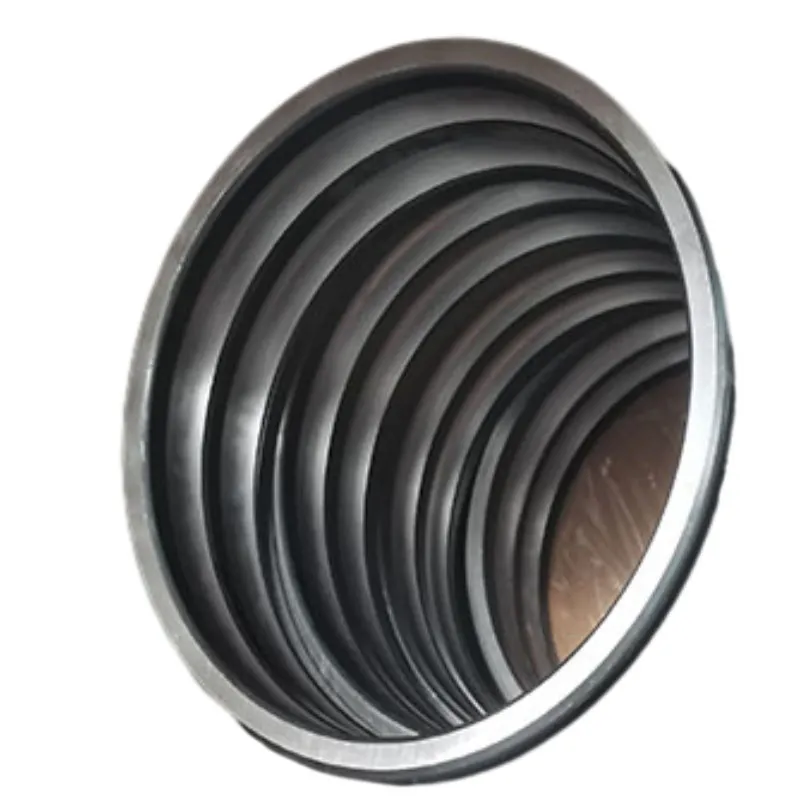

Bearing Ring

Characteristics

Characteristics

1. High precision: strict control of dimensional accuracy and geometric shape accuracy to ensure the matching accuracy with the rolling element and ensure the running accuracy and stability of the bearing.

2. High hardness and strength: can withstand large load and friction, not easy to deformation and damage.

3. Good wear resistance: in the long-term operation process, maintain good surface quality, extend the service life of the bearing.

4. Good processing performance: easy to carry out a variety of mechanical processing and heat treatment to meet different requirements.

Material

Material

1. High-carbon chromium bearing steel: such as GCr15, GCr15SiMn, etc., with high hardness, high wear resistance, good hardenability and dimensional stability.

2. Carburized bearing steel: such as G20CrNi2MoA, etc., through carburizing treatment to improve the surface hardness and wear resistance, while maintaining the toughness of the heart.

3. Stainless bearing steel: such as 9Cr18, 9Cr18Mo, etc., has good corrosion resistance, suitable for bearings in special environments.

4. High temperature bearing steel: such as Cr4Mo4V, etc., can maintain high hardness and strength in high temperature environment.

Basic Parameters

Basic Parameters

1. Inner diameter and outer diameter: the diameter of the inner hole and outer ring of the bearing ring, respectively, varies according to different bearing models and specifications.

2. Width: the axial size of the ring also varies according to the bearing type and specifications.

3. Chamfer size: In order to facilitate installation and avoid stress concentration, the inner and outer diameter edge of the ring is usually provided with chamfer, and its size has certain standard requirements.

4. Surface roughness: It affects the friction, wear and lubrication performance of bearings, and generally requires a higher surface finish.

5. Hardness: Usually between HRC58-64, different materials and heat treatment process will be different.

- Previous: Bearing Steel Ball

- Next: Non-Standard Bearing

RELATED PRODUCTS