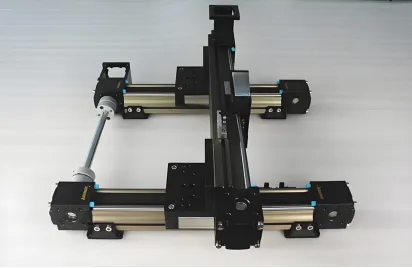

Synchronous belt linear module

Working Principle

Working Principle

The motor (servo or stepper motor) drives the driving wheel of the synchronous belt to rotate, and then the slider on the linear guide rail is driven by the belt to move back and forth. Usually, the linear module of the synchronous belt is specially designed, and the tightness of the belt movement can be controlled on one side to facilitate the debugging of the equipment in the production process

-

Synchronous belt linear module

-

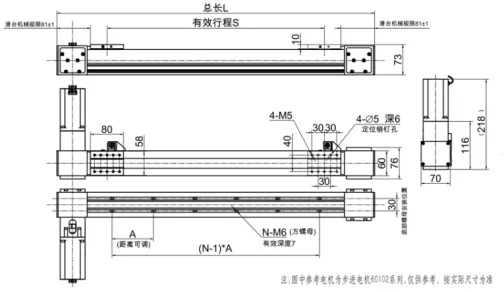

Synchronous belt linear module-Drawing

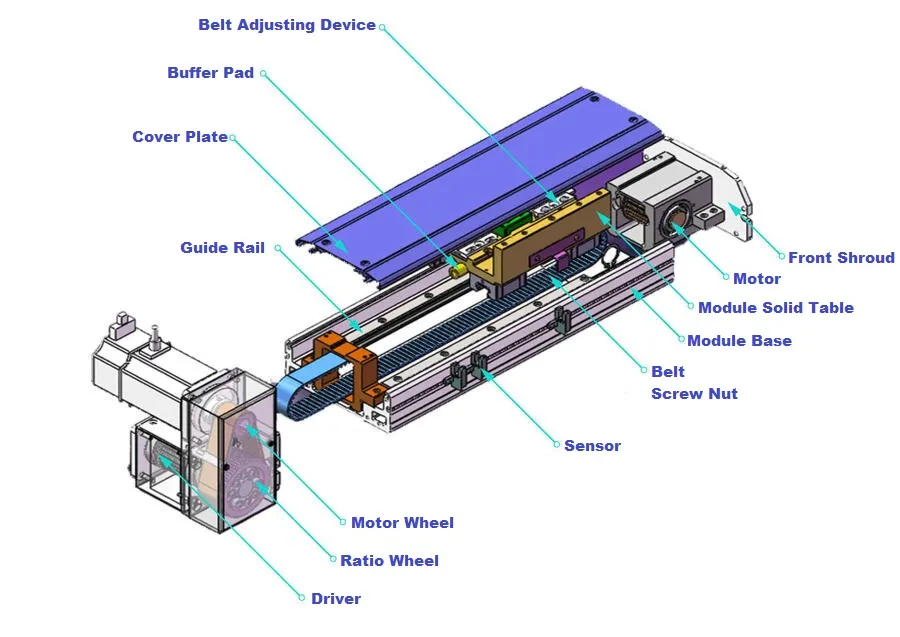

Product Component Part

Product Component Part

Belt: is the key component to achieve transmission, usually the use of high-strength, wear-resistant synchronous belt, its tooth shape and the tooth groove of the belt pulley match to ensure the accuracy and stability of the transmission.

Linear guide: used to support and guide the movement of the slider to ensure that the slider can move accurately along the straight direction, with high precision, high rigidity and low friction characteristics.

Aluminum alloy profile: As the main structure of the module, it has the advantages of beautiful appearance, reasonable design, good rigidity and reliable performance, and can provide a stable installation basis for other components.

Coupling: Used to connect the motor shaft and the driving wheel shaft of the synchronization belt, to transfer torque and compensate for the installation error between the two axes.

Motor: that is, the motor provides power for the module, common servo motor and stepper motor, can be selected according to the actual needs of the appropriate motor type and power.

Photoelectric switch: used to detect the position of the slider, to achieve accurate control and positioning of the slider movement, can set the origin, limit and other functions.

Slider: is a load bearing component, fixed connection with the belt, sliding on the linear guide rail to achieve the linear movement of the load.

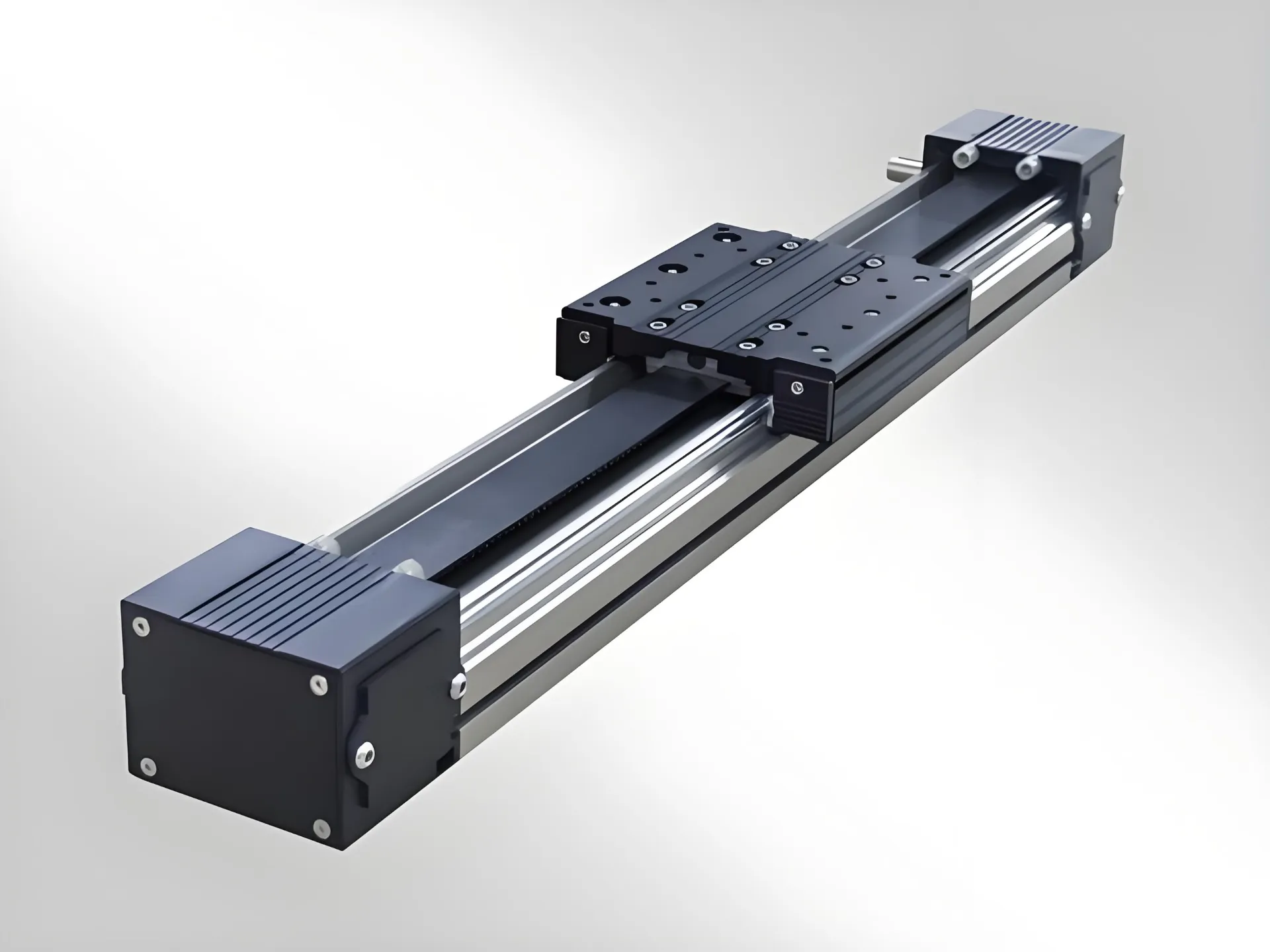

Product Characteristics

Product Characteristics

Simple structure, stable operation: relatively few components, installation and debugging is more convenient, and it is not easy to fail during operation, and can run stably for a long time.

High speed and long stroke: It can achieve higher speed than the linear screw module, and has more advantages in long stroke transmission, which can meet some application scenarios with higher requirements for speed and stroke.

High load, high repeat positioning accuracy: through reasonable selection of belt, guide rail and other components specifications, can provide a higher load capacity, but also to ensure a high repeat positioning accuracy, the general repeat positioning accuracy up to ±0.05mm.

Low noise and low wear: Compared with other transmission methods, the synchronous belt transmission mode has lower noise and wear, which can reduce the noise pollution during the operation of the equipment and extend the service life of the components.

Customizable design: According to different load requirements, speed requirements and installation space limitations, the synchronization belt specifications, pulley diameter and guide rail length can be flexibly adjusted to meet the unique needs of various automation equipment.

Closed structure: Part of the synchronous belt module adopts a closed structure, and the protection level can reach IP66, which is suitable for use in harsh environments such as dust and humidity.

-

Synchronous belt module

-

Synchronous belt linear module

Product Application

Product Application

Automated production line: widely used in automotive manufacturing, electronic product manufacturing, food processing, pharmaceutical production and other industries of automated production line, for material transportation, positioning and assembly and other work.

Laser processing equipment: such as laser cutting, laser welding, laser engraving and other equipment, used to control the movement of the laser head, to achieve high-precision processing operation35.

Detection and measurement equipment: in the measurement instrument, optical detection equipment, etc., used to achieve the accurate movement and positioning of the measured object to ensure the accuracy of detection and measurement.

Robot field: As a linear moving part of the robot, it can be used for the arm, joint and other parts of the robot to achieve accurate movement and positioning of the robot.

3D printing equipment: In the 3D printing process, it is used to control the movement of the printing nozzle or printing platform to realize the layer printing of the 3D model.

- Previous: Rod end:SI25 T/K

- Next: Rod end:SAL50T/K

RELATED PRODUCTS