Description

Basic Parameters

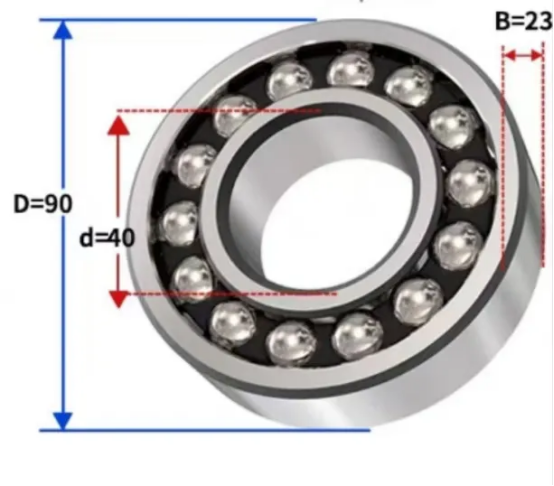

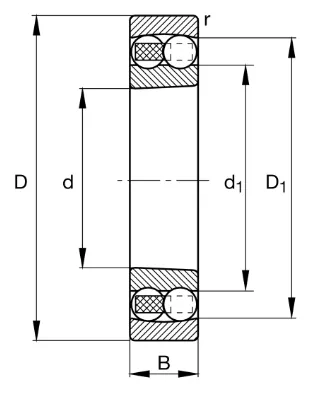

The numbers in the bearing 1308 mean the following: “1 ”represents that the bearing type is a ball bearing, “3 ”represents the width series of the bearing, and “08” represents that the inner diameter of the bearing is 40 millimeters.The 1308 bearing is a self-aligning ball bearing with an outer ring with two raceways and an inner ring with balls and a cage assembly. The model number of this type of bearing typically follows the ISO standard, where “13” indicates the bearing’s outer diameter series, and “08” indicates the bearing’s width series.

Therefore, the outer diameter of the 1308 bearing is approximately 90 millimeters, and the width is 23 millimeters.The 1308bearing is a rolling element bearing that is uniquely designed to withstand misalignment of the shaft with respect to the bearing housing. It has two volleyball balls and the outer ring has a common spherical raceway that enables the bearing to self-align. The inner diameter of the 1308 ETN9 is 40 mm. The outer diameter is 90 mm. The width is 23 mm.

The 1308 ETN9 bearing is versatile and adaptable, ensuring smooth operation even when not perfectly aligned. Its unique design helps to prevent the bearing from being stressed, thus extending its service life.

Product Application

1. Automotive Industry

Power Steering Systems: Supports steering shafts in cars and commercial vehicles, accommodating angular errors from steering mechanisms to ensure smooth and responsive control.

Drive Shafts & Steering Columns: Used in drive train components and steering joints, where misalignment from road vibrations or assembly tolerances is common, reducing stress and noise.

2. Agricultural Machinery

Tractors & Harvesters: Installed in gearboxes, axle bearings, and conveyor systems of farm equipment, handling shaft eccentricity caused by uneven terrain or heavy loads.

Irrigation Pumps: Provides stable support for pump shafts in irrigation systems, minimizing wear from misalignment due to mechanical stress or installation errors.

3. Textile Machinery

Spinning Machines & Looms: Ensures consistent, low-vibration rotation in high-speed textile equipment, where misalignment can cause yarn breakage or fabric defects.

Roller Systems: Used in fabric rolling and processing lines to maintain alignment and smooth operation, even under varying tension loads.

4. Conveyor & Material Handling

Belt Conveyors: Supports rollers in long-distance conveyor systems, compensating for misalignment from belt tension or frame deflection to prevent belt slippage or premature wear.

Bucket Elevators: Applied in grain or bulk material handling systems, enduring shaft misalignment and heavy radial loads in continuous operation.

5. Mining & Construction

Crushers & Vibrating Screens: withstands harsh conditions in mining equipment, such as jaw crushers or vibrating screens, where shaft misalignment and impact loads are frequent.

Excavators & Bulldozers: Used in swing mechanisms and track drive systems, providing self-aligning support for improved durability in rough terrain.

6. Industrial Equipment

Pumps & Fans: Installed in centrifugal pumps and industrial fans, reducing vibration and noise caused by shaft misalignment, thereby enhancing energy efficiency.

Woodworking Machinery: Supports spindle shafts in saws and planers, ensuring precise cutting performance even with minor misalignments from thermal expansion or heavy-duty use.

Product List

| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight | ||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | (kg) |

| 1300 | 1300 | 10 | 35 | 11 | 7220 | 1620 | 0.058 |

| 1301 | 1301 | 12 | 37 | 12 | 9420 | 2120 | 0.067 |

| 1302 | 1302 | 15 | 42 | 13 | 9500 | 2280 | 0.094 |

| 1303 | 1303 | 17 | 47 | 14 | 12500 | 3180 | 0.13 |

| 1304 | 1304 | 20 | 52 | 15 | 12500 | 3380 | 0.165 |

| 1305 | 1305 | 25 | 62 | 17 | 17800 | 5050 | 0.255 |

| 1306 | 1306 | 30 | 72 | 19 | 21500 | 6280 | 0.385 |

| 1307 | 1307 | 35 | 80 | 21 | 25000 | 7950 | 0.51 |

| 1308 | 1308 | 40 | 90 | 23 | 29500 | 9500 | 0.715 |

| 1309 | 1309 | 45 | 100 | 25 | 38000 | 12800 | 0.955 |

| 1310 | 1310 | 50 | 110 | 27 | 43200 | 14200 | 1.2 |

| 1311 | 1311 | 55 | 120 | 29 | 51500 | 18200 | 1.6 |

| 1312 | 1312 | 60 | 130 | 31 | 57200 | 21200 | 1.95 |

| 1313 | 1313 | 65 | 140 | 33 | 61800 | 22800 | 2.42 |

| 1314 | 1314 | 70 | 150 | 35 | 74500 | 27500 | 3 |

| 1315 | 1315 | 75 | 160 | 37 | 79000 | 29800 | 3.55 |

| 1316 | 1316 | 80 | 170 | 39 | 86700 | 31400 | 4.17 |

| 1317 | 1317 | 85 | 180 | 41 | 97800 | 37800 | 5 |

| 1318 | 1318 | 90 | 190 | 43 | 115000 | 42000 | 5.8 |

| 1319 | 1319 | 95 | 200 | 45 | 132000 | 50800 | 6.7 |

| 1320 | 1320 | 100 | 215 | 47 | 141000 | 55000 | 8.3 |

| 2200 | 1500 | 10 | 30 | 14 | 8000 | 1800 | 0.048 |

| 2201 | 1501 | 12 | 32 | 14 | 8400 | 1900 | 0.052 |

| 2202 | 1502 | 15 | 35 | 14 | 8600 | 2000 | 0.056 |

| 2203 | 1503 | 17 | 40 | 16 | 10400 | 2500 | 0.087 |

| 2204 | 1504 | 20 | 47 | 18 | 16400 | 4100 | 0.13 |

| 2205 | 1505 | 25 | 52 | 18 | 15200 | 3900 | 0.16 |

| 2206 | 1506 | 30 | 62 | 20 | 15200 | 4600 | 0.26 |

| 2207 | 1507 | 35 | 72 | 23 | 21800 | 6650 | 0.405 |

| 2208 | 1508 | 40 | 80 | 23 | 22500 | 7380 | 0.505 |

| 2209 | 1509 | 45 | 85 | 23 | 23200 | 8000 | 0.54 |

| 2210 | 1510 | 50 | 90 | 23 | 23200 | 8450 | 0.58 |

| 2211 | 1511 | 55 | 100 | 25 | 26800 | 9950 | 0.8 |

| 2212 | 1512 | 60 | 110 | 28 | 34000 | 12500 | 1.09 |

| 2213 | 1513 | 65 | 120 | 31 | 43500 | 16200 | 1.45 |

| 2214 | 1514 | 70 | 125 | 31 | 44000 | 17000 | 1.5 |

| 2215 | 1515 | 75 | 130 | 31 | 44200 | 18000 | 1.6 |

| 2216 | 1516 | 80 | 140 | 33 | 48800 | 20200 | 2.15 |

| 2217 | 1517 | 85 | 150 | 36 | 58200 | 23500 | 2.67 |

| 2218 | 1518 | 90 | 160 | 40 | 70000 | 28500 | 3.37 |

| 2220 | 1520 | 100 | 180 | 46 | 97200 | 40500 | 4.94 |

Reviews

There are no reviews yet.