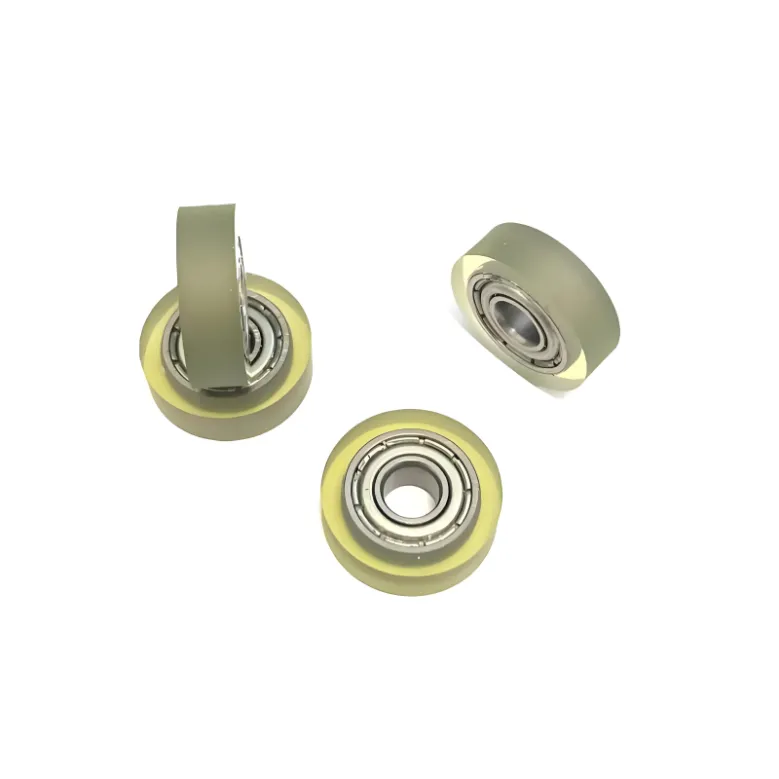

Caster & Wheel Bearing

Common used for plastic coating and injection molding Bearing models and usage

Common used for plastic coating and injection molding Bearing models and usage

Deep groove ball bearing

-686 bearing: inner diameter 6mm, outer diameter 18.6mm, thickness 7.4mm, suitable for small injection molding pulley, with low noise, explosion-proof, wear-resistant and other characteristics.

-625 bearing: inner diameter 5mm, outer diameter 16mm, often used for injection molding wheels of small equipment, can reduce noise and reduce friction, and can be customized color.

-606 bearing: size is 8.5×21×25×R3, material is ppsu shaft steel, with quiet, shock absorption and other characteristics, color can be customized.

-695 bearing: inner diameter 5mm, outer diameter 13mm, thickness 4mm, suitable for furniture hardware accessories, movable doors and Windows and other injection molding pulley, sliding flexible, no noise.

- 608 bearing: Often used in small machinery, furniture and other equipment injection wheel, can make the wheel more smooth rotation, carrying capacity is relatively small.

-6200 bearing: inner diameter 10mm, outer diameter 30mm, thickness 9mm, suitable for some medium-sized equipment injection wheel, such as industrial small transport equipment.

-6206 bearing: inner diameter 30mm, outer diameter 62mm, thickness 16mm, can withstand a certain radial and axial load, suitable for medium injection molding machine and other equipment wheels.

Production Technology

Production Technology

Plastic-coated bearings generally refer to a layer of plastic on the outer bread of the bearing, and the plastic material is generally nylon PA, polyformaldehyde POM and engineering plastics polypropylene and pp. The outer plastic has a certain hardness, impact resistance, friction resistance and a certain self-lubricating type.

Plastic coated injection material

Plastic coated injection material

Polyformaldehyde (POM), also known as steel, has excellent mechanical properties, high elastic modulus, high rigidity and surface hardness, small friction coefficient, wear resistance and self-lubrication excellence, second only to nylon but cheaper, good dimensional stability, can manufacture precision parts, suitable for making gears and bearings, etc., can also be used for pipeline devices.

Nylon (PA) is a kind of engineering plastic, PA6, PA66, PA610, PA1010 and other types, high mechanical strength, good toughness, high tensile and compressive strength, outstanding fatigue resistance, wear resistance, corrosion resistance, heat resistance, non-toxic, excellent electrical properties, often used in the manufacture of bearings and other structural components.

Polypropylene (PP) is the lightest of the resin materials, excellent mechanical properties, including tensile strength, compressive strength and hardness, outstanding rigidity and resistance to bending fatigue properties. Good chemical stability, in addition to strong oxidants, and most chemicals do not react, suitable for use in acid-base environment.

Polyethylene (PE) is a thermoplastic resin prepared by polymerization of ethylene monomer. The mechanical properties are general, the tensile strength is low, the creep resistance is not good, the impact resistance is good. Suitable for use in acid-base environment

Polyether ether ketone (PEEK) is an aromatic crystalline thermoplastic polymer material with high mechanical strength, high temperature resistance, impact resistance, flame retardant, acid and alkali resistance, hydrolysis resistance, wear resistance, fatigue resistance, radiation resistance and good electrical properties. Suitable for high temperature environment.

Polytetrafluoroethylene (PTFE) friction factor is the smallest, and when the load increases, the friction factor decreases accordingly, often add glass fiber, graphite, bronze powder and other performance indicators, high working temperature, with excellent corrosion resistance and chemical stability, but the mechanical strength is relatively low, often used with other materials composite, It is used to manufacture bearings that require high frictional properties and chemical stability.

Product Application

Product Application

Injection molding wheels have a wide range of uses, mainly used in the following fields :

Automotive : injection molded small wheels are widely used in the injection molding of automotive external parts, such as door handles, tire covers, ceilings, bumpers, windshield wipers and so on. These parts have excellent toughness, strength and anti-aging properties, not easy to deformation, strong durability, in line with the use of automotive external parts.

Electronic : injection molded small wheels are also widely used in the plastic shell of electronic products, keys, sockets and other parts. These parts have the characteristics of lightweight, good insulation, wear resistance, high temperature resistance, chemical corrosion resistance, etc., and are often used in the production of high-quality electronic products.

Medical device : injection molded small wheels are often used in the manufacture of disposable syringes, infusion sets, blood oxygen meters, electrocardiograph and other medical devices. These parts meet the requirements of medical materials, are non-toxic, odorless, and harmless, and can be customized to meet the requirements of different medical devices 1.

Toy : toy parts made of injection molded small wheels have the advantages of rich color, beautiful appearance, soft texture, non-toxic and tasteless, etc., which are commonly found in the fields of children's toys, plastic models and handicrafts.

Machinery and equipment : injection molded small wheels are suitable for the movement and transmission of various mechanical equipment, with the advantages of precise size and smooth surface, etc., can meet the basic requirements of mechanical equipment for wheels.

- Previous: Thrust ball bearing:51108

- Next: Custom Non-Standard Bearings

RELATED PRODUCTS