Description

Basic Parameters

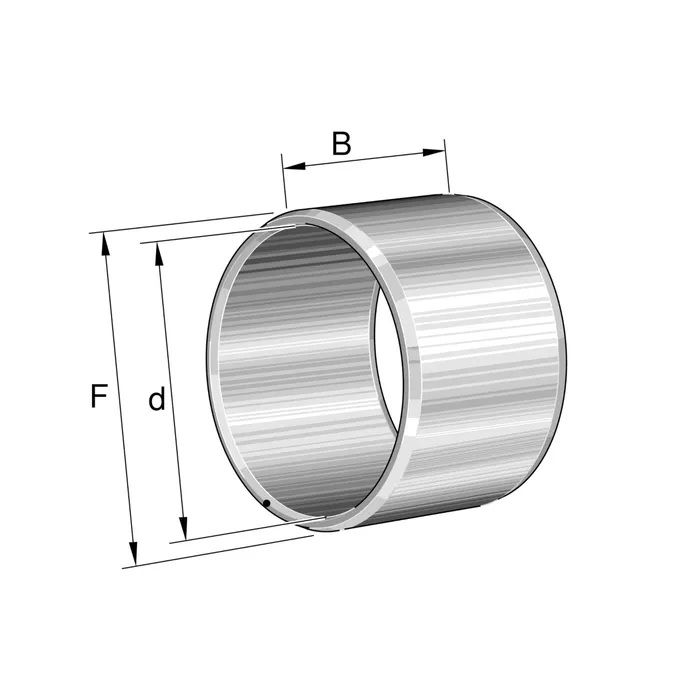

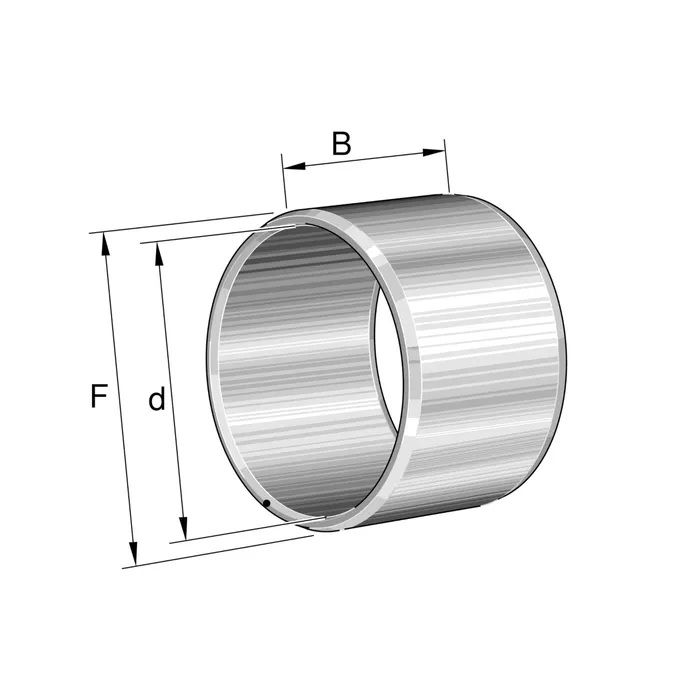

The IR series inner ring features a geometric design with an inner diameter of φ50 mm (adjustable for shaft fit, tolerance h6), an outer diameter of φ80 mm (tolerance H7 for housing compatibility), a width of 20 mm, and C1.5 mm chamfers. Constructed from bearing steel (e.g., GCr15, SUJ2) or alloy structural steel (e.g., 42CrMo), it undergoes heat treatment for a hardness of HRC 58–62 (through-hardened) or case-carburized surfaces (HRC 58–63, core HRC 30–45), with ground surfaces (Ra ≤ 0.8 μm) and anti-corrosion plating. Mechanically, it has a basic dynamic load rating (C) of 22 kN, static load rating (C0) of 15 kN, a limiting speed of 5000 RPM, and an L10 fatigue life of ≥1×10⁶ revolutions. Designed for interference/transition fits (inner bore: φ50 H7/k6; outer ring: φ80 K7/h6), it may include optional keyways (14 mm width, 6 mm depth) or M50×1.5 threads for axial fixation. Weighing ~0.8 kg, it requires lithium-based grease (-20°C–120°C) or oil lubrication and complies with ISO 492 or equivalent standards, adaptable for mechanical, automotive, or aerospace applications with potential adjustments for specific needs like tooth profiles or seal grooves.

Product Application

The IR series inner ring, a high-precision core component for mechanical transmission, leverages its optimized geometric design, superior material performance, and reliable structural strength across diverse industries—including industrial manufacturing, automotive, aerospace, and energy equipment. Engineered to adapt to complex working conditions, it provides stable support and efficient power transmission for rotating systems.

In rolling bearings (such as deep-groove ball bearings and cylindrical roller bearings), the IR series inner ring forms a precise fit with the shaft journal (inner bore tolerance h6, shaft-based fit design). Through interference or transition fits (e.g., φ50 H7/k6), it ensures radial positioning accuracy while withstanding combined radial and axial loads. Its 20mm axial width and C1.5mm chamfer design are compatible with standardized bearing housing installations, minimizing edge stress concentration. Manufactured from GCr15 bearing steel or 42CrMo alloy structural steel, it undergoes through-hardening (HRC 58–62) or case carburizing quenching (surface hardness HRC 58–63, core HRC 30–45), meeting wear and fatigue resistance requirements for high-speed rotation (limiting speed 5000 RPM). Typical applications include precision mechanical systems like reducers, conveyor drive units, and machine tool spindles.

In industrial devices such as motors, pumps, and compressors, the IR series inner ring’s outer diameter tolerance H7 (hole-based fit) enables precise clearance or interference fits with housings (e.g., φ80 K7/h6), guaranteeing concentricity and smooth rotation. Its ground surface finish (Ra ≤ 0.8 μm) reduces friction, while lubrication options—lithium-based grease (operating temperature -20°C–120°C) or oil lubrication—minimize energy consumption and temperature rise. With a basic dynamic load rating (C) of 22 kN and static load rating (C0) of 15 kN, it withstands cyclic impact loads, extending equipment maintenance intervals. For example, in industrial pumps, its anti-corrosion black oxide coating or surface plating resists erosion from coolants and lubricants, ensuring long-term reliability in wet or dusty environments.

In automotive engine camshaft and crankshaft bearings, the IR series inner ring’s lightweight design (~0.8 kg) combined with high-strength materials meets low-vibration requirements at high speeds (exceeding 5000 RPM). Optional keyways (14mm width, 6mm depth) or threads (M50×1.5) enable torque transmission with gears and pulleys, preventing slip failures. The case carburizing quenching process enhances anti-seizure performance under frequent start-stop dynamic loads, while its L10 fatigue life of ≥1×10⁶ revolutions satisfies the automotive industry’s long-life demands.

In transmissions and differentials, the inner ring’s precise tolerance control ensures gear meshing accuracy, reducing transmission noise. Its fatigue resistance effectively handles alternating loads from complex road conditions. For new energy vehicles, its low-friction surface treatment and high-speed stability are ideal for high-speed, high-efficiency electric drive systems, contributing to extended driving range.

In high-end fields like aircraft engine bearings and UAV drivelines, the IR series inner ring can be customized with lightweight alloys (e.g., high-strength titanium alloy derivatives), reducing rotational inertia while maintaining rated loads. Under extreme conditions (e.g., high temperature, high vacuum), optimized heat treatment and surface coatings (e.g., molybdenum disulfide solid lubrication films) enable operation in a wide temperature range (-50°C–200°C), ensuring stable performance in high-overload, high-reliability aerospace applications. Compliant with ISO 492 (rolling bearing tolerances) and equivalent international standards, it supports customization for tooth profiles, seal grooves, or material upgrades to meet unique industry requirements.

In wind turbines, generators, and hydraulic systems, the IR series inner ring’s robust load-bearing capacity and corrosion resistance make it suitable for heavy-duty and outdoor environments. Its compatibility with standardized interfaces simplifies integration into large-scale equipment, while the optional anti-corrosion plating protects against moisture and chemical exposure in offshore or high-humidity settings. The balance of high rigidity and low friction ensures efficient energy transfer, critical for maximizing the output of renewable energy systems.

Product List

轴径

Shaft

Diameter mm |

轴承型号

Bearing Designation |

外型尺寸

Boundary Dimensions |

| d |

F |

B |

Rs |

| mm |

min. |

| 5 |

IR — |

5 |

8 |

12 |

0.3 |

| IR — |

5 |

8 |

16 |

0.3 |

| 6 |

IR — |

6 |

9 |

12 |

0.3 |

| IR — |

6 |

9 |

16 |

0.3 |

| 口IR — |

6 |

10 |

10 |

0.3 |

| ■IR — |

6 |

10 |

12 |

0.3 |

| 7 |

IR LR |

7 |

10 |

10.5 |

0.3 |

| IR — |

7 |

10 |

12 |

0.3 |

| IR — |

7 |

10 |

16 |

0.3 |

| 8 |

口IR — |

8 |

12 |

10 |

0.3 |

| IR LR |

8 |

12 |

10.5 |

0.3 |

| ■IR — |

8 |

12 |

12 |

0.3 |

| IR LR |

8 |

12 |

12.5 |

0.3 |

| 9 |

IR — |

9 |

12 |

12 |

0.3 |

| IR — |

9 |

12 |

16 |

0.3 |

| 10 |

IR LR |

10 |

13 |

12.5 |

0.3 |

| 口IR — |

10 |

14 |

12 |

0.3 |

| IR — |

10 |

14 |

13 |

0.3 |

| ■IR — |

10 |

14 |

14 |

0.3 |

| IR — |

10 |

14 |

16 |

0.3 |

| IR — |

10 |

14 |

20 |

0.3 |

| 12 |

IR — |

12 |

15 |

12 |

0.3 |

| IR LR |

12 |

15 |

12.5 |

0.3 |

| IR — |

12 |

15 |

16 |

0.3 |

| IR LR |

12 |

15 |

16.5 |

0.3 |

| IR LR |

12 |

15 |

22.5 |

0.3 |

| 口IR — |

12 |

16 |

12 |

0.3 |

| IR — |

12 |

16 |

13 |

0.3 |

| ■IR — |

12 |

16 |

14 |

0.3 |

| IR — |

12 |

16 |

16 |

0.3 |

| IR — |

12 |

16 |

20 |

0.3 |

| IR — |

12 |

16 |

22 |

0.3 |

| 14 |

IR — |

14 |

17 |

17 |

0.3 |

Reviews

There are no reviews yet.