Dec . 12, 2024 11:14 Back to list

Crossed Roller Bearings: The Excellent Choice for Precise Transmission in Gear Reducers

In the innovative development process of gear reducers, crossed roller bearings are like a shining star, shining brightly in the vast sky of industrial transmission with their unique advantages and achieving extremely wide applications in the field of gear reducers.

The unique structural design of crossed roller bearings is the core reason why they are favored in gear reducers. It consists of an inner ring, an outer ring, and cylindrical rollers arranged in a crossed manner between them. Compared with traditional bearings, this special arrangement can significantly improve the radial and axial load-bearing capacities as well as the rotational accuracy within a very limited space. In precision planetary gear reducers where the space layout is compact and the requirements for precision and load-bearing capacity are extremely high, crossed roller bearings, thanks to their compact structural design, can achieve powerful supporting functions in a relatively small volume. Whether dealing with the radial centrifugal force generated during high-speed rotation or with the axial thrust under complex working conditions, they can handle it with ease, ensuring that each planetary gear in the gear reducer operates stably on a high-precision track, thus accurately transmitting power and laying a solid foundation for the efficient operation of precision equipment such as CNC machine tools and industrial robots.

The extremely high rotational accuracy is another significant advantage that crossed roller bearings bring to gear reducers. In high-precision harmonic gear reducers, the meshing accuracy between the flexspline and the circular spline directly affects the transmission error and overall performance of the gear reducer. The close fit between the precision rollers of the crossed roller bearings and the raceways keeps the radial runout and axial displacement within a micrometer level or even smaller. When the gear reducer is in operation, this outstanding rotational accuracy enables the flexspline to interact with the circular spline in an almost perfect trajectory, effectively reducing the backlash and vibration during the transmission process and greatly improving the positioning accuracy and repeat positioning accuracy of the harmonic gear reducer. This is of vital importance for equipment in fields such as semiconductor manufacturing and optical instrument processing, because even the slightest transmission error may lead to the scrapping of products or a serious decline in performance.

crossed roller bearings also possess excellent rigidity and anti-overturning moment capabilities. In heavy-duty industrial gear reducers, such as those used in metallurgical equipment and mining machinery, the equipment often faces huge impact loads, frequent starts and stops, and complex changes in force. The rigid structure of crossed roller bearings enables them to effectively resist the overturning moment generated by external forces while withstanding high loads, ensuring that the shafting of the gear reducer always maintains a stable geometric position relationship. Even under extremely harsh working conditions, they can act like a solid fortress, safeguarding the core transmission components of the gear reducer, preventing equipment failures caused by bearing deformation or displacement, and thus ensuring the continuity and reliability of the entire industrial production process and protecting the stable production and operation of enterprises.

In terms of the operational stability and service life of gear reducers, crossed roller bearings also perform excellently. Their good lubrication performance and sealing design effectively reduce friction losses and the intrusion of impurities. High-quality grease can form a stable lubricating film between the rollers and the raceways, reducing the friction coefficient and heat generation, and further reducing the wear rate of the bearings. And the precise sealing structure serves as a reliable defense line, blocking dust, moisture, and other tiny particles from entering the interior of the bearings, avoiding scratches or corrosion on the bearing surfaces caused by these impurities, and prolonging the maintenance cycle and service life of the bearings. In the gear reducers on long-term continuously operating automated production lines, the advantages of stability and durability of crossed roller bearings are fully demonstrated, reducing the downtime for equipment maintenance, improving production efficiency, and saving a large amount of operating costs for enterprises.

The wide application of crossed roller bearings in the field of gear reducers is undoubtedly a vivid portrayal of the progress of industrial technology. With their many advantages such as compact structure, high rotational accuracy, strong rigidity, and good stability, they meet the increasingly stringent performance requirements of modern industry for gear reducers and play an indispensable and crucial role in promoting the development of mechanical equipment in various industries towards higher precision, higher efficiency, and more reliable operation, making them a well-deserved excellent choice in the field of precise transmission of gear reducers.

|

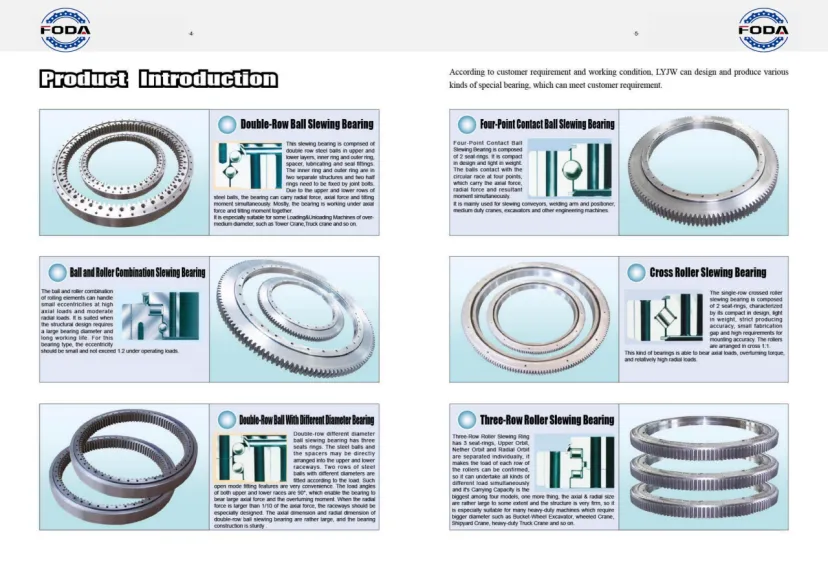

Classification of Slewing Bearing |

Characteristics |

Applicable Reducer Types |

|

Single-row Four-point Contact Ball Slewing Bearing |

Can withstand axial force, radial force and overturning moment |

Small and medium-sized general-purpose reducers |

|

Double-row Different Diameter Ball Slewing Bearing |

Has a large bearing capacity and can withstand a large overturning moment |

Medium-sized industrial reducers |

|

Single-row Crossed Roller Slewing Bearing |

Has high precision and rigidity |

High-precision CNC reducers |

|

Three-row Roller Slewing Bearing |

Has an extremely strong bearing capacity and can withstand huge axial force, radial force and overturning moment |

Heavy-duty mining machinery reducers |

-

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!

NewsApr.28,2025

-

Notice of May Day Labor Day Holiday |

NewsApr.24,2025

-

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!

NewsApr.24,2025

-

Revolutionary 10 - Meter Travel Linear Motors Unveiled

NewsApr.24,2025

-

Linear Module Dual-station Multi-mover Guided Dispensing: A Reliable Helper in Production

NewsApr.22,2025

-

Stop Worrying About Item Transferring! Linear Modules to the Rescue!

NewsApr.18,2025

Products categories

-

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More -

Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More

Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More -

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More

Manufacturing & Processing