Description

Basic Parameters

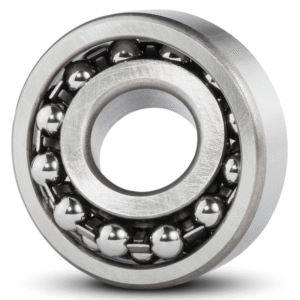

In bearing 1208, “1”: Indicates that the bearing type is a self-aligning ball bearing. Characterized by a spherical outer ring raceway and two rows of balls, this bearing can automatically compensate for shaft misalignment or angular deflection (up to 2–3 degrees), making it suitable for applications where precise alignment is difficult to maintain. It primarily handles radial loads and moderate bidirectional axial loads. “2”: Represents the diameter series code, which defines the relative proportions of the bearing’s inner and outer diameters. The 2 series signifies a light series, meaning the bearing offers a balanced combination of compact size and adequate load-carrying capacity for its 40mm inner diameter. “08”: Denotes the inner diameter code. Using the standard calculation (inner diameter = code × 5), the actual inner diameter of the 1208 bearing is 08 × 5 = 40mm.

Product Application

In medium-sized electric motors (e.g., 3-phase induction motors, gear motors) and generators, the 1208 bearing compensates for misalignments caused by thermal expansion, flexible couplings, or uneven mounting. Its spherical outer ring and dual-row ball design reduce stress from shaft deflection, minimizing vibration and noise in high-speed operations. Ideal for applications with radial loads from rotating armatures and moderate axial loads from belt-driven pulleys or gear reducers, ensuring extended motor life in industrial pumps, fans, and compressors.

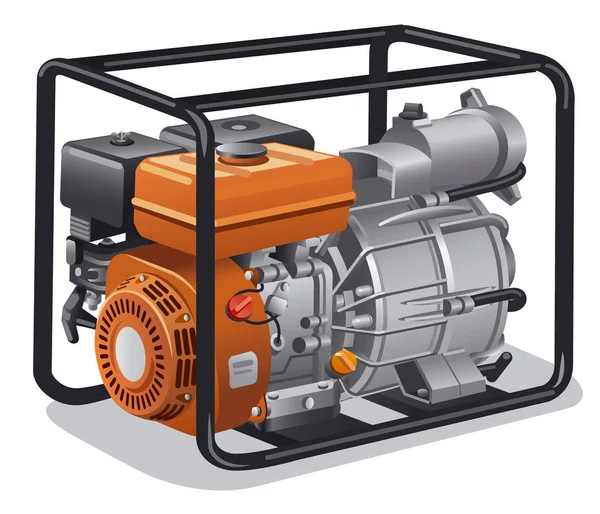

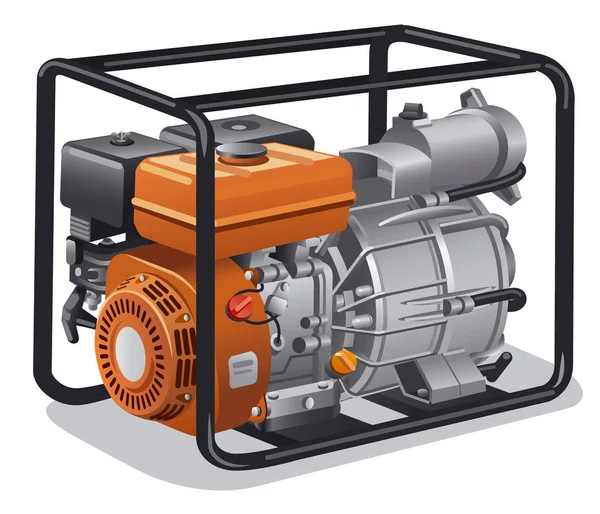

For centrifugal pumps, sewage pumps, or hydraulic systems, where shafts may bend under fluid pressure or cavitation forces, the 1208 bearing’s self-aligning feature mitigates premature wear from misalignment. It efficiently handles radial loads from impeller rotation and bidirectional axial loads from fluid thrust, maintaining stable operation in wet, corrosive, or particle-laden environments. Its compact light series design (outer diameter 80mm, width 18mm) fits into space-constrained pump casings while resisting misalignment up to 2–3 degrees.

In roller conveyors, chain drives, or bulk material handling systems (e.g., in mining, food processing, or logistics), the 1208 bearing excels in supporting rollers or idlers subjected to off-center loads or frame flexure. Its self-aligning capability accommodates misalignment from uneven installation or heavy payloads, reducing friction and energy loss. The grade 0 precision ensures consistent rotational accuracy for conveyor belts requiring steady motion, while the robust design withstands dusty, high-vibration conditions with minimal maintenance.

In tractors, combines, harvesters, or irrigation systems, exposed to dirt, moisture, and dynamic loads, the 1208 bearing is ideal for gearboxes, PTO shafts, and pivot points. It handles radial loads from agricultural implements (e.g., plows, balers) and moderate axial loads from misaligned drive chains or belts, resisting contamination and wear in harsh field conditions. The self-aligning feature compensates for shaft movement due to uneven terrain, ensuring reliable performance in critical agricultural applications.

For machinery with moderate load requirements and space limitations, such as woodworking lathes, textile machine spindles, or printing presses, the 1208 bearing offers a balance of compactness and load capacity. It mitigates misalignment from worn mounts or flexible drive components, reducing stress on adjacent parts and extending service intervals. The standard precision grade (grade 0) meets most industrial accuracy needs, making it a cost-effective choice for non-critical high-speed applications.

Product List

| Bearing No. |

Dimensions (mm) |

Basic Load Rating (N) |

Weight (kg) |

|

|

|

|

| ISO |

GOST |

d |

D |

B |

Dyn. C |

Stat. C0 |

|

| 1200 |

1200 |

10 |

30 |

9 |

5480 |

1200 |

0.034 |

| 1201 |

1201 |

12 |

32 |

10 |

5550 |

1250 |

0.04 |

| 1202 |

1202 |

15 |

35 |

11 |

7480 |

1750 |

0.049 |

| 1203 |

1203 |

17 |

40 |

12 |

7900 |

2020 |

0.073 |

| 1204 |

1204 |

20 |

47 |

14 |

9950 |

2650 |

0.116 |

| 1205 |

1205 |

25 |

52 |

15 |

12000 |

3300 |

0.14 |

| 1206 |

1206 |

30 |

62 |

16 |

15800 |

4700 |

0.22 |

| 1207 |

1207 |

35 |

72 |

17 |

15800 |

5080 |

0.32 |

| 1208 |

1208 |

40 |

80 |

18 |

19200 |

6400 |

0.415 |

| 1209 |

1209 |

45 |

85 |

19 |

21800 |

7320 |

0.465 |

| 1210 |

1210 |

50 |

90 |

20 |

22800 |

8080 |

0.531 |

| 1211 |

1211 |

55 |

100 |

21 |

26800 |

10000 |

0.705 |

| 1212 |

1212 |

60 |

110 |

22 |

30200 |

11500 |

0.9 |

| 1213 |

1213 |

65 |

120 |

23 |

31000 |

12500 |

1.15 |

| 1214 |

1214 |

70 |

125 |

24 |

34500 |

13500 |

1.24 |

| 1215 |

1215 |

75 |

130 |

25 |

38800 |

15200 |

1.39 |

| 1216 |

1216 |

80 |

140 |

26 |

39500 |

16800 |

1.7 |

| 1217 |

1217 |

85 |

150 |

28 |

48800 |

20500 |

2.06 |

| 1218 |

1218 |

90 |

160 |

30 |

56500 |

23200 |

2.59 |

| 1219 |

1219 |

95 |

170 |

32 |

63500 |

27000 |

3.1 |

| 1220 |

1220 |

100 |

180 |

34 |

67400 |

28400 |

3.7 |

| 1224 |

1224 |

120 |

215 |

42 |

117000 |

51000 |

6.77 |

Reviews

There are no reviews yet.