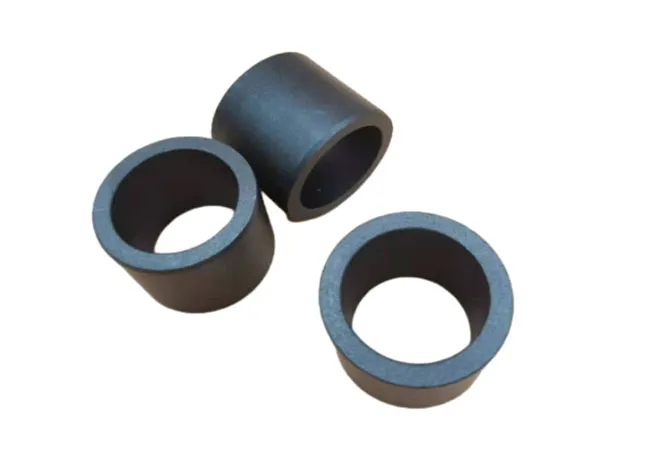

Bearing Sleeve

Characteristics

Characteristics

1. Strong wear resistance: it can withstand long-term friction and protect the shaft from wear.

2. Good lubricity: it can reduce the coefficient of friction and make the shaft run more smoothly.

3. Easy installation: It is usually installed by interference fit or tightening screw, and the operation is simple.

4. Low cost: Compared with other complex bearing components, the manufacturing cost of the shaft sleeve is relatively low.

Classification

Classification

1. By material:

- Metal bushing: such as copper bushing, steel bushing, etc., with high strength and wear resistance.

- Non-metal bushing: such as plastic bushing, rubber bushing, etc., with good corrosion resistance and shock absorption performance.

2. By shape:

Cylindrical bushing: The most common shape, suitable for most number line applications.

- Cone sleeve: used when the position or Angle of the shaft needs to be adjusted.

Basic Parameters

Basic Parameters

1. Inner diameter: the diameter of the inner hole of the shaft sleeve must match the diameter of the shaft.

2. Outer diameter: The outer diameter of the shaft sleeve determines the size of the shaft sleeve in the installation position.

3. Length: the axial length of the shaft sleeve, according to different application requirements.

4. Material: Different materials of the bushing have different performance characteristics.

5. Tolerance: allowable deviation range of shaft sleeve size.

The Working Principle

The Working Principle

The bearing bushing forms an isolation layer between the shaft and other components by fitting it closely with the shaft. When the shaft rotates, the bushing rotates with the shaft, and the coefficient of friction between the bushing and other components is small, thus reducing the wear of the shaft. At the same time, the shaft sleeve can also withstand a certain axial and radial load to ensure the stable operation of the shaft.

Application Fields

Application Fields

1. Mechanical equipment: such as motors, pumps, fans, compressors, etc., used to protect the shaft and improve the reliability of the equipment.

2. Automotive industry: Used for engine, transmission, steering system and other components to reduce friction and wear.

3. Aerospace: It plays an important role in key parts such as engines and transmission systems of aircraft and spacecraft.

4. Industrial manufacturing: widely used in various machine tools, production lines and other equipment.

5. Other fields: such as medical equipment, toys, office equipment, etc., will also use bearing sleeve.

- Previous: Precision Bearing

- Next: Rod end:SI25 T/K

RELATED PRODUCTS