Description

Basic Parameters

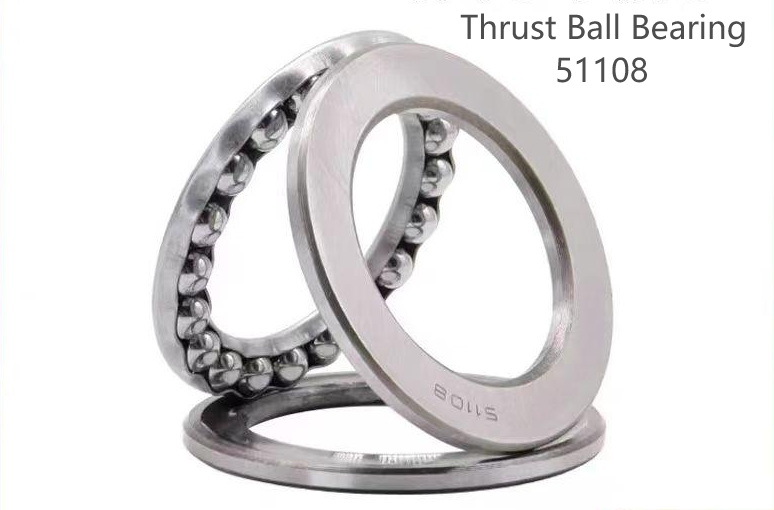

The FODA thrust ball bearing 51108 (old model: 8108) is a single-direction axial load – bearing solution. It has an inner diameter of 40 mm, an outer diameter of 68 mm, and a thickness of 15 mm. The rated dynamic axial load is 50,500N, and the static axial load is 92,200N. This bearing is made of 52100 bearing steel (HRC 58 – 62), which has high wear resistance. It features a detachable design for easy maintenance. The precisely ground inner hole ensures a firm fit with the shaft. It is pre – lubricated for easy installation. It is suitable for applications that require single – direction axial support, such as machine tool spindles, automotive transmissions, and industrial pumps.

Features and Performance

Unidirectional Axial Load Capacity

Detachable Component Structure

Precision-Ground Inner Ring Bore

Low-Friction Groove Design

Product Application

1.Precision Machine Tools and Processing Equipment

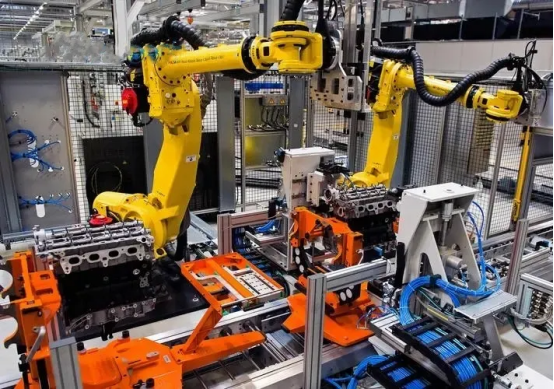

2.Automobiles and Transportation Equipment

Automobile Clutches and Transmissions:

Installed on the clutch shaft of a manual transmission, it withstands axial pressure when the clutch is engaged, enabling smooth gear shifting. In the oil pump shaft of an automatic transmission, it endures the axial load generated by high – speed rotation. Its pre – lubrication design can reduce maintenance frequency to adapt to a compact vehicle layout.

Commercial Vehicle Suspension Systems

Located at the articulation points of the truck’s balance shaft or suspension, it is used to absorb the axial impact caused by road bumps. The 52100 bearing steel material (HRC 58–62) can resist wear caused by long – term vibration, thereby improving ride comfort.

Vertical shafts of vertical pumps and compressors:

Used at the lower end of the impeller shafts of deep well pumps and vertical centrifugal pumps to support the unidirectional axial thrust generated by fluid pressure (such as water pressure reaction force), prevent shaft misalignment, and ensure the efficient operation of the pump. In screw compressors, it bears the axial load generated by the screw to maintain the seal of the compression chamber.

Rotors of generators and motors

Located at the shaft end of the rotors of small and medium-sized motors, it bears the axial force generated by magnetic pull. The detachable structure (separable inner and outer rings) can be quickly disassembled during motor maintenance, reducing downtime and costs.

3.Lifting and Construction Machinery

Winches and Lifting Equipment: Installation

At the end of the drum shaft of electric hoists and small cranes, it is used to bear the axial load generated by the tension of the wire rope. Its static load capacity is as high as 92,200N, and it can withstand sudden overloads, ensuring safe operation. Its compact size (outer diameter 68 mm × thickness 15 mm) is very suitable for lifting machinery with limited space.

Construction Machinery Jacking SystemIt is used at the shaft end of hydraulic jacks or cylinders of construction hoists. Through one-way load-bearing, it ensures stable control during the jacking process. The smooth surface design can minimize dust accumulation and is suitable for harsh outdoor conditions.

4.Automation and Light Industry Equipment

Product List

| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight (kg) | ||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | |

| 51100 | 8100 | 10 | 24 | 9 | 10000 | 14000 | 0.02 |

| 51101 | 8101 | 12 | 26 | 9 | 10400 | 15300 | 0.022 |

| 51102 | 8102 | 15 | 28 | 9 | 10600 | 16600 | 0.023 |

| 51103 | 8103 | 17 | 30 | 9 | 11400 | 19600 | 0.025 |

| 51104 | 8104 | 20 | 35 | 10 | 12700 | 20800 | 0.038 |

| 51105 | 8105 | 25 | 42 | 11 | 15900 | 29000 | 0.056 |

| 51106 | 8106 | 30 | 47 | 11 | 16800 | 33500 | 0.063 |

| 51107 | 8107 | 35 | 52 | 12 | 17400 | 37500 | 0.08 |

| 51108 | 8108 | 40 | 60 | 13 | 23400 | 50000 | 0.12 |

| 51109 | 8109 | 45 | 65 | 14 | 24200 | 57000 | 0.14 |

| 51110 | 8110 | 50 | 70 | 14 | 25500 | 63000 | 0.16 |

| 51111 | 8111 | 55 | 78 | 16 | 30700 | 78000 | 0.247 |

| 51112 | 8112 | 60 | 85 | 17 | 36400 | 93000 | 0.33 |

| 51113 | 8113 | 65 | 90 | 18 | 37100 | 98000 | 0.359 |

| 51114 | 8114 | 70 | 95 | 18 | 37700 | 104000 | 0.385 |

| 51115 | 8115 | 75 | 100 | 19 | 44200 | 137000 | 0.4 |

| 51116 | 8116 | 80 | 105 | 19 | 44900 | 140000 | 0.42 |

| 51117 | 8117 | 85 | 110 | 19 | 46200 | 150000 | 0.44 |

| 51118 | 8118 | 90 | 120 | 22 | 59200 | 190000 | 0.67 |

| 51120 | 8120 | 100 | 135 | 25 | 85200 | 270000 | 0.97 |

| 51122 | 8122 | 110 | 145 | 25 | 87100 | 290000 | 1.05 |

| 51124 | 8124 | 120 | 155 | 25 | 88400 | 310000 | 1.15 |

| 51126 | 8126 | 130 | 170 | 30 | 111000 | 390000 | 1.85 |

| 51128 | 8128 | 140 | 180 | 31 | 112000 | 400000 | 2.05 |

| 51130 | 8130 | 150 | 190 | 31 | 112000 | 400000 | 2.2 |

| 51132 | 8132 | 160 | 200 | 31 | 112000 | 425000 | 2.35 |

| 51134 | 8134 | 170 | 215 | 34 | 133000 | 500000 | 3.3 |

| 51136 | 8136 | 180 | 225 | 34 | 135000 | 530000 | 3.5 |

| 51138 | 8138 | 190 | 240 | 37 | 172000 | 655000 | 4.05 |

| 51140 | 8140 | 200 | 250 | 37 | 174000 | 655000 | 4.25 |

| 51144 | 8144 | 220 | 270 | 37 | 178000 | 735000 | 4.6 |

| 51148 | 8148 | 240 | 300 | 45 | 234000 | 965000 | 7.55 |

| 51152 | 8152 | 260 | 320 | 45 | 238000 | 1020000 | 8.1 |

| 51156 | 8156 | 280 | 350 | 53 | 319000 | 1460000 | 12 |

| 51160 | 8160 | 300 | 380 | 62 | 364000 | 1760000 | 17.5 |

| 51164 | 8164 | 320 | 400 | 63 | 371000 | 1860000 | 19 |

| 51168 | 8168 | 340 | 420 | 64 | 377000 | 1960000 | 20 |

| 51172 | 8172 | 360 | 440 | 65 | 390000 | 2000000 | 21.8 |

| 51176 | 8176 | 380 | 460 | 65 | 398000 | 2180000 | 22.75 |

| 51180 | 8180 | 400 | 480 | 65 | 403000 | 2250000 | 24.2 |

Reviews

There are no reviews yet.