Description

Basic Information

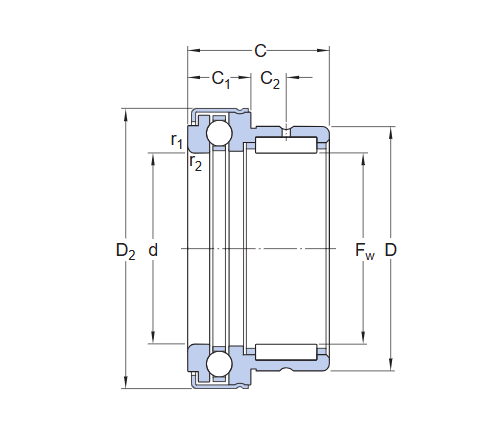

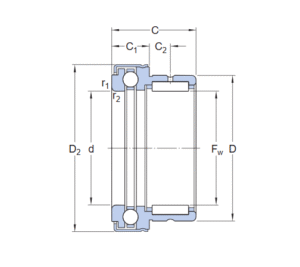

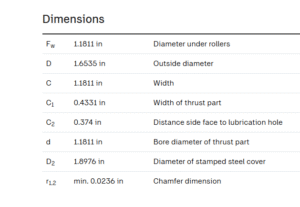

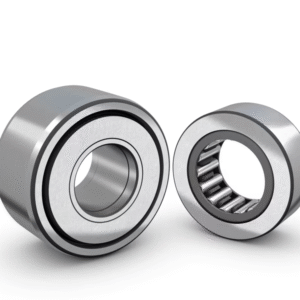

Model Meaning:In NKX30Z, “NK” represents a needle roller bearing with a cage, “X” indicates that the bearing outer ring has a rib structure, “30” refers to the inner diameter of the bearing being 30mm, and “Z” means the bearing is equipped with a stamped steel shield on one side.

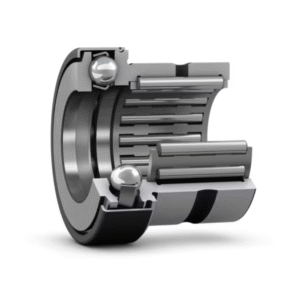

Material Composition:The bearing outer ring and needle roller are made of high-purity SUJ2 bearing steel, which has excellent wear resistance, pressure resistance and fatigue resistance; the cage is made of reinforced polyamide 66 (PA66+GF) material, which has good strength, toughness and corrosion resistance; the shield is a high-quality stamped steel plate, and its surface is treated with anti-rust, which can effectively prevent impurities from entering.

Accuracy Class:Complies with ISO Class 4 accuracy standard, with high rotation accuracy and stable operation, which can reduce vibration and noise during equipment operation.

Product Advantage

Compact Structure, Space-saving:Compared with traditional deep groove ball bearings, under the same inner diameter and load-bearing capacity, the NKX30Z needle roller bearing has a smaller outer diameter and thinner width, which can greatly save the internal installation space of the equipment, especially suitable for mechanical equipment with compact structure.

High Load-bearing Capacity:Adopting the design of densely arranged needle rollers, the contact area between the needle rollers and the inner and outer rings is large, which can effectively disperse the load, realize high load-bearing capacity under small radial dimensions, and prolong the service life of the equipment.

Low Friction Coefficient, High Efficiency and Energy-saving:The internal part of the bearing adopts an optimized contact structure, combined with high-quality grease, the friction coefficient is as low as below 0.0015, which can reduce energy loss during equipment operation, improve equipment operation efficiency and reduce energy consumption costs.

Good Sealing Performance:The one-side stamped steel shield (Z-type) design can effectively prevent dust, impurities, moisture, etc. from entering the bearing, and at the same time prevent the leakage of grease, reduce the frequency of bearing maintenance, and adapt to harsh working environments such as dust and humidity.

Excellent Fatigue Resistance:The bearing steel undergoes a strict heat treatment process, with uniform grain refinement. Coupled with the precise processing technology, the bearing has excellent fatigue resistance. It can still maintain stable performance and is not prone to early failure under long-term high-frequency operation conditions.

Product Application

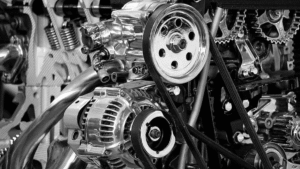

Automotive Industry:It can be used in the shifting mechanism of the automobile transmission gearbox, the clutch release bearing assembly, the drive axle differential and other parts. It can bear the radial load during the operation of the transmission and differential, and ensure the stable operation of the transmission system.

Industrial Machinery Equipment:Suitable for the auxiliary support of the machine tool spindle, the roller bearing of the conveying machinery, the transmission roller assembly of the printing machinery, etc. The high rotation accuracy and low friction characteristics can ensure the processing accuracy and conveying efficiency of the equipment.

Power Tools Field:It can be applied to the gearbox of the impact drill, the transmission mechanism of the angle grinder, etc. The compact structure can adapt to the small body design of the power tools, and the high load-bearing capacity and fatigue resistance can meet the high-frequency and high-load working requirements of the power tools.

Household Appliance Industry:Used in the dewatering bucket bearing assembly of the washing machine, the auxiliary support bearing of the air conditioner compressor, etc. The good sealing performance can prevent moisture and impurities from entering, and ensure the long-term stable operation of household appliances.

Reviews

There are no reviews yet.