Description

Basic Parameters

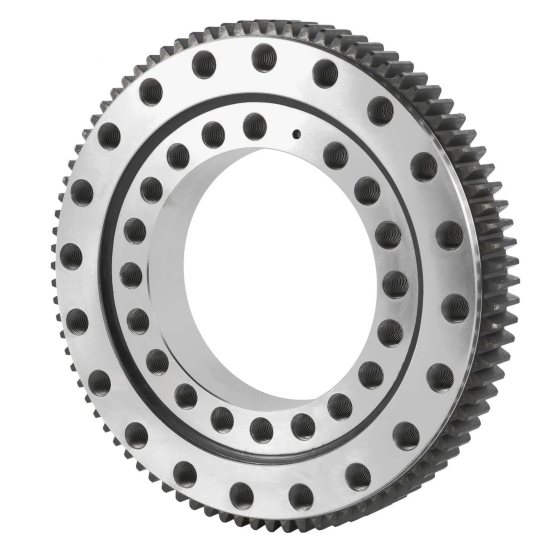

FODA’s large slewing support bearings are engineered with a wide range of specifications to meet diverse heavy-duty requirements. With outer diameters from 500 to 5000 mm and inner diameters from 300 to 4500 mm, these bearings can handle rated dynamic loads from 500 to 50,000 kN (ball type) or 1,000 to 100,000 kN (roller type), along with significant moment load capacities up to 2,000,000 N·m. Available in various structures like single-row four-point contact ball, double-row ball, single-row crossed roller, and three-row roller types, they feature 42CrMo alloy steel rings with surface quenching (HRC 58–62) and GCr15SiMn rolling elements (HRC 60–64). These bearings operate within -30°C to +120°C, offer IP65 dustproof protection as standard, and comply with ISO 9001, ISO 14001, and international industry standards. Custom configurations for dimensions, load ratings, and environmental resistance are also available to suit specific applications.

Features

– High precision: Ensure smooth and accurate operation of equipment.

– High load capacity: can withstand huge loads.

– High rigidity: ensure no deformation under heavy load.

– Compact structure: small space, easy to install.

Application field

FODA Bearing’s large slewing support bearings play a crucial role in a multitude of heavy – duty industries. In the construction sector, they are indispensable for tower cranes, enabling smooth 360 – degree rotation while supporting heavy loads during lifting operations. Mobile cranes and excavators also rely on these bearings to ensure stable and efficient movement of booms and buckets. In the wind energy industry, large slewing bearings are used in wind turbines, allowing the nacelle to rotate precisely to face the wind direction, optimizing power generation. For port machinery, such as ship – to – shore cranes and rubber – tired gantry cranes, these bearings withstand extreme loads and harsh marine environments, facilitating the rapid and reliable handling of containers. In mining equipment, slewing bearings support the massive rotating components of excavators, loaders, and stacker – reclaimers, enduring high – impact forces and abrasive conditions. Additionally, they are utilized in industrial kilns and rotary dryers in the cement and chemical industries, ensuring the smooth rotation of large – diameter drums under heavy loads and high – temperature conditions.

– Construction machinery: cranes, excavators, etc.

– Marine equipment: such as steering gear, crane, etc.

– Wind power equipment: yaw and variable pitch systems for wind turbines.

– Medical equipment: rotating parts of large medical equipment such as CT machines.

– Aerospace: Used for aircraft landing gear, satellite dishes, etc.

Reviews

There are no reviews yet.