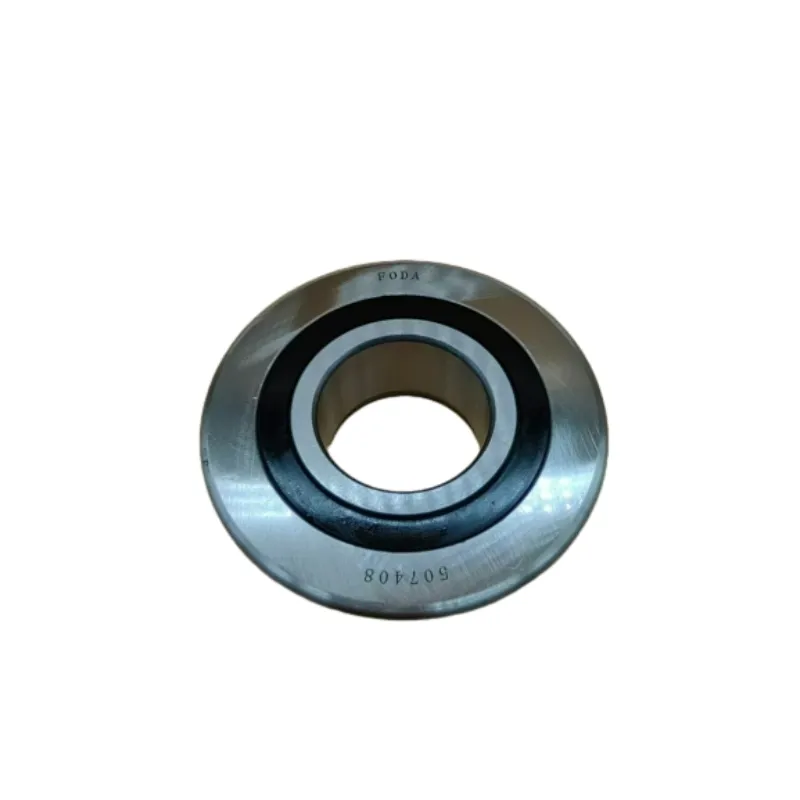

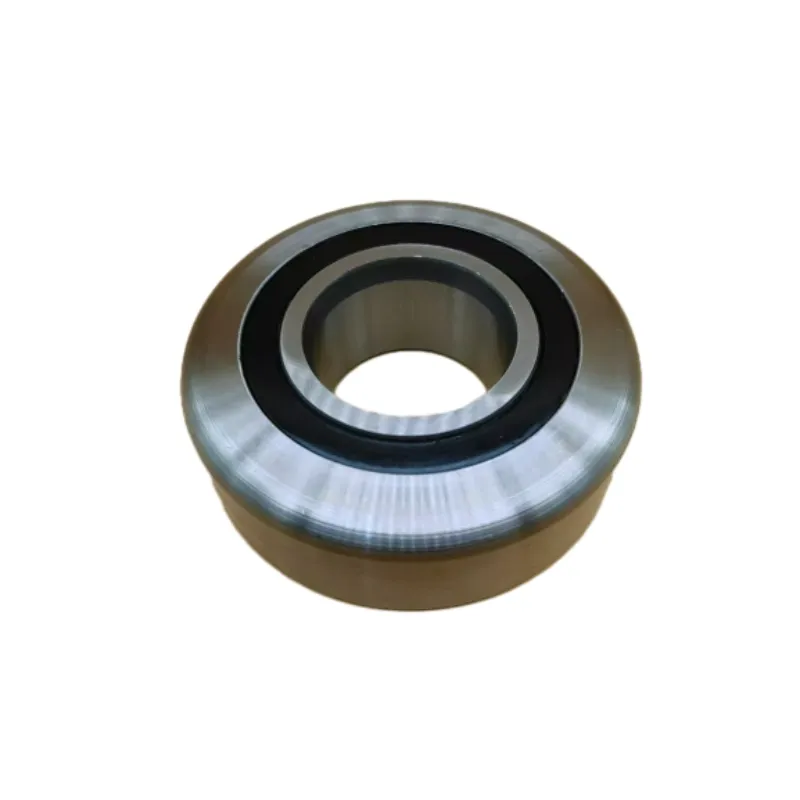

Forklift Bearings - Specialized Components For Forklifts

Characteristics

Characteristics

1. Strong carrying capacity: It can withstand the large load generated by the forklift when carrying heavy objects.

2. Wear resistance: Adapt to the working environment of forklift truck frequent start and stop and heavy duty operation, with a long service life.

3. Good stability: Ensure the stable operation of all parts of the forklift during operation to reduce shaking and vibration.

4. Good sealing: effectively prevent dust, impurities and moisture from entering the bearing inside, protect the bearing from damage.

Classification

Classification

1. Hub bearings: used for the support and rotation of forklift wheels.

2. Steering bearings: They play a key role in the steering system of forklift trucks.

3. Transmission system bearings: such as transmission bearings, to ensure the transmission of power.

Basic Parameters

Basic Parameters

1. Inner diameter, outer diameter and width: determine the installation size of the bearing, and need to match the corresponding part of the forklift.

2. Rated dynamic load and rated static load: reflects the dynamic and static load that the bearing can withstand.

3. Limit speed: indicates the maximum speed allowed by the bearing under specific working conditions.

The Working Principle

The Working Principle

By rolling between the inner and outer rings of the rolling body (such as balls, rollers, etc.), the sliding friction is transformed into rolling friction, thereby reducing the friction resistance and realizing the smooth rotation and support of the parts. When the forklift is operating, the bearings bear loads from all directions and transfer them to the frame or other support structure of the forklift.

Application Fields

Application Fields

1. Logistics warehousing: Handling goods in the warehouse to improve logistics efficiency.

2. Manufacturing: used for handling and loading of materials in the factory.

3. Port terminal: Handling containers and cargo.

4. Construction site: Transportation of construction materials, etc.

- Previous: Large Bearings-Slewing Support Bearings

- Next: Knuckle Bearing Is A Spherical Plain Bearing

RELATED PRODUCTS