Description

Basic Parameters

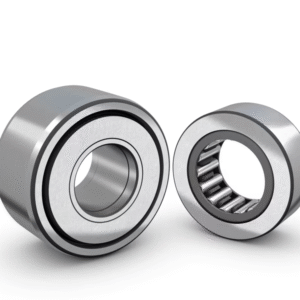

The NKI 5/12 TN is a needle roller bearing with an inner ring designed for compact radial load applications. It features a bore diameter (d) of 5 mm, an outer diameter (D) of 12 mm, and a width (B) of 5 mm, providing a space-efficient solution for limited radial spaces. The bearing incorporates a cage made of polyamide (PA) to retain the needle rollers, ensuring smooth rolling motion and reducing friction. Constructed with high-quality chrome steel for both the inner ring and needle rollers, it offers reliable performance under moderate to heavy radial loads. The dynamic radial load rating (C) is approximately 3.85 kN, while the static radial load rating (C₀) stands at 4.75 kN, making it suitable for applications requiring consistent load-carrying capacity. With a maximum operating speed of 18,000 rpm under well-lubricated conditions, this bearing adheres to standard dimensional and tolerance specifications (ISO 1628-1) for interchangeability. Its design prioritizes high rigidity and low rotational torque, making it ideal for use in machinery, power tools, and precision equipment where space constraints and radial load performance are critical factors.

Product Application

The NKI 5/12 TN needle roller bearing excels in industrial machinery requiring compact radial load solutions with high precision. It is commonly integrated into gearboxes, conveyor systems, and small-scale transmission units where space efficiency is critical. For example, in automated assembly lines, its 5mm bore diameter and 12mm outer diameter allow seamless installation in tight mechanical linkages, minimizing housing size without compromising load capacity. The bearing’s polyamide cage ensures stable needle roller alignment, reducing vibration and noise in high-speed conveying mechanisms. Its robust chrome steel construction withstands moderate to heavy radial loads (3.85 kN dynamic, 4.75 kN static), making it ideal for machinery operating under intermittent or fluctuating load conditions, such as packaging equipment or small-scale manufacturing tools.

In the design of electric drills, screwdrivers, and rotary tools, the NKI 5/12 TN addresses the challenge of balancing high-speed performance with compact dimensions. The bearing’s 18,000 rpm maximum speed suits motor shafts in cordless power tools, where lightweight design and efficient energy transfer are essential. The low rotational torque enabled by its precision-ground needle rollers reduces power loss, extending battery life in portable devices. Additionally, its resistance to radial misalignment supports the oscillating or rotating components in angle grinders and sanders, enhancing tool stability during aggressive material removal tasks. The bearing’s ISO-compliant tolerances ensure interchangeability with standard tooling components, streamlining maintenance and repair processes for manufacturers and end-users.

Within automotive subsystems, this bearing finds use in steering linkages, window regulators, and transmission auxiliaries. In electric vehicles (EVs), it is integrated into compact drive units and wheel hub mechanisms, where space-saving designs are critical for battery integration. The bearing’s high rigidity minimizes deflection in suspension pivot points, improving handling precision and reducing wear on adjacent components. For internal combustion engines, it supports fuel injection pump assemblies, enduring the high-frequency vibrations and temperature fluctuations typical of engine compartments. The corrosion-resistant properties of its chrome steel components also make it suitable for undercarriage applications exposed to moisture and road debris, ensuring long service life in harsh automotive environments.

In scientific and optical equipment, such as microscopes, telescopes, and measurement devices, the NKI 5/12 TN delivers the smooth, backlash-free motion required for accurate positioning. Its low friction characteristics are vital for rotating stages in coordinate measuring machines (CMMs), where minimal torque ensures precise angular adjustments. The bearing’s tight dimensional tolerances (compliant with ISO 1628-1) make it a preferred choice for optical lens turrets, enabling seamless switching between magnification levels without positional errors. In medical devices like syringe pumps or robotic surgical arms, its compact size and high load capacity support delicate movements while maintaining stability during critical operations, demonstrating versatility in precision-critical applications.

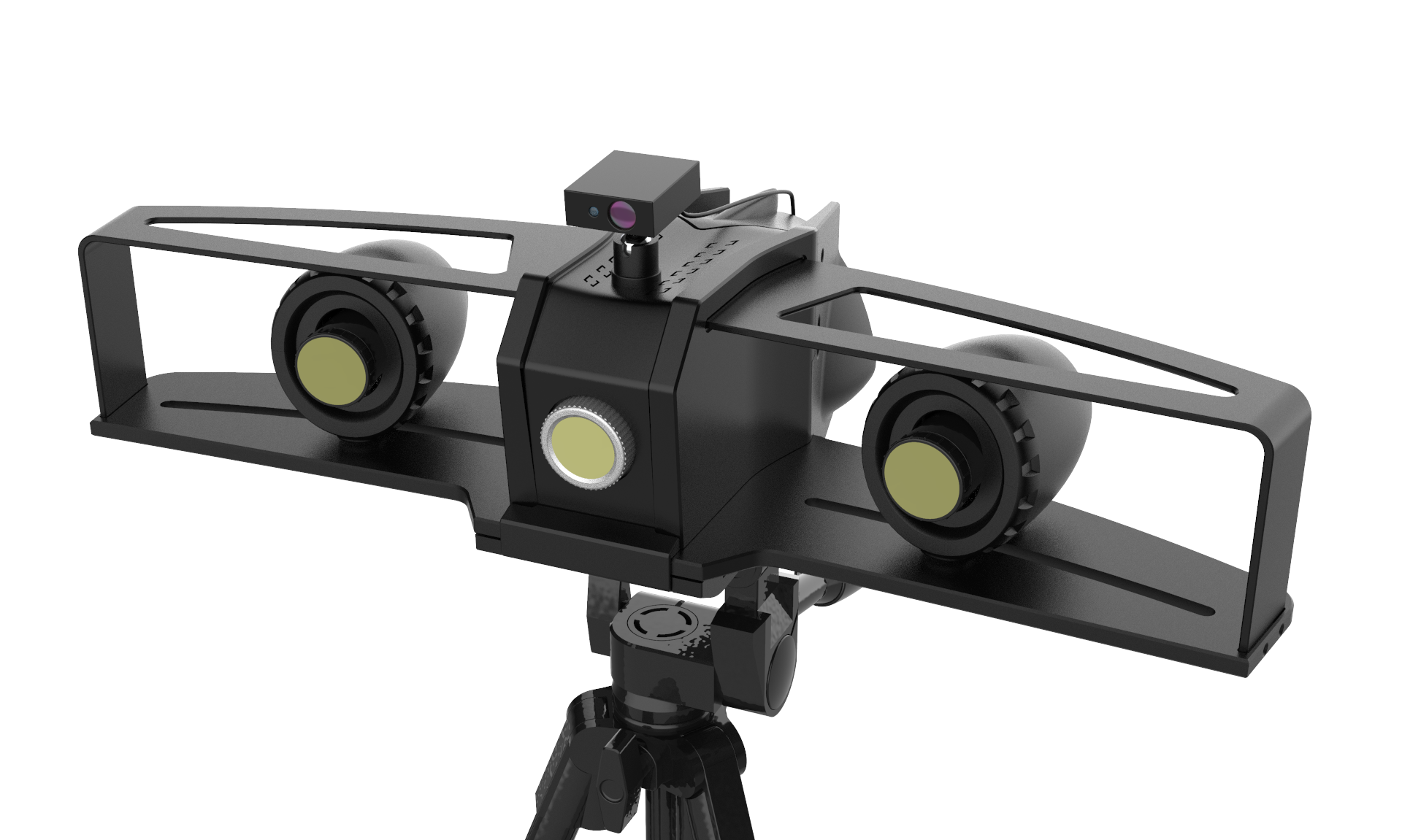

For unmanned aerial vehicles (UAVs) and aircraft subsystems, the NKI 5/12 TN balances lightweight design with robust performance. It is used in drone motor mounts, where its 5mm bore fits directly onto brushless motor shafts, reducing overall payload weight without sacrificing radial load capacity during rapid acceleration or maneuvering. In aerospace ground support equipment, such as baggage conveyor systems or aircraft door hinges, the bearing’s resistance to fatigue and high-speed operation ensures reliable performance in mission-critical applications. The material compatibility with aviation-grade lubricants further enhances its suitability for high-altitude or extreme-temperature environments, where standard bearings might fail due to lubricant degradation or dimensional instability.

Beyond standardized applications, the NKI 5/12 TN serves as a versatile component in custom machinery and prototype designs. Its modular design allows engineers to incorporate it into specialized robotic joints, automation modules, or research equipment where space constraints and load requirements demand a balance of precision and durability. The availability of a built-in inner ring eliminates the need for additional shaft machining, reducing design complexity and production costs for low-volume or bespoke projects. Whether used in agricultural sensors, marine instrumentation, or consumer electronics, the bearing’s combination of compact dimensions, high-speed capability, and reliable load performance makes it a foundational element in mechanical systems that prioritize efficiency and reliability.

Product List

轴径

Shaft

Diameter |

轴承型号

Bearing Designation |

外型尺寸

Boundary Dimensions |

基本额定负荷

Basic Load Ratings |

极限转速

Limiting

Speed |

| d |

F |

D |

B |

rs |

动

C |

静

Co |

油 润滑

Oil |

| mm |

mm |

min. |

N |

rpm |

| 5 |

+NKI5/12 TN |

5 |

8 |

15 |

12 |

0.3 |

3950 |

4100 |

32000 |

| +NKI5/16TN |

5 |

8 |

15 |

16 |

0.3 |

5100 |

5800 |

32000 |

| 6 |

+NKI6/12 TN |

6 |

9 |

16 |

12 |

0.3 |

4500 |

5000 |

31000 |

| +NKI6/16TN |

6 |

9 |

16 |

16 |

0.3 |

5900 |

7100 |

31000 |

| +NKIS6TN |

6 |

10 |

19 |

13 |

0.3 |

5800 |

6000 |

29000 |

| 7 |

+NKI7/12 TN |

7 |

10 |

17 |

12 |

0.3 |

4750 |

5500 |

29000 |

| +NKI7/16TN |

7 |

10 |

17 |

16 |

0.3 |

6200 |

7800 |

29000 |

| +NKIS7TN |

7 |

12 |

22 |

16 |

0.6 |

9600 |

10400 |

26000 |

| 8 |

NKIS 8 |

8 |

14 |

25 |

16 |

0.6 |

14400 |

13800 |

24000 |

| 9 |

NKI9/12 |

9 |

12 |

19 |

12 |

0.3 |

6400 |

7100 |

27000 |

| NKI9/16 |

9 |

12 |

19 |

16 |

0.3 |

9000 |

11000 |

27000 |

| NKIS 9 |

9 |

15 |

26 |

16 |

0.6 |

14400 |

14000 |

23000 |

| 10 |

NKI 10/16 |

10 |

14 |

22 |

16 |

0.3 |

10100 |

11500 |

25000 |

| NKI 10/20 |

10 |

14 |

22 |

20 |

0.3 |

12800 |

15600 |

25000 |

| INKIS 10 |

10 |

16 |

28 |

16 |

0.6 |

15700 |

15800 |

22000 |

| NA 4900 |

10 |

14 |

22 |

13 |

0.3 |

8500 |

9200 |

25000 |

| 12 |

NKI 12/16 |

12 |

16 |

24 |

16 |

0.3 |

11300 |

13900 |

23000 |

| NKI 12/20 |

12 |

16 |

24 |

20 |

0.3 |

14400 |

18800 |

23000 |

| INKIS 12 |

12 |

18 |

30 |

16 |

0.6 |

16800 |

17700 |

21000 |

| NA 4901 |

12 |

16 |

24 |

13 |

0.3 |

9400 |

10900 |

23000 |

| NA 6901 |

12 |

16 |

24 |

22 |

0.3 |

16000 |

21600 |

23000 |

| 15 |

NKI 15/16 |

15 |

19 |

27 |

16 |

0.3 |

13000 |

17400 |

22000 |

| NKI 15/20 |

15 |

19 |

27 |

20 |

0.3 |

16500 |

23600 |

22000 |

| INKIS 15 |

15 |

22 |

35 |

20 |

0.6 |

24500 |

28000 |

18000 |

| NA 4902 |

15 |

20 |

28 |

13 |

0.3 |

10600 |

13600 |

21000 |

| NA 6902 |

15 |

20 |

28 |

23 |

0.3 |

17300 |

25500 |

21000 |

| 17 |

NKI 17/16 |

17 |

21 |

29 |

16 |

0.3

0.3 |

13500 |

18700 |

21000 |

| NKI 17/20 |

17 |

21 |

29 |

20 |

0.3 |

17100 |

25500 |

21000 |

| NKIS 17 |

17 |

24 |

37 |

20 |

0.6 |

26000 |

31000 |

17000 |

| NA 4903 |

17 |

22 |

30 |

13 |

0.3 |

11000 |

14600 |

20000 |

| NA 6903 |

17 |

22 |

30 |

23 |

0.3 |

18600 |

29000 |

20000 |

TN=塑料保险架,允许运转温度:120℃连续地,150℃临时地,180℃短时地,)对于脂润滑,允许值为表列数值的60%。+有档圈,无润滑油孔和槽,如需要油孔和槽时,需在轴承代号上增加ASR1。

TN=plastic retainer, permissible operational temperature 120’℃,150’C for temporary use,180’℃ for short time only ‘for grease lub, the permissible value should be 60%of those in the list

*with retaining ring, no lubricating holes or grooves, please add ASR1 before the bearing code if oil holes or grooves are needed for your products. |

Reviews

There are no reviews yet.