Basic Parameters

SAL

- “SAL” is usually an identification of a series of rod end bearings. It indicates that this is a specific structure and type of rod end bearing, used to connect connecting rods and other mechanical parts, realizing relative rotation and being able to bear certain axial and radial loads.

50

- The number “50” generally represents the main dimensional parameter of the bearing. In rod end bearings, this number is likely to refer to the inner diameter size of the bearing. For SAL50T/K, its inner diameter may be 50mm. The inner diameter is a key dimension of the bearing, which determines the diameter of the shaft that the bearing is adapted to.

T

- The letter “T” in the rod end bearing code may have multiple meanings. In common cases, it may indicate the thread type or structural feature of the bearing. For example, it may represent a specific thread specification (such as metric thread or inch thread), or indicate the special structural design inside the bearing for adapting to different installation methods and load directions.

/K

- “/K” is usually a supplementary code for bearings, used to represent some special technical requirements or design features. For example, it may indicate the lubrication method of the bearing (such as using special grease or having a special lubrication structure), the sealing structure (such as having a special sealing ring or dust cover), or some specific materials and heat treatment processes. These features enable the bearing to work better under specific working conditions.

Different bearing manufacturers may have slightly different definitions for the code. For the specific meaning, it is best to refer to the product manual or technical data of the manufacturer.

SAL50T/K

Product Features

Product FeaturesExcellent material selection

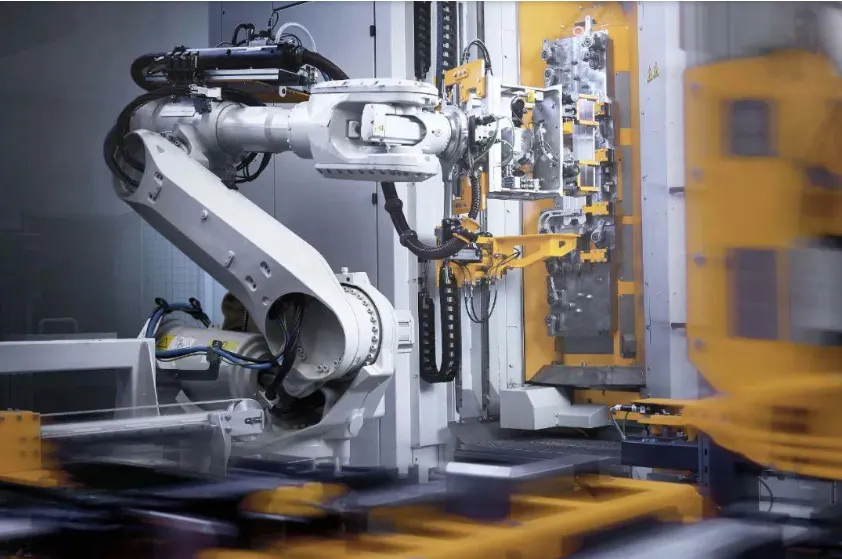

- The SAL50T/K rod end bearing uses high-quality bearing steel as the main raw material. This kind of steel has excellent hardness and toughness and can withstand large axial and radial loads. For example, in high-load industrial stamping equipment, our rod end bearings can work stably for a long time and are not prone to deformation or damage.

Surface treatment

- The product surface has undergone a special treatment process, including fine grinding and coating treatment. This not only makes the surface finish of the bearing reach a very high level, reduces the friction coefficient, but also enhances its corrosion resistance and is suitable for relatively harsh working environments such as wet mining equipment or outdoor construction machinery.

High-precision processing

- During the manufacturing process, we strictly control every process to ensure the dimensional accuracy of SAL50T/K. The machining tolerances of its inner diameter, outer diameter and spherical surface are all controlled within a very small range, which enables it to perfectly match the connecting rod and joint during installation and operation, realizing smooth and accurate rotational movement, thereby improving the operating efficiency and stability of the entire mechanical system.

Unique structural design

- This rod end bearing adopts an optimized internal structural design, which reasonably distributes the arrangement of balls or rollers, effectively disperses the load and reduces the phenomenon of local stress concentration. This design can extend the service life of the bearing and reduce the maintenance cost of equipment. For example, in long-term continuous operation of automated production line equipment, this structural advantage of SAL50T/K can significantly reduce the downtime of equipment.

Diverse installation methods

- The SAL50T/K rod end bearing is designed with multiple installation interfaces, which can be conveniently connected with different types of connecting rods and joints. Whether it is threaded connection, pin connection or other special connection methods, we can provide corresponding adaptation solutions to meet your needs in different mechanical designs.

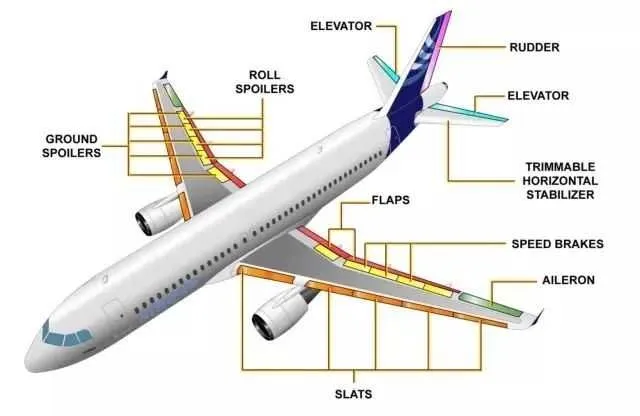

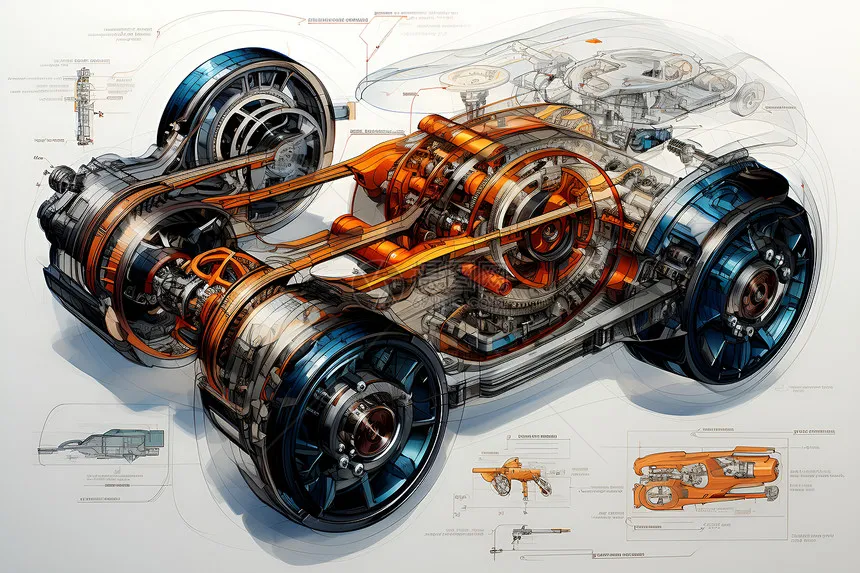

Multi-field application

- Due to its excellent performance, this rod end bearing is widely used in many industries. In the aerospace field, it can be used in the flight control system of aircraft to ensure the accuracy of flight operations; in the automotive manufacturing industry, it can be applied to the suspension system and steering system to provide a comfortable driving experience and reliable handling performance; in industrial automation equipment, it is an indispensable key component to ensure the efficient operation of the production line.

Quality Assurance and Service

Quality Assurance and ServiceStrict quality inspection

- Each SAL50T/K rod end bearing undergoes multiple quality inspection procedures before leaving the factory, including dimensional accuracy inspection, load testing, rotational accuracy testing, etc. Only products that fully meet our high-standard quality requirements will be delivered to you.

Professional after-sales service

- We have a professional after-sales service team that is always ready to answer your questions about product use and maintenance. If any quality problems occur during use, we will provide you with solutions in a timely manner to ensure that your production and operation are not affected.

The SAL50T/K rod end bearing, with its high-quality materials, precise manufacturing, wide adaptability, and reliable quality assurance, is an ideal choice for you in mechanical design and equipment maintenance. We believe that choosing our rod end bearing will bring higher efficiency and lower cost to your project.

If you have any further questions or need detailed product information, please feel free to contact us.

Product List

| Bearing No. |

Dimensions (mm) |

Basic Load Rating (N) |

Weight |

| ISO |

GOST |

d |

D |

B |

Dyn. C |

Stat. C0 |

(kg) |

| SAL10 T/K |

SAL10 T/K |

10 |

- |

14 |

14.5 |

18 |

0.055 |

| SAL12 T/K |

SAL12 T/K |

12 |

- |

16 |

17 |

24 |

0.085 |

| SAL12-1 T/K |

SAL12-1 T/K |

12 |

- |

16 |

17 |

24 |

0.085 |

| SAL14 T/K |

SAL14 T/K |

14 |

- |

19 |

24 |

31 |

0.140 |

| SAL16 T/K |

SAL16 T/K |

16 |

- |

21 |

28.5 |

39 |

0.210 |

| SAL16-1 T/K |

SAL16-1 T/K |

16 |

- |

21 |

28.5 |

39 |

0.210 |

| SAL18 T/K |

SAL18 T/K |

18 |

- |

23 |

42.5 |

47.5 |

0.280 |

| SAL20 T/K |

SAL20 T/K |

20 |

- |

25 |

42.5 |

57 |

0.380 |

| SAL22 T/K |

SAL22 T/K |

22 |

- |

28 |

57 |

68 |

0.480 |

| SAL25 T/K |

SAL25 T/K |

25 |

- |

31 |

68 |

85 |

0.640 |

| SAL28 T/K |

SAL28 T/K |

28 |

- |

35 |

86 |

107 |

0.800 |

| SAL30 T/K |

SAL30 T/K |

30 |

- |

37 |

88 |

114 |

1.100 |

| SAL35 T/K |

SAL35 T/K |

35 |

- |

43 |

- |

- |

1.640 |

| SAL40 T/K |

SAL40 T/K |

40 |

- |

49 |

- |

- |

2.300 |

| SAL5 T/K |

SAL5 T/K |

5 |

- |

8 |

5.7 |

6 |

0.013 |

| SAL50 T/K |

SAL50 T/K |

50 |

- |

60 |

- |

- |

4.800 |

| SAL6 T/K |

SAL6 T/K |

6 |

- |

9 |

7.2 |

7.65 |

0.020 |

| SAL8 T/K |

SAL8 T/K |

8 |

- |

12 |

11.6 |

12.9 |

0.038 |

Basic Parameters

Basic Parameters Product Features

Product Features Quality Assurance and Service

Quality Assurance and Service Product List

Product List