Description

Basic Parameters

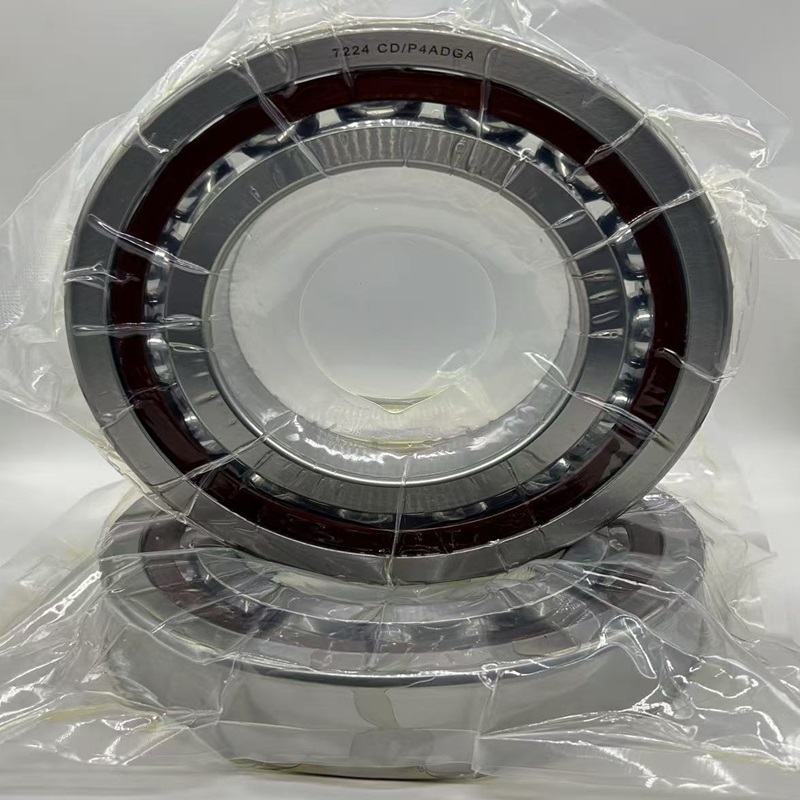

Super precision ball bearings are engineered for applications requiring extreme accuracy, high speed, and long service life. They are widely used in CNC spindles, robotics, grinding machines, medical devices, and aerospace systems.Manufactured to tight tolerance classes (ABEC-7/9 or ISO P4/P2), these bearings are available in angular contact, deep groove, and thrust types, with bore sizes ranging from 5 mm to 120 mm. Optimized contact angles (15°, 25°, 30°) ensure balanced axial and radial load handling.Rolling elements are made from high-grade steel or silicon nitride ceramic for reduced weight and thermal expansion. Cage materials include phenolic resin, polyamide, or brass—chosen for strength and low friction. This advanced design supports speeds up to 100,000 rpm with low heat and vibration.Multiple lubrication methods—grease, oil mist, air-oil—are supported. Bearings can be customized with specific preload and clearance settings to meet precise application needs.Reliable, repeatable, and robust, super precision ball bearings drive the performance of modern high-precision manufacturing and automation.

Product Application

1. CNC Machine Tools and High-Speed Spindles

Super precision ball bearings are critical components in CNC machining centers and high-speed spindle systems. Their high rotational accuracy and low vibration ensure superior surface finishes, tight tolerances, and extended spindle life. These bearings support high-speed cutting, drilling, and milling operations in industries such as mold manufacturing, aerospace, and automotive machining.

2. Precision Grinding Machines

In high-frequency and ultra-precision grinding machines, super precision bearings deliver the stability and rigidity required for micron-level surface finish and form accuracy. Their ability to operate at extremely high speeds with minimal thermal distortion makes them ideal for internal, external, and surface grinding processes.

3. Robotics and Automation

Robotic arms and automation systems demand compact, lightweight, and highly responsive components. Super precision ball bearings enable smooth articulation and repeatable motion control in joints, end-effectors, and linear actuators. Their low-friction performance enhances energy efficiency and dynamic responsiveness in industrial robots and collaborative automation systems.

4. Medical Equipment

In high-precision medical devices such as surgical tools, dental turbines, and diagnostic machines (e.g., CT scanners), these bearings provide quiet, vibration-free operation and long-term reliability. Their materials and sealing options can be tailored for sterile, high-speed, or low-noise environments.

5. Aerospace and Defense

Aerospace systems require components that can perform reliably under extreme loads, speeds, and temperature variations. Super precision ball bearings are used in gyroscopes, navigation units, fuel pumps, and control mechanisms, where high stiffness and zero-failure tolerance are paramount.

6. Semiconductor and Optical Equipment

In semiconductor fabrication and optical inspection systems, these bearings ensure ultra-precise positioning and minimal particle generation. Their ultra-low vibration and high cleanliness standards meet the stringent requirements of cleanroom environments and nanotechnology processes.

Reviews

There are no reviews yet.