Description

Basic Parameters

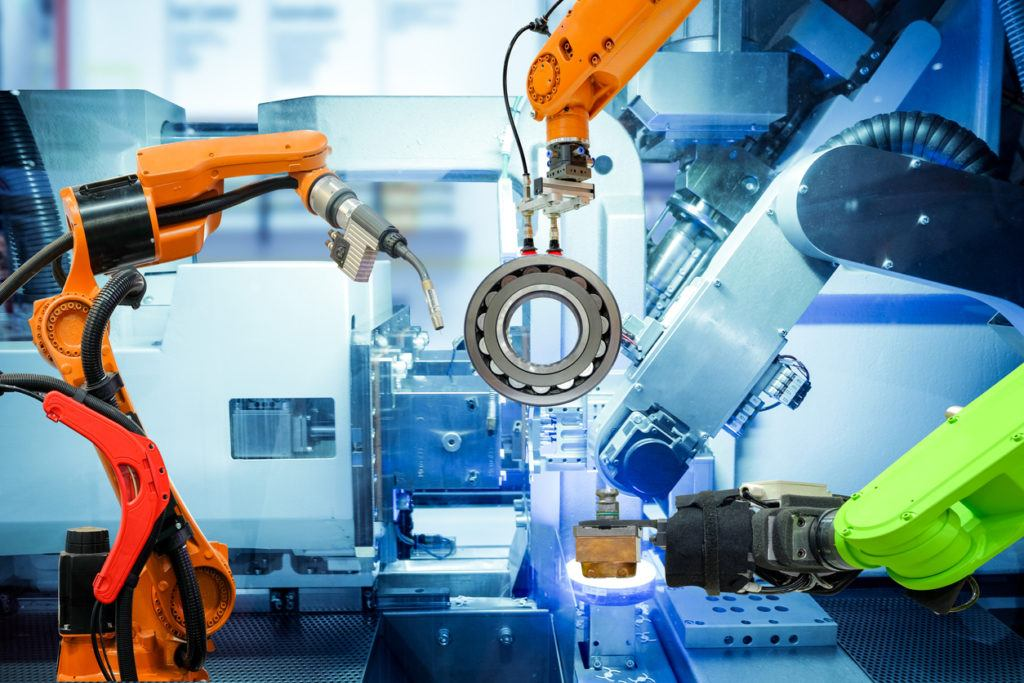

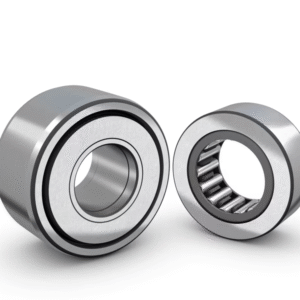

The +NK 5/10 TN is a needle roller bearing without an inner ring, designed for applications where space is limited and the shaft itself serves as the raceway. This bearing features a bore diameter of 5 mm, an outer diameter of 10 mm, and a width of 5 mm, with a compact design that utilizes cylindrical needle rollers guided by a TN-type cage, typically made of polyamide for lightweight and durable operation. Constructed with a outer ring made from high-quality bearing steel for excellent wear resistance, the bearing has a rated dynamic load capacity (C₁₀) of approximately 1.8 kN and a rated static load capacity (C₀₁₀) of around 2.5 kN, suitable for moderate radial loads. The limiting speed under well-lubricated conditions is up to 15,000 rpm, making it suitable for high-speed applications. Its inner ring-less structure allows direct contact between the rollers and the hardened shaft surface, reducing overall cross-sectional dimensions while maintaining reliable performance in machinery such as gearboxes, pumps, and transmission systems where space efficiency and radial load handling are critical.

Product Application

In compact transmission structures of industrial machinery, the +NK 5/10 TN bearing demonstrates unique advantages through its inner-ring-less design. With a super-compact size of 5mm inner diameter and 10mm outer diameter, it is suitable for space-constrained scenarios such as gearbox speed increasers and servo motor output shaft connections. The bearing uses a TN-type polyamide cage to guide cylindrical needle rollers, ensuring uniform distribution of rolling elements at high speeds (up to 15,000 rpm) and reducing frictional heat generation. This makes it ideal for precision transmission in automated production lines and printing machine drum support structures. The design of using the shaft surface directly as the raceway requires the mating shaft diameter to be quenched (hardness ≥ HRC58), enabling a 20% radial space saving compared to traditional bearings with inner rings while achieving the same load capacity.

In the trend of automotive miniaturization, this bearing is widely used in worm shaft supports of electric power steering systems (EPS), automatic transmission shifting mechanisms, and high-pressure fuel pump bearings in engines. Take the steering system as an example: the bearing must withstand alternating radial loads (rated dynamic load 1.8 kN) during steering operations. The combination of its lightweight polyamide cage and steel outer ring not only meets the wide-temperature working environment of -40°C to 120°C but also reduces component weight (only 1.2g per bearing) through the inner-ring-less structure, aligning with the automotive industry’s demand for weight reduction and energy efficiency. In high-speed fuel pump operations, the 15,000 rpm limiting speed ensures stable fuel delivery, avoiding wear issues caused by inner ring slippage in traditional bearings.

In the miniaturization design of precision instruments, such as optical lens focusing mechanisms and rotating joints of portable detection equipment, the high precision (ISO tolerance grade IT9) and low friction (starting torque ≤ 0.3N·m) of the +NK 5/10 TN bearing play a key role. The precise grinding of its outer ring raceway (surface roughness Ra ≤ 0.2μm) ensures smooth rotational movement, suitable for equipment requiring sub-micron positioning accuracy. In the consumer electronics field, it can be applied to high-end drone motor shafts and hinge structures of foldable screens. The inner-ring-less design simplifies the assembly process by directly press-fitting the bearing onto a hardened stainless steel shaft, reducing the number of components and enhancing product reliability.

In impeller shaft supports of micro water pumps and vacuum pumps, the bearing faces potential corrosion risks from liquid media (requiring anti-rust grease) and radial load fluctuations. The steel outer ring of the +NK 5/10 TN, surface-hardened (hardness ≥ HRC62), exhibits excellent wear resistance and can withstand impact loads during pump startup (static load 2.5 kN). Its ultra-thin design with a width of 5mm allows axial space optimization in narrow pump cavities, making it particularly suitable for volume-sensitive applications such as household water purifier booster pumps and medical infusion pumps. The bearing’s open structure (non-sealed design) allows users to select appropriate sealing solutions according to working conditions, enhancing application flexibility.

For special working conditions, such as industrial robot joints in low-temperature environments or conveyor equipment idlers in high-dust environments, this bearing can expand its application boundaries through customized lubrication solutions (e.g., high-temperature lithium-based grease or low-temperature synthetic oil). The inner-ring-less structure allows users to achieve precise matching according to actual shaft diameter tolerances (recommended shaft tolerance m5), avoiding interference fit errors between traditional bearing inner rings and shafts, which is especially suitable for rapid assembly of small-batch customized equipment. In high-speed rotating platforms of experimental equipment, the bearing’s low inertia (moment of inertia ≤ 0.05g·cm²) helps improve system dynamic response performance, meeting research-grade precision requirements.

Product List

轴径

Shaft

Diameter |

轴承型号

Bearing Designation |

外型尺寸

Boundary Dimensions |

基本额定负荷

Basic Load Ratings |

极限转速

Limiting

Speed |

| Fw |

D |

c |

rs |

动

C |

静

Co |

油润滑

Oil |

| mm |

mm |

min. |

N |

rpm |

| 5 |

+NK 5/10 TN |

5 |

10 |

10 |

0.15 |

2350 |

1920 |

39000 |

| +NK 5/12 TN |

5 |

10 |

12 |

0.15 |

3000 |

2650 |

39000 |

| 6 |

+NK 6/10 TN |

6 |

12 |

10 |

0.15 |

2600 |

2280 |

37000 |

| +NK 6/12 TN |

6 |

12 |

12 |

0.15 |

3350 |

3150 |

37000 |

| 7 |

+NK 7/10 TN |

7 |

14 |

10 |

0.3 |

2850 |

2650 |

34000 |

| +NK 7/12 TN |

7 |

14 |

12 |

0.3 |

3650 |

3600 |

34000 |

| 8 |

+NK 8/12 TN |

8 |

15 |

12 |

0.3 |

3950 |

4100 |

32000 |

| +NK 8/16 TN |

8 |

15 |

16 |

0.3 |

5100 |

5800 |

32000 |

| +NKS 8 TN |

8 |

16 |

13 |

0.3 |

5000 |

4700 |

32000 |

| 9 |

+NK 9/12 TN |

9 |

16 |

12 |

0.3 |

4500 |

5000 |

31000 |

| +NK 9/16 TN |

9 |

16 |

16 |

0.3 |

5900 |

7100 |

31000 |

| 10 |

+NK 10/12 TN |

10 |

17 |

12 |

0.3 |

4750 |

5500 |

29000 |

| +NK 10/16 TN |

10 |

17 |

16 |

0.3 |

6200 |

7800 |

29000 |

| +NKS 10 TN |

10 |

19 |

13 |

0.3 |

5800 |

6000 |

29000 |

| 12 |

NK 12/12 |

12 |

19 |

12 |

0.3 |

6400 |

7100 |

27000 |

| NK 12/16 |

12 |

19 |

16 |

0.3 |

9000 |

11000 |

27000 |

| +NKS 12 TN |

12 |

22 |

16 |

0.6 |

9600 |

10400 |

26000 |

| 14 |

NK 14/16 |

14 |

22 |

16 |

0.3 |

10100 |

11500 |

25000 |

| NK 14/20 |

14 |

22 |

20 |

0.3 |

12800 |

15600 |

25000 |

| +NKS 14 |

14 |

25 |

16 |

0.6 |

14400 |

13800 |

24000 |

| RNA 4900 |

14 |

22 |

13 |

0.3 |

8500 |

9200 |

25000 |

| 15 |

NK 15/16 |

15 |

23 |

16 |

0.3 |

10700 |

12700 |

24000 |

| NK 15/20 |

15 |

23 |

20 |

0.3 |

13600 |

17200 |

24000 |

| +NKS 15 |

15 |

26 |

16 |

0.6 |

14400 |

14000 |

23000 |

| 16 |

NK 16/16 |

16 |

24 |

16 |

0.3 |

11300 |

13900 |

23000 |

| NK 16/20 |

16 |

24 |

20 |

0.3 |

14400 |

18800 |

23000 |

| +NKS 16 |

16 |

28 |

16 |

0.6 |

15700 |

15800 |

22000 |

| RNA 4901 |

16 |

24 |

13 |

0.3 |

9400 |

10900 |

23000 |

| RNA 6901 |

16 |

24 |

22 |

0.3 |

16000 |

21600 |

23000 |

| 17 |

NK 17/16 |

17 |

25 |

16 |

0.3 |

11900 |

15000 |

23000 |

| NK 17/20 |

17 |

25 |

20 |

0.3 |

15100 |

20400 |

23000 |

| 18 |

NK 18/16 |

18 |

26 |

16 |

0.3 |

12500 |

16200 |

22000 |

| NK 18/20 |

18 |

26 |

20 |

0.3 |

15800 |

22000 |

22000 |

| +NKS 18 |

18 |

30 |

16 |

0.6 |

16800 |

17700 |

21000 |

| 19 |

NK 19/16 |

19 |

27 |

16 |

0.3 |

13000 |

17400 |

22000 |

| NK 19/20 |

19 |

27 |

20 |

0.3 |

16500 |

23600 |

22000 |

□TN=塑料保险架,

允许运转温度,120°℃连续地,150℃临时地,180°℃短时地。’)对于脂润滑,允许值为表列数值的60%。+有档圈,无润滑油孔和槽,如需要油孔和槽时,需在轴承代号上增加ASR1。

TN=plastic retainer, permissible operational temperature 120’℃,150’C for temporary use,180’c for short time only ‘lor grease lub, the permissible value should be 60% of those in the listwith retaining ring, no lubricating holes or grooves, please add ASR1 before the bearing code if oil holes or grooves are needed for your products. |

Reviews

There are no reviews yet.