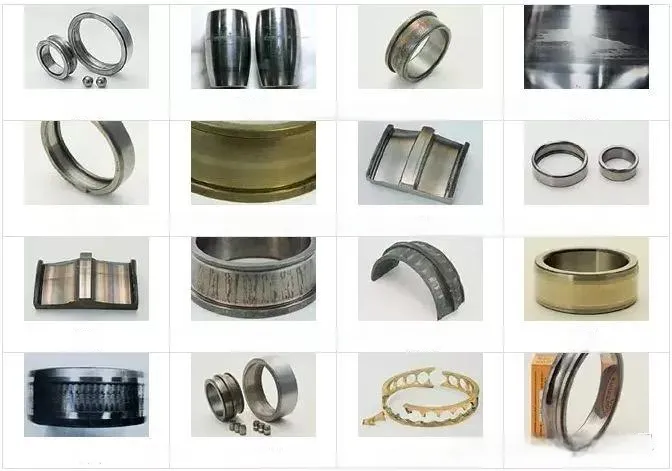

Indentations cover the raceway surface and the roller surface, there are particles on the cage, the raceway surface is worn, and the lubricating grease (lubricant) changes color. Usually, this situation is caused by unclean installation. Keep the installation site clean, use new lubricating grease, and check the integrity of the seal at the same time.

Wear caused by poor lubrication. The surface wear is mirror-like, and the color is blue or brown. This situation is caused by insufficient lubrication. The lubrication condition should be checked, and the lubrication cycle and oil seal should be re-determined.

Indentations caused by improper installation. There are indentations on the working surfaces of both the inner and outer rings, and the spacing is equal to the distance between the rollers. The reasons are that the correct ring was not machined during installation, or it was pushed too tightly onto the tapered shaft, or it was overloaded under static conditions.

Indentations caused by foreign objects. The working surface and the roller surface are covered with indentations. This may be caused by foreign objects brought in during installation, foreign objects in the lubricant, or the surrounding environment. Thoroughly clean the bearing during installation, use clean lubricant, and check the oil seal.

Scratches on the end face of the roller. There is friction between the end face of the roller and the guide rib, resulting in scratches and discoloration. This situation is caused by excessive axial load or insufficient lubrication, leading to slippage. For such damage, a lubricant with a higher viscosity can be selected.

Wear between the roller and the raceway. There is wear and local discoloration at the starting end of the raceway load zone and on the roller. This is caused by the sudden acceleration of the roller when it enters the load zone. There are two feasible solutions: one is to select a lubricant with a higher viscosity; the other is to reduce the bearing clearance.

Outer surface wear. There are scratches and local discoloration on the inner bore of the inner ring and the outer surface of the outer ring. This situation is caused by the relative movement between the ring and the shaft or the bearing seat. The only solution is to increase the interference fit between the ring and the shaft or the bearing seat to prevent relative rotation. Axial braking or clamping cannot solve this kind of problem.

Surface pitting. Small and shallow pitting marks appear on the surface of the raceway, rolling elements, or large cross-sections, presenting damage in a crystalline state. This is caused by poor lubrication. For example, lack of oil or viscosity changes caused by temperature rise make the oil film unable to separate the contact surfaces, resulting in instantaneous contact between the surfaces. Solution: Improve the lubrication.

Fretting corrosion. This is a phenomenon that occurs when there is relative movement between the bearing ring and the shaft or the bearing seat. This is caused by an overly loose fit or deformation of the bearing seat.

Electrical erosion. Dark brown or gray-black straight stripes or pitted surfaces appear on the surface of the rolling elements. When an electric current passes through the bearing, weld marks are generated on the surface of the bearing parts. Solution: Prevent the electric current from passing through the bearing.

Spalling at symmetrical positions on the rolling surface. There are obvious stress marks at radially symmetrical positions on one of the two rings, and there is surface spalling. This is caused by deformation or elliptical compression of the bearing housing. Remanufacture the bearing housing.

Spalling caused by axial load. The stress marks are obvious, and spalling occurs on one side of the double-row bearing ring or on the surface of a certain raceway. Reasons: a. Axial load caused by incorrect installation; b. Excessive preload; c. The non-fixed bearing is stuck or the reserved axial displacement is insufficient.

Spalling caused by indentations. The surface of the raceway spalls, and indentations equal to the spacing of the rollers appear. This is caused by the bearing being overloaded under static conditions due to incorrect installation. Other minor indentations may be caused by foreign objects brought in during installation or foreign objects in the lubricant.

Cracks caused by rough installation and knocking. These cracks are notch-shaped notches and usually only appear on one side. This is caused by the impact force being transmitted from rough knocking through the rolling elements to the end face of the ring. Do not directly knock on the bearing ring.

Cracks caused by excessive squeezing. The cracks run through the entire cross-section. This is caused by an excessive interference fit of the inner ring of the bearing or excessive pushing of the tapered shaft.

Cracks caused by frictional corrosion. The cracks on the inner ring are transverse, and the cracks on the outer ring are circumferential. This is caused by an overly loose fit of the bearing seat or poor shape.

Spalling caused by fretting corrosion. The raceway surface of the bearing ring spalls. The outer surface of the spalling area is corroded. This is caused by an overly loose fit or incorrect shape of the bearing housing.

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More  Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More

Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More  Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More