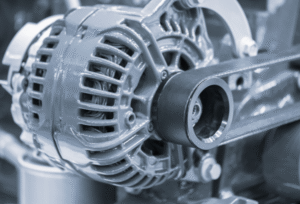

1.Industrial machinery: such as various transmission equipment, pumps, fans, etc.

2. Mining machinery: used for crusher, conveyor and other equipment bearing fixing and disassembly.

3. Agricultural machinery: widely used in tractors, harvesters and other equipment.

4. Automobile manufacturing: used for bearing installation and disassembly of automobile engine, transmission and other components.

5. Other areas: such as motors, power tools, etc., will also use tight sets and shirking sets.

Reviews

There are no reviews yet.