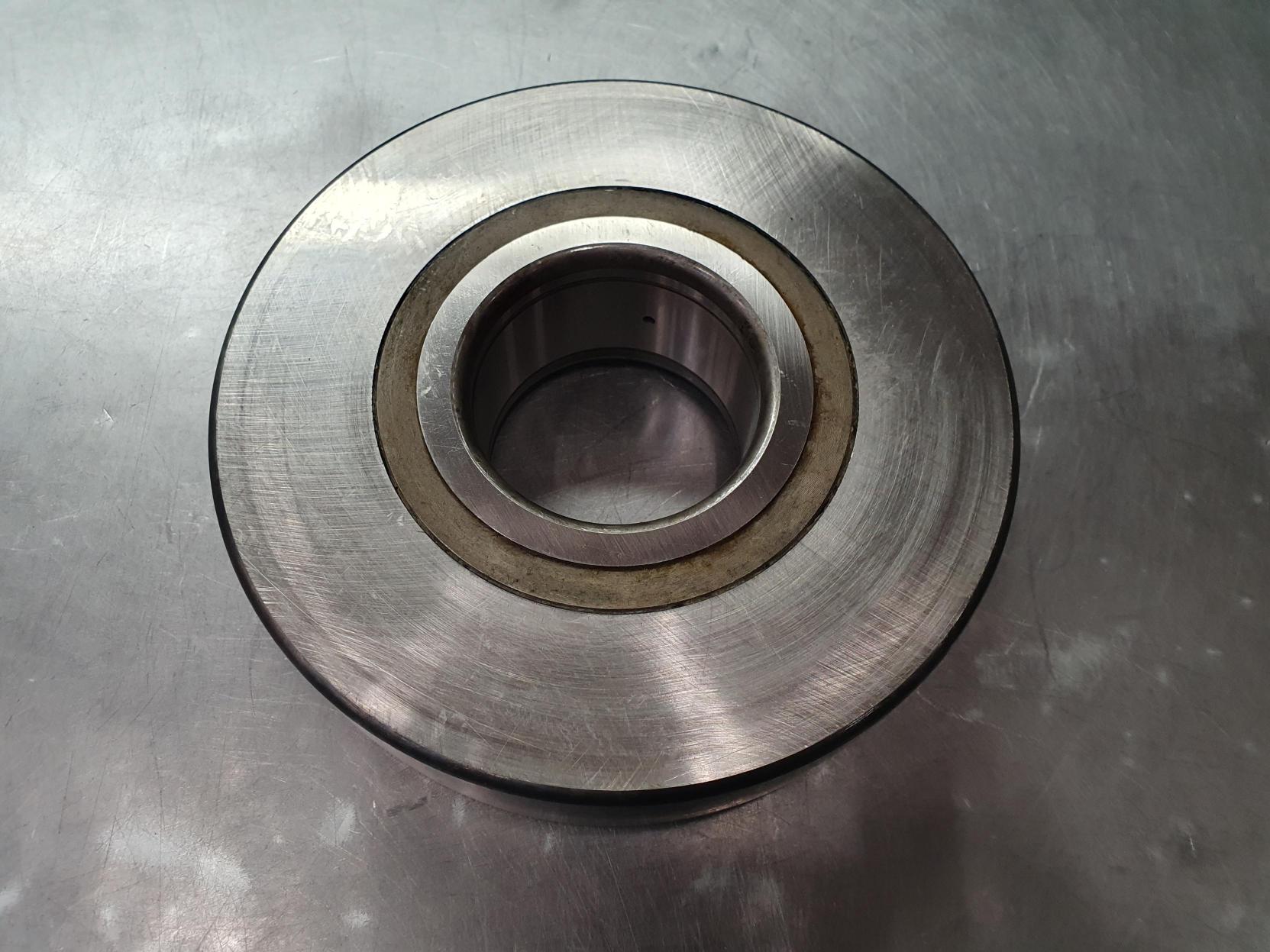

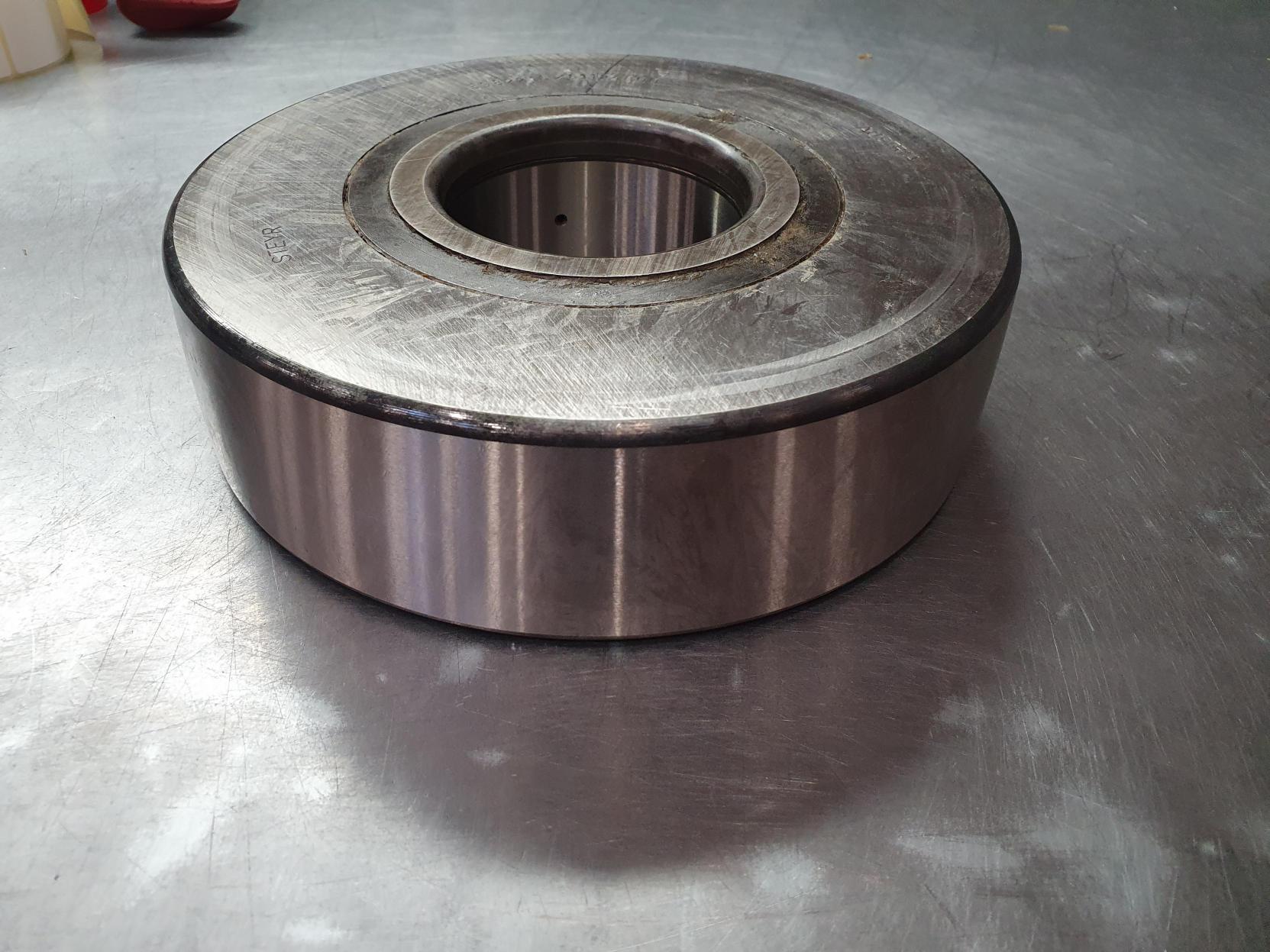

Description

Core Characteristics

High Load-Bearing Capacity:Made of high-strength bearing steel (e.g., GCr15), with outer ring and rolling elements undergoing quenching heat treatment, capable of withstanding heavy load impact during forklift lifting and handling, suitable for 1-10 ton forklift load requirements; the 5982216/61124800 model optimizes raceway curvature and contact angle, with a basic static load rating of 76.5kN, which can withstand frequent start-stop impact loads in 3-5 ton forklift drive axles.

Pollution-Resistant Sealing:Equipped with double-sided rubber seals (2RS) or metal dust covers (ZZ), effectively blocking dust, oil stains and water in the forklift working environment to prevent rust of internal parts; the 5982216/61124800 model adopts enhanced rubber seals (2RS+), with a 30% improvement in seal lip fit, providing better protection in dusty scenarios such as building material factories and mines.

Impact Resistance Toughness:Bearing cages are made of reinforced nylon or stamped steel. Under impact conditions of forklift start-stop and steering, they can prevent rolling element deviation or damage, improving operation stability; the 5982216/61124800 model uses a stamped steel cage (SPCC material), with impact strength 50% higher than that of nylon cages, suitable for forklift operations on rough sites.

Low Friction Loss:Through precision grinding, the tolerance of bearing inner and outer rings and the roundness of rolling elements are controlled. With special grease, the friction coefficient (≤0.0015) is reduced, lowering energy consumption and heat generation; the 5982216/61124800 model, due to P6-grade precision processing, has a rolling element roundness error ≤0.002mm, and the friction coefficient can be as low as 0.0012, further reducing transmission energy consumption.

Long-Life Design:Optimized contact angle and raceway curvature reduce stress concentration. Under normal maintenance, the service life can reach 8000-12000 hours, reducing customer replacement costs; the 5982216/61124800 model, due to the combination of polyurea grease and enhanced sealing, has a service life of 10000-13000 hours, 15% longer than ordinary bearings of the same type.

The Working Principle

Load Transmission:When the forklift lifts goods or travels, external loads (such as goods weight, forklift’s own weight) are transmitted from the bearing outer ring to the rolling elements (balls/rollers), then from the rolling elements to the inner ring, and finally to the forklift shafting, completing load dispersion; the 5982216/61124800, as a tapered roller bearing, its tapered rolling elements match the inner and outer ring tapered raceways, which can bear both radial and axial composite loads, achieving bidirectional load balance in the power transmission of forklift drive axles.

Friction Reduction:When rolling elements roll between the inner and outer ring raceways, only slight rolling friction (much smaller than sliding friction) is generated. With the oil film formed by grease, the wear of contact surfaces is further reduced, ensuring flexible rotation of forklift components; the pre-filled polyurea grease of 5982216/61124800 has higher oil film strength, which can maintain stable lubrication at a speed of 2200r/min, reducing direct contact wear between raceways and rolling elements.

Positioning and Guidance:The bearing inner ring is in interference fit with the forklift shaft, and the outer ring is in transition fit with the bearing housing. Through precise dimensional tolerance, the radial and axial positions of the shafting are fixed, preventing shafting deviation during forklift operation and ensuring steering and transmission accuracy; the P6-grade precision of 5982216/61124800 controls the fit clearance between the inner ring and the 80mm shaft diameter to 0.005-0.01mm, avoiding radial runout of the drive axle shafting during operation.

Sealing Protection:Seals fit closely with the inner and outer rings to form a closed space, preventing impurities from entering the raceway, while keeping grease from leaking, maintaining the internal cleanliness and lubrication state of the bearing, and extending the service life; the 2RS+ enhanced sealing structure of 5982216/61124800 can block impurity intrusion for a long time in an environment with dust concentration ≤10mg/m³, maintaining internal cleanliness.

Application Fields

Forklift Transmission System:Adapted to drive axles, gearboxes, and drive wheel shafts, supporting rotating components during power transmission, ensuring stable power output when the forklift travels, suitable for internal combustion forklifts, electric forklifts, etc.; the 5982216/61124800 model is specially designed for 3-5 ton internal combustion forklift drive axles, and has been batch-matched with Heli K30 series and Hangcha CPC35 series forklifts, showing stable performance in long-distance handling in logistics parks and factory workshops.

Forklift Steering System:Installed on steering knuckles and steering wheel shafts, bearing radial and axial loads during steering, ensuring flexible forklift turning and reducing steering resistance, suitable for counterbalanced forklifts and reach trucks.

Forklift Lifting System:Used for hydraulic cylinder piston rods, chain sprockets, and lifting drums, bearing vertical loads when lifting goods, reducing friction during lifting, ensuring stable lifting of goods, suitable for stackers and pallet trucks.

Special Working Condition Forklifts:For high-temperature workshops (e.g., metallurgical plants), humid warehouses (e.g., food processing plants), and dusty sites (e.g., building material factories), provide special forklift bearings with high temperature resistance, corrosion resistance, and enhanced sealing to ensure reliable operation in harsh environments; the 5982216/61124800 model, with a high temperature resistance upper limit of 130℃ and 2RS+ enhanced sealing, can be adapted to cement handling forklifts in building material factories and auxiliary high-temperature material forklifts in metallurgical plants, solving the problem of bearing vulnerability in dusty and high-temperature scenarios.

Reviews

There are no reviews yet.