Description

Basic Parameters

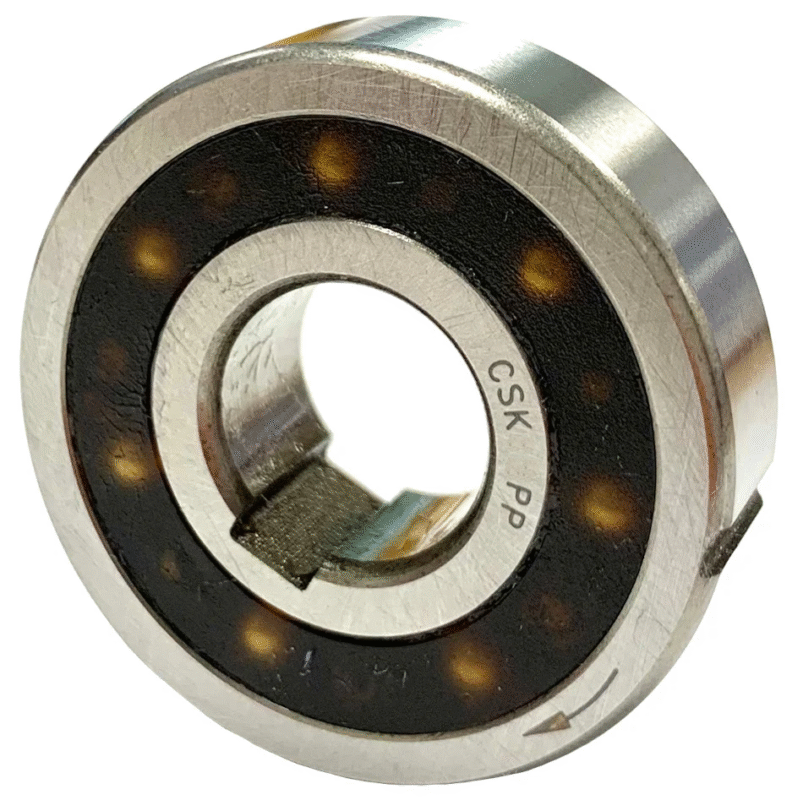

The CSK17PP one-way bearing, a key component for directional motion control, features a compact design with an inner diameter of 17 mm, an outer diameter of 40 mm, and a width of 12 mm, weighing approximately 0.075 kg. Engineered for reliable performance, it has a dynamic load rating of 15.2 kN and a static load rating of 10.8 kN, enabling it to handle moderate to heavy axial loads in one direction while preventing reverse rotation. The bearing operates at a maximum rotational speed of 8,000 RPM under normal lubrication conditions, utilizing a durable steel cage to retain its precision-machined rollers. Constructed from high-carbon chromium bearing steel for enhanced hardness and wear resistance, it comes in an open configuration (without seals) for easy maintenance and compatibility with various lubrication systems. Ideal for applications requiring unidirectional torque transmission, such as conveyor systems, automotive starters, and power tools, the CSK17PP balances compact size with robust load-carrying capacity, ensuring stable operation and long service life in diverse mechanical setups.

Product Application

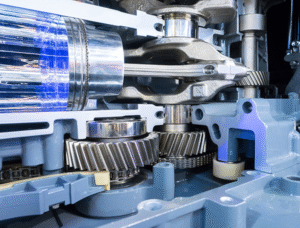

The CSK17PP one-way bearing excels in industrial mechanical transmission setups, particularly in devices requiring unidirectional torque transfer while blocking reverse motion. It is commonly integrated into gearboxes, reducers, and clutch mechanisms, where it ensures smooth power transmission in one direction to prevent backdriving and potential damage from unintended reverse loads. For example, in conveyor belt drives, the bearing maintains continuous forward motion of the belt, even when the motor temporarily stops, eliminating the risk of belt slippage or backward movement that could disrupt material handling processes. Its compact dimensions (17mm ID, 40mm OD, 12mm width) allow seamless installation in space-constrained mechanical assemblies, making it an ideal choice for retrofitting existing equipment or designing new compact transmission systems.

In the automotive sector, the CSK17PP plays a critical role in starter motors, where it enables the one-way engagement between the starter gear and the engine flywheel. During engine cranking, the bearing allows the starter to drive the flywheel in the correct rotational direction, but immediately disengages once the engine starts, preventing the flywheel from overspeeding the starter motor and causing mechanical damage. Additionally, it is used in auxiliary engine components such as alternator decouplers and timing belt tensioners, where it mitigates torsional vibrations and ensures unidirectional rotational stability under varying engine loads. The bearing’s high dynamic load rating (15.2 kN) and resistance to shock loads make it suitable for the harsh operating conditions of automotive environments, including temperature fluctuations and high-frequency vibrations.

Cordless drills, impact wrenches, and other power tools rely on the CSK17PP to achieve efficient unidirectional power transfer while protecting the motor from reverse torque during sudden jams or overloads. In these applications, the bearing allows the tool’s chuck or output shaft to rotate freely in the forward direction for drilling or tightening, but locks instantly when reverse force is applied, safeguarding the internal gear train and motor from excessive stress. Its lightweight design (0.075 kg) and high-speed capability (up to 8,000 RPM) are essential for maintaining tool portability and performance, even in high-torque, high-speed operations. The open configuration of the bearing also facilitates easy lubrication, a key requirement for portable tools that may be used in dusty or abrasive environments where regular maintenance is necessary to extend service life.

In bulk material handling systems, such as belt conveyors, roller conveyors, and bucket elevators, the CSK17PP is used to prevent backflow of materials when the conveyor stops or experiences a power outage. For instance, in inclined conveyors, the bearing ensures that the conveyor belt or rollers do not reverse under the weight of the material, avoiding costly spillage and downtime. It is also integrated into pallet handling systems and sorting machinery, where precise directional control is critical for automated material transfer. The bearing’s robust construction with high-carbon chromium steel provides excellent wear resistance against the repetitive loading and heavy axial forces typical in conveyor applications, ensuring long-term reliability without frequent replacement.

In small-scale wind turbines and solar tracking systems, the CSK17PP enables unidirectional rotation of the rotor or solar panel mount while resisting reverse motion caused by gusts or unexpected mechanical forces. For wind turbines, it acts as a backstop bearing in the gearbox, preventing the turbine from spinning backward during maintenance or when the generator is disconnected, which protects the gear teeth from impact damage. In solar trackers, the bearing ensures that the panels move smoothly to follow the sun’s trajectory but remain stationary in high winds, avoiding excessive stress on the tracking mechanism. Its ability to handle moderate static loads (10.8 kN) and operate efficiently in outdoor environments with minimal lubrication makes it a reliable component for renewable energy applications where durability and low maintenance are paramount.

In textile looms, knitting machines, and printing presses, the CSK17PP is used in feed rollers, take-up mechanisms, and tension control systems to maintain precise unidirectional motion of fabrics, paper, or other substrates. It prevents backtracking of the material during stop-start operations, ensuring consistent tension and alignment to avoid defects in the final product. For example, in printing presses, the bearing ensures that the paper feed roller moves in one direction only, preventing misfeeds or double sheets that could lead to printing errors. The bearing’s low friction design and high rotational accuracy contribute to the smooth operation of these precision machines, where even minor inconsistencies in motion can affect product quality.

Product List

| Bearing No. |

|

Dimensions(mm) |

|

torque |

Weight |

|

|

d |

D |

B |

(N.m) |

(KG) |

| CSK8 |

CSK 8P |

CSK 8PP |

8 |

22 |

9 |

2.5 |

0.015 |

| CSK12 |

CSK 12P |

CSK 12PP |

12 |

32 |

10 |

7.5 |

0.04 |

| CSK15 |

CSK 15P |

CSK 15PP |

15 |

35 |

11 |

13.5 |

0.05 |

| CSK17 |

CSK 17P |

CSK 17PP |

17 |

40 |

12 |

24.5 |

0.07 |

| CSK20 |

CSK 20P |

CSK 20PP |

20 |

47 |

14 |

40 |

0.11 |

| CSK25 |

CSK 25P |

CSK 25PP |

25 |

52 |

15 |

68 |

0.14 |

| CSK30 |

CSK 30P |

CSK 30PP |

30 |

62 |

16 |

110 |

0.21 |

| CSK35 |

CSK 35P |

CSK 35PP |

35 |

72 |

17 |

140 |

0.3 |

| CSK40 |

CSK 40P |

CSK 40PP |

40 |

80 |

22 |

260 |

0.5 |

Reviews

There are no reviews yet.