Description

Advantages of Custom Bearings

Custom bearings, designed to address specific requirements unmet by standard off-the-shelf components, offer distinct advantages: they can be tailored in materials and structures to suit precise operational needs like load capacity, speed, temperature, and environmental conditions—for example, reinforced materials for high-load scenarios or corrosion-resistant alloys for harsh environments. Performance is optimized through features like refined raceway profiles and surface treatments to reduce friction and energy loss, while seamless compatibility with non-standard equipment dimensions or compact spaces eliminates costly retrofitting. Premium materials (e.g., ceramics, high-strength steel) and designs like self-lubrication or sealed configurations extend service life, minimizing maintenance and replacements to lower total cost of ownership. They also support innovation in sectors like renewable energy and semiconductors, leveraging manufacturers’ expertise in material science and engineering design to adapt to complex loads and non-traditional motion patterns, serving as the key solution where standard components fall short.

FODA’s Customization Capabilities

Custom bearings are designed specifically to meet the requirements that most standard bearings cannot fulfill. Unlike standard bearings, our custom options are specifically tailored to your needs through a comprehensive customization process. Our goal is always to provide you with products that perform well, have a long service life, and meet your exact specifications.Our bearings are designed and manufactured in a wide range of sizes to meet the needs of all types of applications. From consumer products to aerospace components to high-precision bearings for machinery, we can meet your requirements.FODA Bearing’s Design Capabilities:With over 20 years of experience and extensive design capabilities, It helps us meet different application needs.

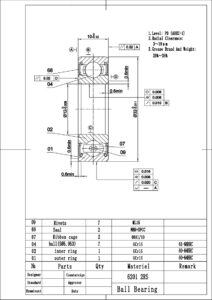

Customization according to drawings

1.Drawing Receipt and Review

Receipt of Drawings: Clients transmit detailed bearing design drawings to the company via email, postal mail, or other methods. Seasoned engineers will conduct a review of the drawings to examine their clarity and completeness. This involves confirming that dimensional annotations are explicit, tolerance ranges are reasonable, and technical specifications are clearly discernible. In the event of any uncertainties, timely communication will be initiated with clients to obtain accurate information.

2.Material Preparation, Mold Making, and Processing:

In accordance with the technical requirements specified in the drawings, the company will select qualified suppliers to procure raw materials based on the specifications outlined in the evaluation report. We will rigorously verify quality certifications, conduct batch sampling to ensure compliance with chemical composition standards, and test mechanical properties using hardness and tensile testing machines before the materials are warehoused. For samples requiring molds, the design team will develop plans considering the shape, dimensions, and processing technology, while also taking into account factors such as strength, precision, wear resistance, and ease of demolding. These plans will be finalized through multi-departmental reviews before part processing commences. All processes adhere to customer standards regarding dimensions, material properties, and load-bearing capacity, ensuring dimensional accuracy, structural strength, and assembly suitability with compliant shape and surface roughness.

3. 1:1 Scale Reproduction Of The Drawing

After completing part processing, strict quality inspections are carried out to ensure that each part’s dimensional accuracy, shape precision, surface roughness, and material properties are identical to the sample. Qualified parts passing inspection are pre-assembled to check the fit precision and assembly effect between components. Through fine-tuning of part processing dimensions or optimization of the assembly process, the pre-assembled product achieves 1:1 replication of the drawing in terms of appearance, structure, and performance.

4.Finished Product Inspection

5.Enter production

If the customer is satisfied with the sample inspection results, the company will formulate a detailed production plan based on the order quantity and rationally allocate production equipment and personnel. During production, we strictly adhere to the same process standards and quality control procedures as those used for sample processing, inspecting each batch of raw materials and monitoring the quality of key processes in real time. According to the production schedule and order delivery timeline, we will reasonably adjust the production pace to ensure that order production tasks are completed on time and in the required quantity.

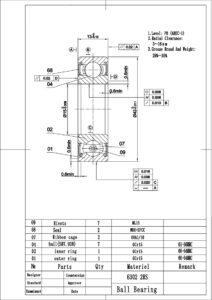

Customization according to samples

1.Customer Sample Submission:

Customers shall send the bearing samples to be processed to FODA BEARING. Upon receipt of the samples, dedicated personnel will be responsible for receipt registration, recording key information such as the receipt date, sender details, sample name, and quantity. We ensure that the samples remain undamaged during transportation. In case of any abnormalities, we will promptly communicate with the customer.

2.Sample Evaluation:

FODA BEARING will promptly assemble an experienced engineering and technical team to conduct a comprehensive and meticulous evaluation of the samples. High-precision measuring instruments will be used to accurately measure all dimensions of the samples, including inner diameter, outer diameter, width, raceway diameter, etc., with errors controlled within a minimal range. Meanwhile, equipment such as metallographic analyzers and hardness testers will be employed to analyze the material composition, hardness, and structural characteristics of the samples. The team will conduct in-depth research on the structural design of the samples to assess their rationality and machinability. For complex samples or those with special requirements, technical personnel will further communicate with customers to clarify technical details and quality standards, and prepare detailed evaluation reports to provide a basis for formulating subsequent processing techniques.

3.Material Preparation, Mold Making, and Processing:

4. 1:1 Sample Replication:

5.Sample Production and Submission for Customer Quality Inspection:

6.Enter production

Customozation according to requirement

We can determine the required radial and axial loads based on the client’s load requirements, assess the operating speed and precision requirements according to speed specifications, consider temperature, corrosion resistance, and lubrication needs based on environmental conditions, and select suitable materials for the application according to material properties to ensure they meet specific requirements.FODA Bearings, we have achieved success in the custom bearing market because we are committed to perfect engineering design, the most advanced manufacturing capabilities, and a customer-centric approach. With a wealth of options and a customized approach, we are dedicated to providing high-performance and reliable bearing solutions for various applications. Contact us today to learn more about our bearing custom manufacturing capabilities.

Application

1. Aerospace and Defense: Reliability in Extreme Environments

2. Renewable Energy & Green Technology: Core Support for High-Efficiency Conversion

Wind turbine yaw/pitch systems (large diameters, variable loads), hydrogen fuel cell air compressors (ultra-high speeds, oil-free lubrication), and solar tracker supports (lightweight, long-life).

3. Precision Instruments & Semiconductors: Industrial Hearts for Nanometer Accuracy

Wafer stage positioning in lithography machines (nanometer precision), CMM rotating axes, and high-temperature bearings in semiconductor ion implanters.

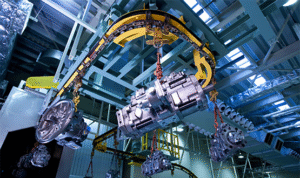

4. Heavy Industry & Special Machinery: Industrial Backbones for Heavy Loads and Wear Resistance

Mining excavator slewing rings (500-ton loads), metallurgical continuous casting roller bearings (high-temperature + dust), and port crane luffing bearings (alternating loads + high impact).

Reviews

There are no reviews yet.