Basic Parameters

Basic ParametersThe UKF210 bearing is a key component widely used in the field of mechanical transmission. It belongs to the type of spherical outer race ball bearing with a housing. This design enables it to play an indispensable role in many devices. It can effectively support the rotating shaft and reduce friction to ensure the smooth operation of the mechanical system.

Structural Features

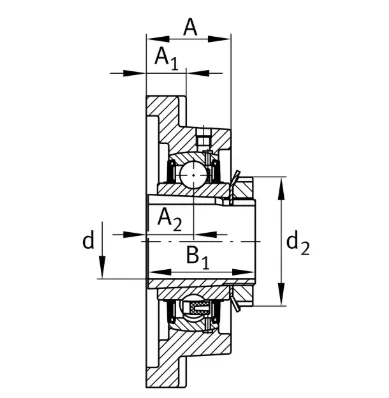

Structural FeaturesOuter spherical surface design

The outer surface of the outer ring of the UKF210 bearing is spherical. This outer spherical structure is one of its notable features. It can closely fit with a bearing housing with an inner spherical surface. This characteristic enables the bearing to self-align after installation and effectively compensate for coaxiality deviations caused by shaft deflection or installation errors. For example, in some equipment with long shaft transmissions, due to the self-weight of the shaft or the force during operation, the shaft may bend to a certain extent. The self-aligning function of the UKF210 bearing can well adapt to this situation and ensure good contact and normal operation between the bearing and the shaft.

Internal structure

Its interior is mainly composed of an inner ring, an outer ring, rolling elements, and a cage. The rolling elements are usually spherical and evenly distributed on the raceways between the inner ring and the outer ring. This structure enables the bearing to bear radial loads and to a certain extent, axial loads as well. The role of the cage is to separate the rolling elements, guide the rolling elements to move in a circular motion on the raceway, and can reduce the mutual collision and friction between the rolling elements, thereby reducing energy loss and improving the working efficiency of the bearing.

Dimensions

Inner diameter size

- The inner diameter size of UKF210 bearing is determined by the standard bearing code rules. In its code, the last two digits "10" represent the inner diameter. The specific calculation method is inner diameter = 10×5 = 50mm (when the last two digits of the basic bearing code are greater than or equal to 04, the inner diameter size = number ×5). This size is very important for determining the fit between the bearing and the shaft. A proper fit can ensure good centering and stable operation of the shaft in the bearing.

Outer diameter and width size

- In addition to the inner diameter size, the outer diameter and width size are also important parameters of the bearing. Although these sizes will vary slightly due to the design and manufacturing tolerances of different manufacturers, they are generally determined according to certain size series standards. These sizes determine the installation space and overall structural layout of the bearing in the equipment, ensuring that the bearing can be compatible with the surrounding mechanical parts without interference.

Materials and manufacturing processes

Materials and manufacturing processesMaterial Selection

- The UKF210 bearing mainly uses high-carbon chromium bearing steel as the basic material. This kind of steel contains an appropriate amount of chromium element. Chromium can improve the hardness and wear resistance of the steel, and at the same time enhance the corrosion resistance of the steel. In some special working environments, such as humid or moderately corrosive environments, the bearing surface may also use special coatings (such as chrome plating, nickel plating, etc.) or use stainless steel material to further improve its corrosion resistance.

Manufacturing Process

- In the manufacturing process, starting from the forging of raw materials, advanced processes are used to ensure the compactness and uniformity of the internal structure of the steel. The forged blank undergoes multiple high-precision processing procedures such as turning and grinding, and uses numerical control processing equipment to accurately control the size and shape. In the assembly link, professional assembly techniques and tools are used to ensure the correct installation of rolling elements and raceways and appropriate preload. Finally, through a strict inspection process, including various means such as size inspection, hardness inspection, and vibration inspection, it is ensured that each UKF210 bearing meets high-quality standards.

Product Application

Product Application Industrial Equipment

- In various industrial equipment, the UKF210 bearing is widely used. In the field of machine tools, it can be used as a spindle bearing or a feed shaft bearing, providing stable support for the rotation of cutting tools and the movement of worktables, and ensuring the machining accuracy of machine tools. In conveying equipment such as belt conveyors and chain conveyors, it is used to support rollers and ensure the smooth transportation of materials.

Automotive Industry

- In the wheel hub unit of automobiles, the UKF210 bearing can effectively support the rotation of wheels, bear various loads during vehicle driving, and ensure the rotational accuracy of wheels, improving the driving comfort and stability of vehicles. At the same time, it is also applied to rotating parts of auxiliary equipment of automobile engines, such as generators and water pumps, providing reliable support for the efficient operation of these devices.

Other Fields

- In agricultural machinery, the UKF210 bearing can be used in rotating parts such as the transmission shaft of tractors and the harvester. It can adapt to the complex working conditions in agricultural production. In wind power equipment, if the main shaft bearing of a wind turbine adopts UKF210, it can work stably in an environment with high wind speed and high load, providing a strong guarantee for wind power generation.

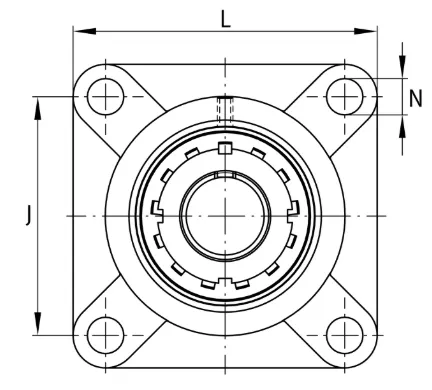

Product List

| Unit No. |

d |

A |

E |

F |

G |

L |

S |

Z |

B |

bolt size |

| UKF205 |

20 |

95 |

70 |

16 |

14 |

27 |

12 |

35,5 |

35 |

M10 |

| UKF206 |

25 |

108 |

83 |

18 |

14 |

31 |

12 |

39 |

38 |

M10 |

| UKF207 |

30 |

117 |

92 |

19 |

16 |

34 |

14 |

42,5 |

43 |

M12 |

| UKF208 |

35 |

130 |

102 |

21 |

16 |

36 |

16 |

46,5 |

46 |

M14 |

| UKF209 |

40 |

137 |

105 |

22 |

18 |

38 |

16 |

48,5 |

50 |

M14 |

| UKF210 |

45 |

143 |

111 |

22 |

18 |

40 |

16 |

50 |

55 |

M14 |

| UKF211 |

50 |

162 |

130 |

25 |

20 |

43 |

19 |

54,5 |

59 |

M16 |

| UKF212 |

55 |

175 |

143 |

29 |

20 |

48 |

19 |

61 |

62 |

M16 |

| UKF213 |

60 |

187 |

149 |

30 |

22 |

50 |

19 |

64 |

65 |

M16 |

| UKF215 |

65 |

200 |

159 |

34 |

22 |

56 |

19 |

71 |

73 |

M16 |

| UKF216 |

70 |

208 |

165 |

34 |

22 |

58 |

23 |

73,5 |

78 |

M20 |

| UKF217 |

75 |

220 |

175 |

36 |

24 |

63 |

23 |

77 |

82 |

M20 |

| UKF218 |

80 |

235 |

187 |

40 |

24 |

68 |

23 |

81,5 |

86 |

M20 |

Basic Parameters

Basic Parameters

Structural Features

Structural Features Materials and manufacturing processes

Materials and manufacturing processes Product Application

Product Application  Product List

Product List