Description

Basic Parameters

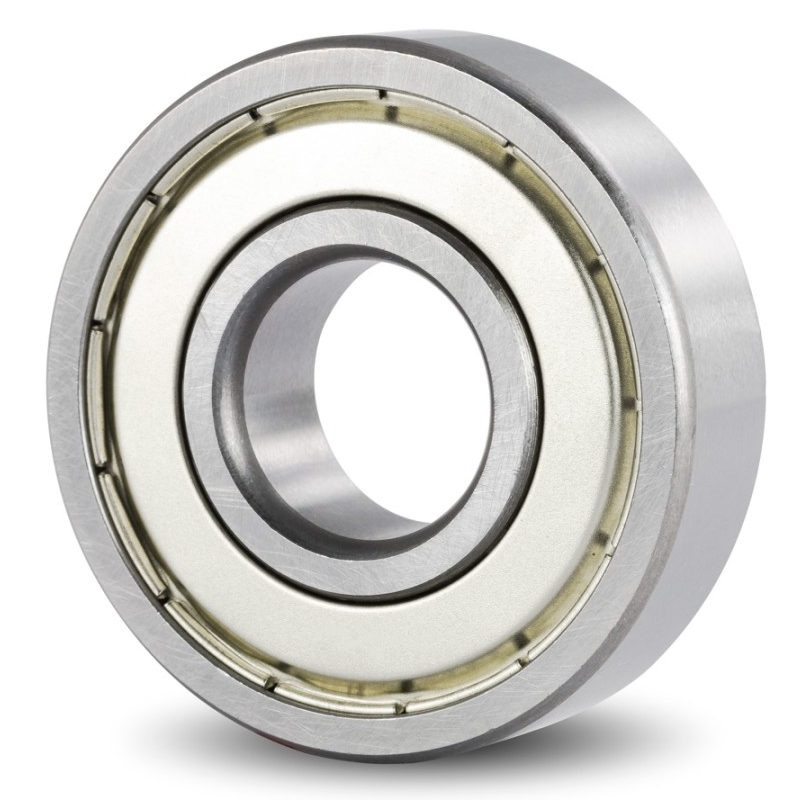

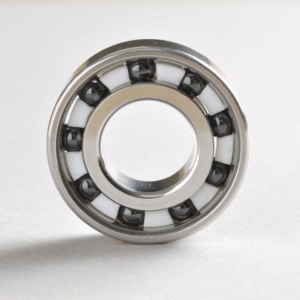

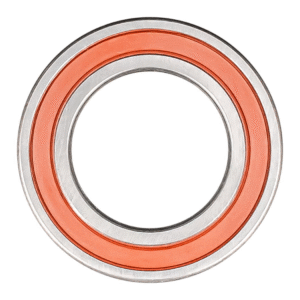

6: Indicates that the bearing type is a deep groove ball bearing, the most common type of rolling bearings, known for their simple structure and ease of use. They primarily bear radial loads and can also withstand a certain amount of axial load.

3: Indicates the bearing’s diameter series code, which represents the relative size range of the inner and outer diameters. The “3” series corresponds to the medium series, meaning the bearing has a moderate size between light and heavy series in terms of overall dimensions.

12: Indicates the bearing’s inner diameter code. For standard inner diameter coding, the actual inner diameter is calculated as code × 5 mm. Thus, the inner diameter of the 6312 bearing is 12 × 5 = 60 mm.

The tolerance grade is not explicitly indicated in the model “6312” and is typically assumed to be grade 0 (normal precision level), which meets general dimensional and rotational accuracy requirements for most applications.

Product Application

1. Electric Motors & Generators

Application: Commonly used in induction motors, servo motors, and generator systems.

Advantage: Handles the radial loads generated by rotating armatures and shafts while accommodating minor axial forces from belt drives or gear couplings. Its low friction and high limiting speed (up to 6,300 rpm with oil lubrication) ensure efficient energy transfer and minimal heat generation in high-speed motor operations.

2. Pumps & Compressors

Application: Installed in centrifugal pumps, water pumps, and air compressors.

Advantage: Withstands radial loads from impeller imbalance and moderate axial thrust from fluid pressure. The bearing’s simple structure and ease of installation facilitate maintenance in wet or dusty environments, where reliability and resistance to contamination are critical.

3. Conveyor Systems & Material Handling

Application: Used in belt conveyors, roller conveyors, and automated systems (warehouse automation).

Advantage: Supports the weight of conveyed materials and the rotational load of rollers/shafts. Its ability to operate with minimal lubrication (suitable for grease or oil) makes it ideal for long-span conveyor systems where maintenance access is limited.

4. Industrial Machinery & Equipment

Application: Found in gearboxes, reducers, printing presses, and packaging machines.

Advantage: Combines radial load capacity with the flexibility to handle slight misalignments, ensuring stable operation in precision machinery. The bearing’s standard tolerance grade (Grade 0, normal precision) balances accuracy with cost-effectiveness for most industrial applications.

5. Agricultural Machinery

Application: Used in tractors, combines, irrigation pumps, and harvesting equipment.

Advantage: Endures harsh conditions such as dust, moisture, and variable loads. The robust outer ring and inner ring design resist shock loads from uneven terrain, while its moderate weight (1.8 kg) minimizes rotational inertia in agricultural drives.

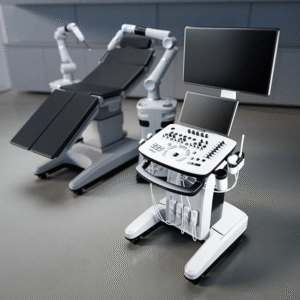

6. Power Tools & Consumer Electronics

Application: Used in high-speed drills, grinders, and precision instruments (e.g., robotics, CNC machines).

Advantage: Provides precise rotational control and durability in compact mechanical systems. The bearing’s deep groove design enhances load-carrying capacity for intermittent heavy-duty tasks, such as those encountered in power tools.

Product List

| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight (kg) | ||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | |

| 6300 | 300 | 10 | 35 | 11 | 8060 | 3400 | 0.054 |

| 6301 | 301 | 12 | 37 | 12 | 9750 | 4150 | 0.063 |

| 6302 | 302 | 15 | 42 | 13 | 11400 | 5400 | 0.087 |

| 6303 | 303 | 17 | 47 | 14 | 13500 | 6550 | 0.117 |

| 6304 | 304 | 20 | 52 | 15 | 15900 | 7800 | 0.153 |

| 6305 | 305 | 25 | 62 | 17 | 22500 | 11600 | 0.238 |

| 6306 | 306 | 30 | 72 | 19 | 28100 | 16000 | 0.360 |

| 6307 | 307 | 35 | 80 | 21 | 33200 | 19000 | 0.467 |

| 6308 | 308 | 40 | 90 | 23 | 41000 | 24000 | 0.640 |

| 6309 | 309 | 45 | 100 | 25 | 52700 | 31500 | 0.843 |

| 6310 | 310 | 50 | 110 | 27 | 61800 | 38000 | 1.097 |

| 6311 | 311 | 55 | 120 | 29 | 71500 | 45000 | 1.377 |

| 6312 | 312 | 60 | 130 | 31 | 81900 | 52000 | 1.733 |

| 6313 | 313 | 65 | 140 | 33 | 92300 | 60000 | 2.153 |

| 6314 | 314 | 70 | 150 | 35 | 104000 | 68000 | 2.560 |

| 6315 | 315 | 75 | 160 | 37 | 111400 | 76500 | 3.120 |

| 6316 | 316 | 80 | 170 | 39 | 124000 | 86500 | 3.680 |

| 6317 | 317 | 85 | 180 | 41 | 133000 | 96500 | 4.303 |

| 6318 | 318 | 90 | 190 | 43 | 143000 | 108000 | 4.967 |

| 6319 | 319 | 95 | 200 | 45 | 153000 | 118000 | 5.710 |

| 6320 | 320 | 100 | 215 | 47 | 174000 | 140000 | 7.633 |

| 6321 | 321 | 105 | 225 | 49 | 182000 | 153000 | 8.677 |

| 6322 | 322 | 110 | 240 | 50 | 203000 | 180000 | 9.603 |

| 6324 | 324 | 120 | 260 | 55 | 208000 | 186000 | 12.750 |

| 6326 | 326 | 130 | 280 | 58 | 230000 | 216000 | 18.400 |

| 6328 | 328 | 140 | 300 | 62 | 251000 | 245000 | 22.000 |

| 6330 | 330 | 150 | 320 | 65 | 276000 | 285000 | 23.000 |

| 6332 | 332 | 160 | 340 | 68 | 285000 | 300000 | 29.000 |

| 6334 | 334 | 170 | 360 | 72 | 312000 | 340000 | 34.500 |

| 6336 | 336 | 180 | 380 | 75 | 351000 | 405000 | 42.500 |

| 6338 | 338 | 190 | 400 | 78 | 371000 | 430000 | 49.000 |

| 6340 | 340 | 200 | 420 | 80 | 377000 | 465000 | 55.500 |

| 6344 | 344 | 220 | 460 | 88 | 410000 | 520000 | 60.800 |

| 6348 | 348 | 240 | 500 | 95 | 470000 | 624000 | 93.300 |

| 6352 | 352 | 260 | 540 | 102 | 531000 | 741000 | 116.000 |

| 6356 | 356 | 280 | 580 | 108 | 568000 | 845000 | 145.000 |

| 6360 | 360 | 300 | 620 | 109 | 593000 | 886000 | 169.000 |

| 6364 | 364 | 320 | 670 | 112 | 634000 | 1010000 | 207.000 |

Reviews

There are no reviews yet.