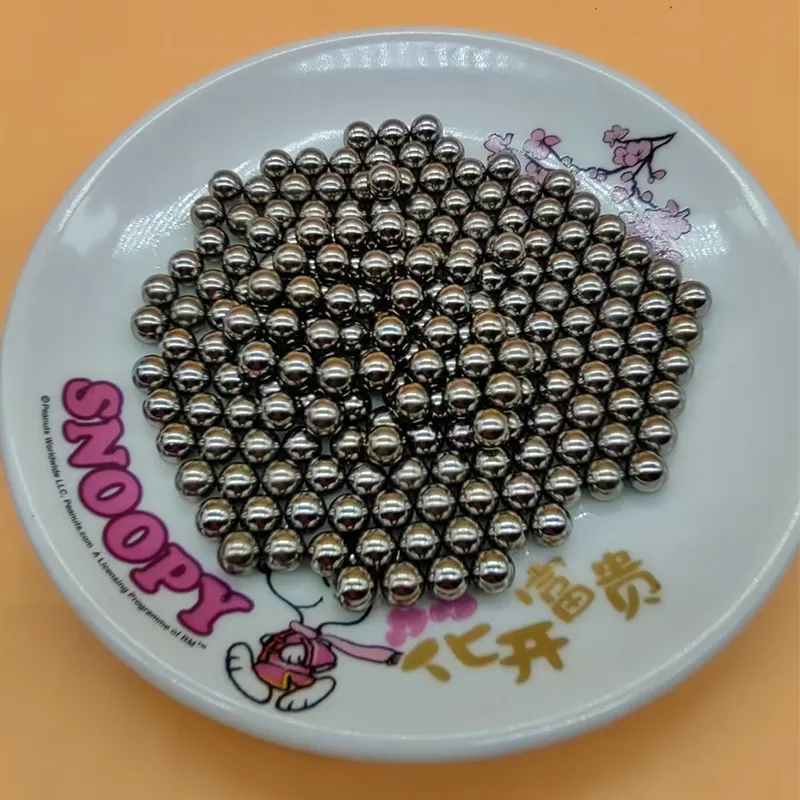

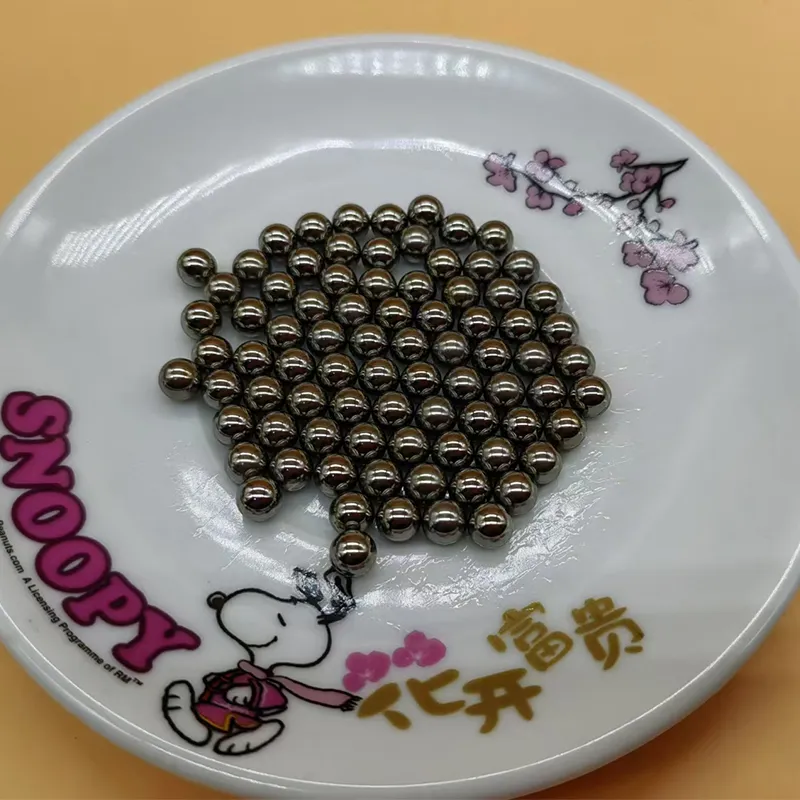

Bearing Steel Ball

Characteristics

Characteristics

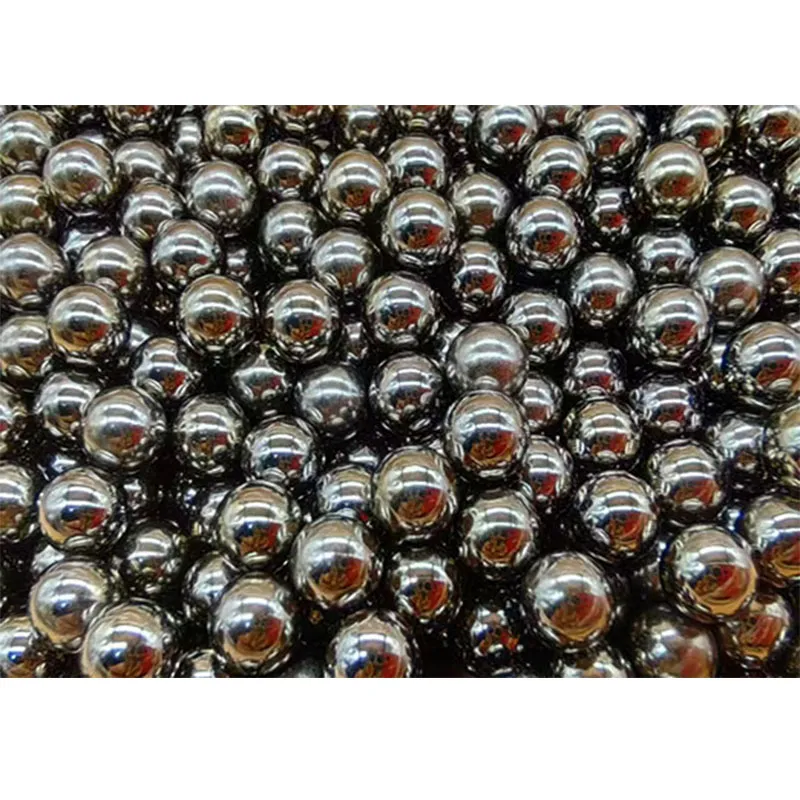

1. High precision: It has strict dimensional accuracy and roundness to ensure smooth running of bearings.

2. High hardness: can withstand greater pressure and friction, not easy to deformation and wear.

3. Good wear resistance: During long-term use, it can maintain good surface quality and extend the service life of bearings.

4. Good stability: stable and reliable performance in different working environments.

Material

Material

Mainly used bearing steel, such as GCr15. This kind of steel has the characteristics of high hardness, high wear resistance, good toughness and hardenability.

Level

Level

1. Generally divided into G10, G16, G20, G28, G40, G60, G100, G200, G500, G1000 and other different levels.

2. The higher the grade, the better the dimensional accuracy, roundness, surface roughness and other indicators of the steel ball.

Basic Parameters

Basic Parameters

1. Diameter: Common diameter specifications range from a few millimeters to tens of millimeters.

2. Hardness: Generally between HRC60-66.

3. Accuracy level: As mentioned above, different levels correspond to different accuracy requirements.

4. Surface roughness: usually in microns, the higher the grade, the smaller the surface roughness.

5. Material composition: mainly contains carbon, chromium, manganese, silicon and other elements, the composition ratio of different materials will be different.

- Previous: Bearing Set Sleeve And Release Sleeve

- Next: Bearing Ring

RELATED PRODUCTS