Description

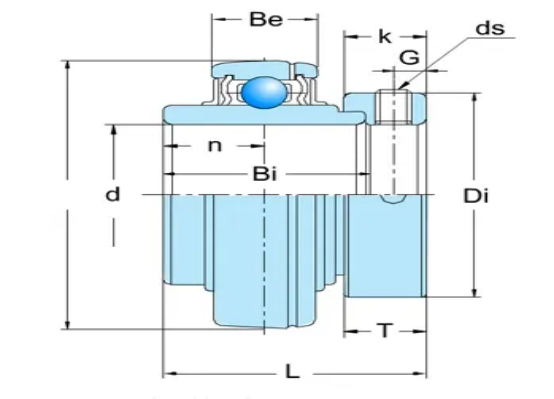

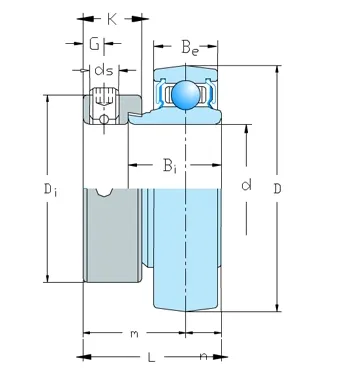

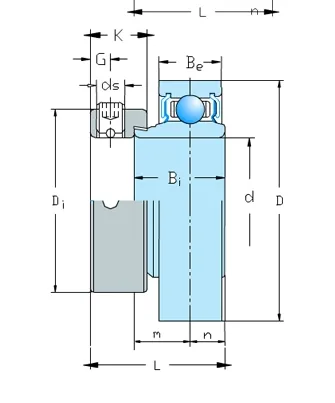

Basic Parameters

“SA” series logo

- “SA” is the name of a bearing series. SA series bearings usually have the notable characteristic of a split structure. Split bearings do not require moving the shaft or connected machine parts during installation and removal, greatly facilitating equipment maintenance operations.

“20” series type

- “20” indicates that this bearing belongs to the SA20 series. Different series will have differences in aspects such as size, structural design, and load-carrying capacity. The SA20 series has its specific size range and performance characteristics.

“6” size specification“6” corresponds to a specific size specification. In the SA20 series, “6” determines the specific size parameters of this bearing. Generally:

Inner diameter: The inner diameter of SA206 bearing is usually 30mm.

Outer diameter: Its outer diameter is generally 62mm.

Working Principle

Easy to install and disassemble

The SA206 adopts a split structure design, which is its most significant advantage. During installation, there is no need to move the shaft or other large machine parts connected to it, greatly saving installation time and labor costs. Similarly, when the equipment needs maintenance or bearing replacement, this split structure can make the operation more convenient and quick, reducing equipment downtime and improving production efficiency. For example, in some large industrial equipment that is not easy to move or disassemble, the split characteristic of SA206 can enable you to easily complete the installation and replacement operations of bearings.

Reliable carrying capacity

Although the SA206 is easy to install in structure, it is not inferior in terms of carrying capacity. This bearing can withstand a certain amount of radial load. Whether it is under the continuous radial force generated by rotating equipment or the radial load brought by some instantaneous impacts, it can maintain stable performance and ensure the normal operation of the equipment. In equipment such as small industrial motors and conveyor belt rollers, it can well withstand the radial force generated during the working process and ensure the smooth operation of the equipment.

Adapt to various working environments

The SA206 bearing has a certain degree of environmental adaptability. Under some relatively harsh working conditions, such as the presence of dust and moisture, it can reduce the erosion of external impurities to the inside of the bearing through reasonable sealing design (if relevant sealing components are equipped), and prolong the service life of the bearing. For example, in agricultural machinery applications, in the face of soil, dust and occasional moisture contact, SA206 can maintain a good working state by relying on its own structure and possible sealing protection.

Performance feature

Easily installed and disassembled

The SA206 adopts a split structure design, which is its most significant advantage. During installation, there is no need to move the shaft or other large machine parts connected to it, greatly saving installation time and labor costs. Similarly, when the equipment needs maintenance or bearing replacement, this split structure can make the operation more simple and quick, reducing equipment downtime and improving production efficiency. For example, in some large industrial equipment that is not easy to move or disassemble, the split characteristic of SA206 can enable you to easily complete the installation and replacement operations of bearings.

Reliable carrying capacity

Although the SA206 is easy to install in structure, it is not inferior in terms of carrying capacity. This bearing can withstand a certain amount of radial load. Whether it is under the continuous radial force generated by rotating equipment or the radial load brought by some instantaneous impacts, it can maintain stable performance and ensure the normal operation of the equipment. In equipment such as small industrial motors and conveyor belt rollers, it can well withstand the radial force generated during the working process and ensure the smooth operation of the equipment.

Adapt to various working environments

The SA206 bearing has a certain degree of environmental adaptability. Under some relatively harsh working conditions, such as the presence of dust and moisture, it can reduce the erosion of external impurities to the inside of the bearing through reasonable sealing design (if relevant sealing components are equipped), and prolong the service life of the bearing. For example, in agricultural machinery applications, in the face of soil, dust and occasional moisture contact, SA206 can maintain a good working state by relying on its own structure and possible sealing protection.

Product Application

Agricultural machinery

On the rotating parts of agricultural machinery such as small seeders and harvesters, SA206 is an extremely ideal choice. The working environment of agricultural machinery is complex, often accompanied by dust, mud, and a certain degree of humidity. Moreover, during the working process, its rotating parts will generate radial loads. The split structure of the SA206 bearing makes it convenient for quick maintenance and replacement in the field. At the same time, its load-bearing capacity and certain environmental adaptability can ensure the stable operation of agricultural machinery during the operating season.

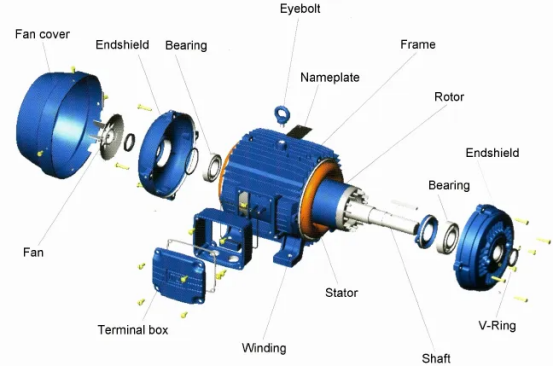

Industrial motors and conveyor belt equipment

For small industrial motors, SA206 can provide reliable support for the motor rotor and withstand the radial force generated during motor operation. In terms of supporting the rollers of conveyor belts, this bearing can adapt to the rotating working mode of the rollers and ensure the smooth operation of the conveyor belt. During equipment maintenance, its characteristic of being easy to install and disassemble can reduce equipment downtime and improve production efficiency.

Product List

| Bearing No. | Dimensions(mm inch) | Dynamic | Static | weight | |||||||||

| ISO | d | D | B2 | B1 | B | S | Bolt size | G | Bp | Dp | Cr | Cor | kg |

| SA201 | 12 | 40 | 28.6 | 19.1 | 12 | 6.5 | M6×0.75 | 4.8 | 13.5 | 28.6 | 7360 | 4480 | 0.12 |

| SA202 | 15 | 47 | 28.6 | 19.1 | 12 | 6.5 | M6×0.75 | 4.8 | 13.5 | 28.6 | 7360 | 4480 | 0.1 |

| SA203 | 17 | 47 | 28.6 | 19.1 | 12 | 6.5 | M6×0.75 | 4.8 | 13.5 | 28.6 | 7360 | 4480 | 0.09 |

| SA204 | 20 | 47 | 31 | 21.5 | 14 | 7.5 | M6×0.75 | 4.8 | 13.5 | 33.3 | 9880 | 6200 | 0.16 |

| SA205 | 25 | 52 | 31 | 21.5 | 15 | 7.5 | M6×0.75 | 4.8 | 13.5 | 38.1 | 10780 | 6980 | 0.2 |

| SA206 | 30 | 62 | 35.7 | 23.8 | 16 | 9 | M6×0.75 | 6 | 15.9 | 44.5 | 14970 | 10040 | 0.3 |

| SA207 | 35 | 72 | 38.9 | 25.4 | 17 | 9.5 | M8×1 | 6.8 | 17.5 | 55.6 | 19750 | 13670 | 0.42 |

| SA208 | 40 | 80 | 43.7 | 30.2 | 18 | 11 | M8×1 | 6.8 | 18.3 | 60.3 | 22710 | 15940 | 0.6 |

| SA209 | 45 | 85 | 43.7 | 30.2 | 19 | 11 | M8×1 | 6.8 | 18.3 | 63.5 | 24360 | 17710 | 0.76 |

| SA210 | 50 | 90 | 43.7 | 30.2 | 20 | 11 | M8×1 | 6.8 | 18.3 | 69.9 | 26980 | 19840 | 0.91 |

| SA211 | 55 | 100 | 48.4 | 32.5 | 21 | 12 | M8×1 | 8 | 20.7 | 76.2 | 33370 | 25110 | 1.26 |

| SA212 | 60 | 110 | 53.1 | 37.2 | 22 | 13.5 | M10×1 | 8 | 22.3 | 84.2 | 36740 | 27970 | 1.7 |

Reviews

There are no reviews yet.