Description

Basic Parameters

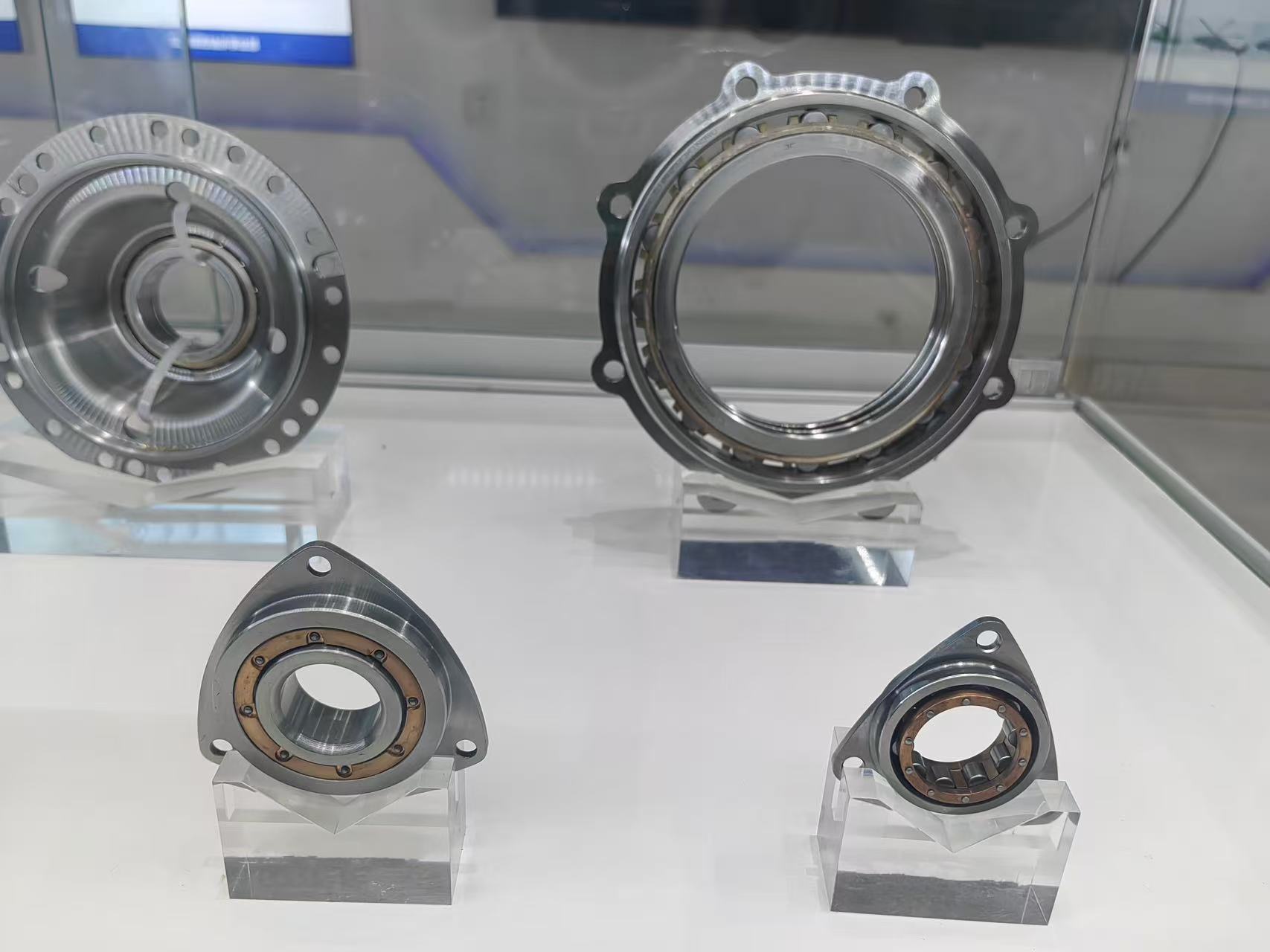

The basic parameters of the Special Bearing include: It is a special bearing designed for high – end precision fields such as aviation, aerospace, navigation and nuclear industry. It has core performances like resistance to high/low temperature, high speed/heavy load, vacuum/radiation/magnetic field and high – precision positioning. The main material is special alloy steel (such as high – temperature alloy and titanium alloy), and the surface is treated by coating for corrosion prevention and precision grinding. The precision grades are optional as P4 (precision grade) and P2 (ultra – precision grade). It also supports customization of non – standard dimensions and special working conditions (such as extreme temperature and strong corrosion environment).

Product Performance

Extreme Environment Adaptability

Wide Temperature Range Stability: Capable of maintaining structural integrity and lubrication performance in extreme temperatures ranging from -200°C to +600°C, suitable for applications like aircraft engine combustion chambers and spacecraft cryogenic propulsion systems.

Resistance to Complex Media: Constructed with corrosion-resistant alloy materials and sealed technology, it withstands long-term erosion from fuels, hydraulic oils, seawater, radiation, and other media, meeting the demands of marine equipment, nuclear reactors, and other harsh environments.

High Load and Speed Performance

Heavy-Duty Support Capacity: With optimized raceway design and material strength, its dynamic load capacity is 30% higher than conventional bearings, ideal for heavy-load scenarios such as spacecraft robotic arm joints and main shafts of heavy industrial equipment.

High-Speed Rotation Stability: Precision-machined spherical raceways and low-friction cages enable operation at speeds up to 100,000 RPM, reducing heat generation and vibration to enhance the efficiency of aviation turbine machinery.

Precision Manufacturing and Longevity

Nanometer-Level Machining Precision: Critical dimensional tolerances are controlled within ±2μm, ensuring precise 对接 (docking) with mating components for high-precision applications like navigation system gyroscopes and precision optical instruments.

Long-Life Design: Stress distribution optimized via finite element analysis, combined with self-lubricating materials, extends service life by 50% compared to similar products, reducing maintenance frequency for aerospace equipment.

Multi-Functional Integrated Design

Composite Performance Integration: Capable of simultaneously achieving anti-magnetic interference, radiation resistance, vacuum sealing, and other functions, meeting the comprehensive requirements of complex working conditions in nuclear industrial equipment and satellite attitude control systems.

Product Applications

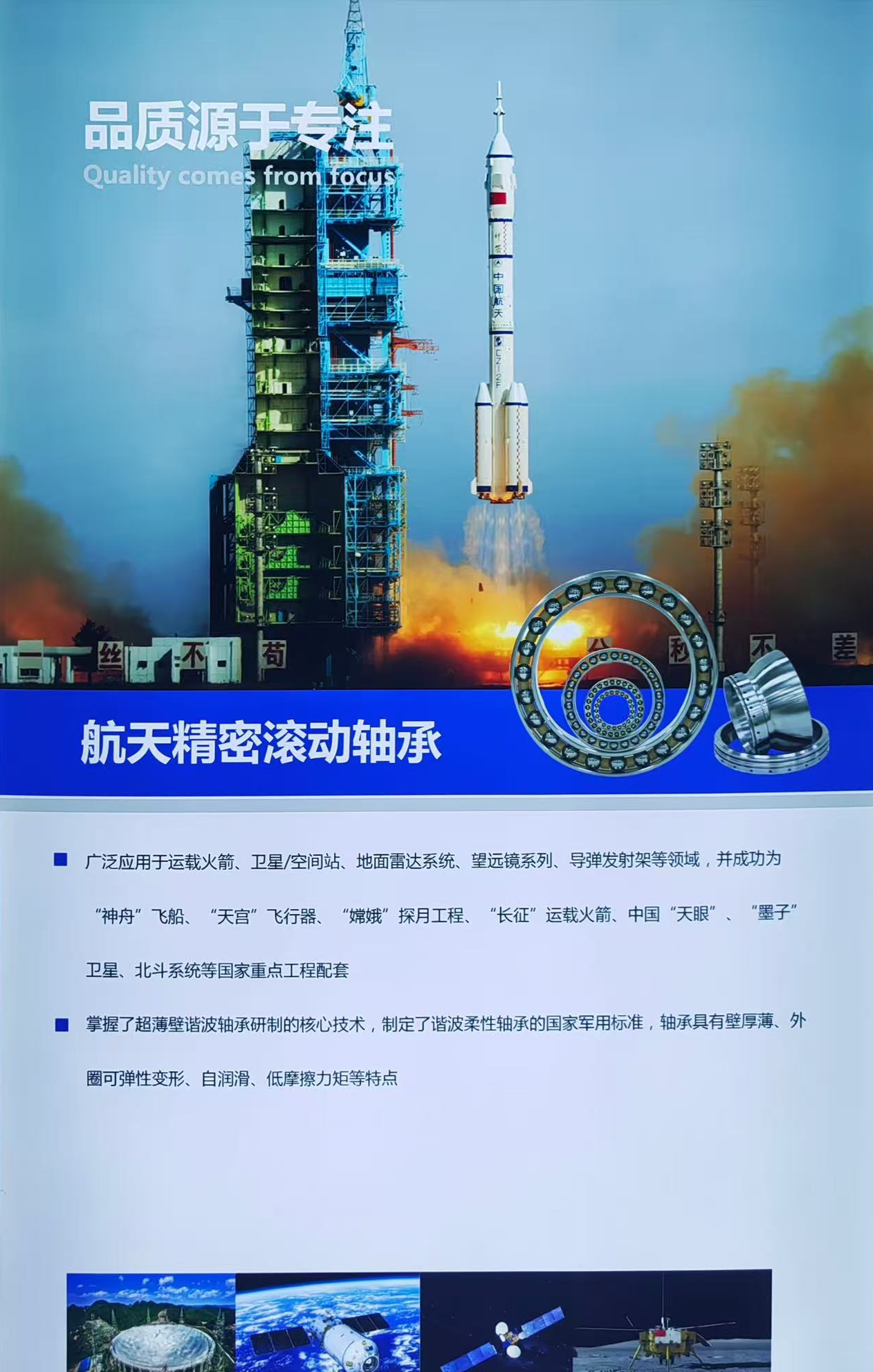

Aerospace Industry

Aircraft Power Systems: Used in turbine bearings of aircraft engines and rotating joints of rocket thrusters to ensure reliable operation under high-temperature and high-speed conditions.

Spacecraft Instruments: Applied in drive mechanisms of satellite solar panels and bearing systems of manned spacecraft life support equipment, adapted to the vacuum and radiation environments of space.

Marine and Nuclear Industries

Marine Critical Components: Installed in submarine propeller shafts and bearings of offshore engineering cranes, resisting seawater corrosion and impact loads.

Nuclear Facilities: Used in control rod drive mechanisms of nuclear reactors and radioactive material transportation systems, meeting requirements for radiation resistance and long service life.

High-End Industrial and Research Fields

Precision Instruments: Serves in cutting-edge equipment such as lithography machines and particle accelerators, providing nanometer-level positioning accuracy and anti-interference capabilities.

Special Machinery: Suitable for bearings in high-temperature furnace robotic arms and deep-sea exploration equipment, addressing extreme working conditions beyond the capability of conventional bearings.

Product Services

We can provide customized processing based on your working environment, rotation speed requirements, and can also carry out processing according to provided drawings or samples.

Reviews

There are no reviews yet.