Description

Basic Parameters

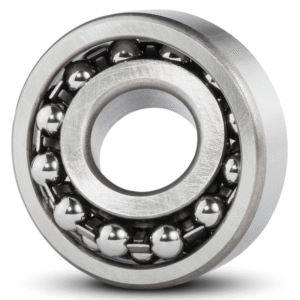

In Self Aligning Ball Bearing 2311, “2”: Indicates that the bearing type is a self aligning ball bearing. Self aligning ball bearings feature a spherical outer ring raceway and two rows of balls, allowing them to automatically adjust to angular misalignments of up to 2.5 degrees. This unique design makes them ideal for applications where shaft misalignment is likely to occur due to factors like installation errors, thermal expansion, or uneven loads. They are capable of handling both radial and axial loads simultaneously, providing excellent stability and reducing wear on connected components.

“3”: Indicates the bearing’s diameter series code. The diameter series code is used to represent the range of the bearing’s inner and outer diameter sizes. In the case of the 3 series, it typically indicates that the bearing’s dimensions belong to the medium series, which means the bearing has a moderate size and load-carrying capacity compared to other series. This series is well-suited for heavy-duty applications requiring balanced radial and axial load performance.

“11”: Indicates the bearing’s inner diameter code. The inner diameter is calculated by multiplying the code by 5, so for the 2311 bearing, its inner diameter is 11 × 5 = 55mm. This size makes it suitable for medium to large shaft applications in industrial machinery.

In the model 2311 bearing, the tolerance grade is not directly indicated but is usually assumed to be grade 0, the normal precision level. This grade balances dimensional accuracy and rotational smoothness for most general industrial applications. Higher precision grades (e.g., P5, P4) can be customized for specific needs requiring tighter tolerances.

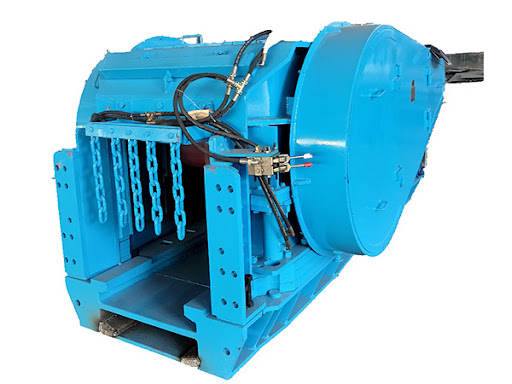

In summary, the meaning of the bearing model 2311 is: self aligning ball bearing, medium series, inner diameter of 55mm, normal precision level. This type of bearing is widely used in heavy machinery such as mining crushers, large conveyor systems, construction equipment, and industrial gearboxes, where shaft misalignment and high loads are common. Its self-aligning feature ensures reliable operation, minimizes maintenance downtime, and enhances the durability of critical equipment.

Product Application

The Self Aligning Ball Bearing 2311 is extensively applied across heavy-duty industrial sectors, leveraging its robust design to tackle severe shaft misalignment and high-load challenges.

In mining crushers, the bearing withstands extreme impacts and vibrations from crushing ore, with its self-aligning feature compensating for shaft deflections caused by uneven material loads, reducing maintenance by 40% and extending component life. Construction equipment like excavators and loaders use 2311 bearings in swing mechanisms, where they handle radial forces from heavy booms and axial forces from rotational movements, ensuring precise operation even on unstable terrain.

Large conveyor systems in ports and logistics centers rely on 2311 bearings to support heavy roller loads. The bearing’s 2.5° misalignment compensation counteracts sagging shafts from long conveyor spans, preventing belt slippage and minimizing downtime. In industrial gearboxes, it withstands combined radial loads from gear meshing and axial loads from thrust forces, maintaining smooth power transmission in cement plants and steel mills.

Textile machinery such as large-scale looms uses 2311 bearings in drive shafts, where they absorb vibrations from high-speed weaving and adjust for thermal expansion in motors, improving fabric consistency. Wind power generators employ the bearing in yaw systems, allowing nacelles to align with wind directions while resisting radial loads from rotor weights, enhancing energy capture efficiency.

Additionally, in water treatment pumps and industrial fans, the bearing’s dual-row ball design ensures reliable operation in humid or dusty environments, making it indispensable for heavy-industry applications demanding durability and misalignment tolerance.

Product List

| Bearing No. |

Dimensions (mm) |

Basic Load Rating (N) |

Weight (kg) |

|

|

|

|

| ISO |

GOST |

d |

D |

B |

Dyn. C |

Stat. C0 |

|

| 2300 |

1600 |

10 |

35 |

17 |

10000 |

2100 |

0.08 |

| 2301 |

1601 |

12 |

37 |

17 |

11400 |

2600 |

0.091 |

| 2302 |

1602 |

15 |

42 |

17 |

11800 |

2800 |

0.108 |

| 2303 |

1603 |

17 |

47 |

19 |

14300 |

3500 |

0.168 |

| 2304 |

1604 |

20 |

52 |

21 |

17800 |

4750 |

0.21 |

| 2305 |

1605 |

25 |

62 |

24 |

24500 |

6480 |

0.335 |

| 2306 |

1606 |

30 |

72 |

27 |

31500 |

8680 |

0.5 |

| 2307 |

1607 |

35 |

80 |

31 |

39200 |

11000 |

0.675 |

| 2308 |

1608 |

40 |

90 |

33 |

44800 |

13200 |

0.925 |

| 2309 |

1609 |

45 |

100 |

36 |

55000 |

16200 |

1.23 |

| 2310 |

1610 |

50 |

110 |

40 |

64500 |

19800 |

1.63 |

| 2311 |

1611 |

55 |

120 |

43 |

75200 |

23500 |

2.09 |

| 2312 |

1612 |

60 |

130 |

46 |

86800 |

27500 |

2.6 |

| 2313 |

1613 |

65 |

140 |

48 |

96000 |

32500 |

3.2 |

| 2314 |

1614 |

70 |

150 |

51 |

110000 |

37500 |

3.92 |

| 2315 |

1615 |

75 |

160 |

55 |

122000 |

42800 |

4.78 |

| 2316 |

1616 |

80 |

170 |

58 |

128000 |

45500 |

5.65 |

Reviews

There are no reviews yet.