Nov . 13, 2025 00:00 Back to list

Zhuhai Air Show: The Bearing Power Behind Aerospace

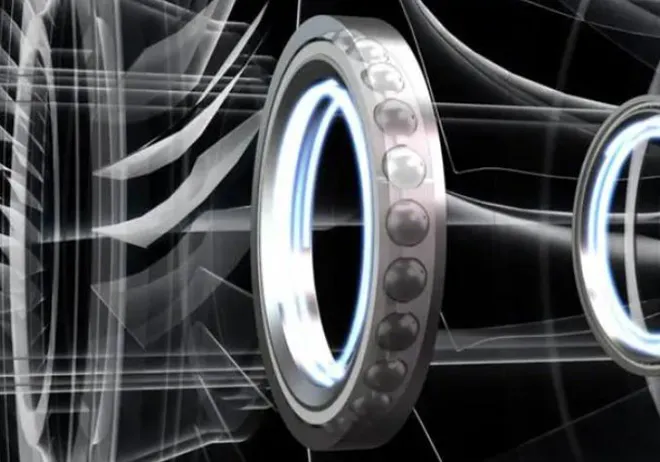

At the site of the Zhuhai Air Show, new fighter jets pierced through the sky and whizzed past, their vigorous posture and advanced performance made every spectator's blood boil. When people marvel at these high-tech achievements in the field of aerospace, have you ever thought that behind every great achievement, there is a key precision accessory - the bearing, which is like the cornerstone of a building. Although it is not eye-catching, it plays a decisive role.

As the crown jewel of modern science and technology, the complexity and advancement of aerospace technology require that every component must achieve the ultimate performance. From the wings of the aircraft to the engine, from the shell of the spacecraft to the internal control system, every detail is related to the safety and performance of the entire system. And bearings, as a key support component for mechanical operation, are even more indispensable in the aerospace field.

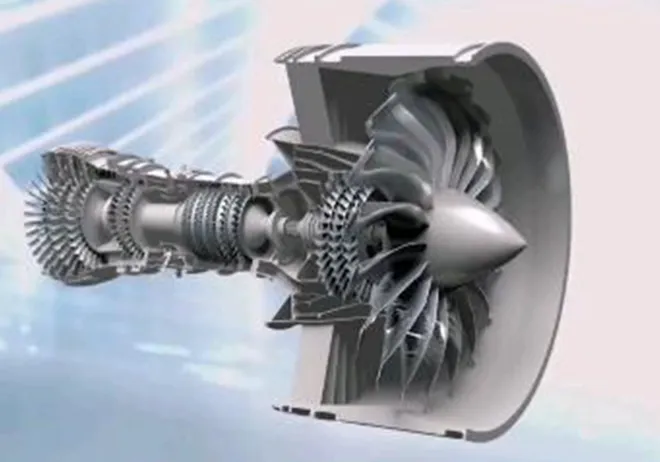

In the field of aero-engines, the importance of bearings is self-evident. Aeroengines are the "heart" of aircraft, and bearings are the "joints" in this "heart", which bear huge axial and radial loads, ensuring that the high-speed rotating parts of the engine can operate smoothly and efficiently. For example, in turbofan engines, spindle bearings need to work under extreme conditions of high temperature, high speed and high load. When the engine is working, the spindle speed can reach tens of thousands of revolutions per minute, and the temperature can climb to several hundred degrees. Bearings not only have to withstand huge centrifugal and friction forces, but also ensure that fatigue wear and overheating deformation do not occur during long-term operation. Once the bearing fails, even the slightest flaw can cause the engine's vibration to increase, efficiency to decrease, and even lead to catastrophic shutdown accidents. Therefore, aero-engine bearings must use high-performance special materials, such as superalloys, ceramics, etc., and undergo precise processing techniques and strict quality inspection to ensure that they have excellent properties such as high strength, high hardness, high temperature resistance, wear resistance, and low friction coefficient.

In addition to the engine, the landing gear system of an aircraft also relies on the support of bearings. The landing gear bears the huge impact force during the takeoff and landing of the aircraft, and the bearings are responsible for ensuring the ease of retraction of the landing gear, ensuring the stability and safety of the aircraft during the ground taxi and takeoff and landing. These bearings need to have high load-bearing capacity, good impact resistance and corrosion resistance to cope with the complex and changeable airport environment and frequent takeoff and landing operations.

In the flight control system, bearings also play a key role. The rudder surface control bearing is installed in the control mechanism of various rudder surfaces of the aircraft (such as elevators, rudders, ailerons, etc.), and is used to connect the rudder surface with the joystick or transmission mechanism. When the pilot operates the flight control device, the rudder surface control bearing enables the rudder surface to rotate accurately and flexibly, thereby changing the flight attitude of the aircraft, such as pitch, yaw and roll. It requires extremely high accuracy and reliability, and any minor lag or failure may affect flight safety. The booster bearing is in the booster of the flight control system, helping the pilot to operate the rudder surface more easily, and improving the efficiency and comfort of flight control by reducing the handling force. These bearings need to have a low coefficient of friction and high reliability to ensure that the booster can function properly, provide the pilot with stable and accurate control force feedback, and ensure the sensitivity and reliability of the flight control system.

The following is a detailed description of the bearings used in different parts of the aircraft:

|

Aircraft Part |

Bearing Type |

Function Description |

|

Aero - engine - spine |

Spindle bearing |

Support the main shaft of the engine, withstand huge axial and radial loads, ensure the stable transmission of engine power, and enable components such as fans, compressors, and turbines to work together. |

|

Aero - engine - Turbine |

Turbine bearing |

Support turbine rotors under high - temperature, high - speed, and high - load conditions, convert gas energy into mechanical energy, drive the engine to generate thrust, and have extremely high requirements for materials and craftsmanship. |

|

Aero - engine - Gearbox |

Gearbox bearing |

Support the rotation of the gear shaft, ensure the precision and stability of gear transmission, reduce friction and energy loss, and ensure the normal operation of engine accessories. |

|

Landing gear system - Main wheel |

Main wheel bearing |

Withstand the weight, impact force, and friction of the aircraft during take - off, landing, and taxiing, ensure the flexible rotation of the main wheel, and ensure the smooth retraction and release of the landing gear. |

|

Landing gear system - Nose wheel |

Nose wheel bearing |

Realize the steering function of the landing gear, withstand lateral force and friction, and ensure that the pilot can accurately control the taxiing direction of the aircraft. |

|

Flight control system - Cockpit operation/ rudder surface maneuering |

Cockpit operation bearing |

Connect the cockpit surface with the control mechanism, enable the cockpit surface to rotate accurately and flexibly, change the flight attitude of the aircraft, and have extremely high requirements for precision and reliability. |

|

Flight control system - Booster |

Booster bearing |

Help the pilot easily control the cockpit surface, reduce control force, improve flight control efficiency and comfort, and need to have low friction and high reliability |

Every aerospace high-tech achievement at the Zhuhai Air Show is the crystallization of the silent efforts of many bearing manufacturers behind the scenes. It is these seemingly ordinary but crucial bearings that play an irreplaceable role in their respective positions, which together support the magnificent edifice of aerospace technology and push mankind towards the vast universe. When we look up at the aircraft soaring in the sky and the spacecraft shuttling between the stars again, we should not only admire the high-tech of aerospace in our hearts, but also pay tribute to these silently dedicated bearings. Although they are small, they contain huge energy and are a solid guarantee for the continuous development of the aerospace industry.

-

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!

NewsApr.28,2025

-

Notice of May Day Labor Day Holiday |

NewsApr.24,2025

-

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!

NewsApr.24,2025

-

Revolutionary 10 - Meter Travel Linear Motors Unveiled

NewsApr.24,2025

-

Linear Module Dual-station Multi-mover Guided Dispensing: A Reliable Helper in Production

NewsApr.22,2025

-

Stop Worrying About Item Transferring! Linear Modules to the Rescue!

NewsApr.18,2025

Products categories

-

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More -

Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More

Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More -

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More

Manufacturing & Processing