Dec . 20, 2024 00:00 Back to list

Spherical Roller Bearings: The Core Supporting Force in Heavy Machinery

In the vast field of heavy machinery, spherical roller bearings are like a bright and solid pearl, playing an irreplaceable and crucial role.

Taking heavy-duty gear reducers as an example, spherical roller bearings are the key to ensuring their stable operation. Inside the gear reducer, the gears rotating at high speed mesh with each other and transmit huge torque. Thanks to their unique structural design, spherical roller bearings can accurately bear radial loads from all directions as well as a certain amount of axial loads. For instance, in the large gear reducers with steel rolling mills in steel plants, spherical roller bearings have to work under heavy loads and impact loads for a long time. The double-row roller structure evenly distributes the loads, effectively preventing local wear or deformation between the shaft and the bearing housing due to uneven force. Meanwhile, their excellent self-aligning performance enables them to maintain a good contact state even in cases of equipment installation errors, shaft deflection deformation, or slight displacements of the shafting caused by thermal expansion and contraction, ensuring the smoothness and efficiency of power transmission. This not only significantly reduces the failure rate of the gear reducer and extends the service life of the equipment but also guarantees the continuous and stable operation of the entire steel rolling production line, avoiding huge economic losses caused by equipment shutdowns for maintenance.

In the field of mining machinery and equipment, spherical roller bearings are faced with extremely harsh working environment tests. In ore crushers, when huge ores are forcefully crushed, strong vibrations and impacts are generated. spherical roller bearings must possess strong impact resistance and high load-bearing capacity. They are like a resolute warrior, firmly supporting the main shaft of the crusher to ensure the smooth progress of the crushing process. In the driving devices of mine conveyor belts, spherical roller bearings need to adapt to frequent starts and stops, speed changes, and different degrees of material impacts. Their outstanding self-aligning characteristics can automatically compensate for shaft misalignment problems caused by changes in conveyor belt tension, installation deviations, and other factors, ensuring the stable rotation of the driving drums and enabling the conveyor belts to continuously transport ores from the mining area to the processing site, maintaining the efficient operation of mining operations.

For other types of heavy machinery, such as large cranes and cement rotary kilns, spherical roller bearings are also indispensable core components. In the hoisting and slewing mechanisms of large cranes, spherical roller bearings bear huge lifting loads and complex dynamic forces. They play a decisive role in ensuring the smoothness and accuracy when the crane lifts heavy objects, preventing serious safety accidents such as heavy objects falling due to bearing failures. In cement rotary kilns, high temperature, heavy load, and the slow rotation of the kiln body are typical working conditions. spherical roller bearings not only have to bear the weight of the kiln body and the materials but also adapt to thermal expansion deformation in a high-temperature environment. With their excellent high-temperature resistance and reliable load-bearing capacity, they ensure the continuous and stable progress of the cement clinker firing process, providing a solid foundation for the production of building materials industry.

The application of spherical roller bearings in the field of heavy machinery is a model of the close combination of engineering technology and mechanical manufacturing. With their outstanding performance characteristics, they provide stable support, accurate power transmission, and reliable operation guarantee for heavy machinery, becoming the core source of strength for promoting the continuous development and progress of the heavy industry.

|

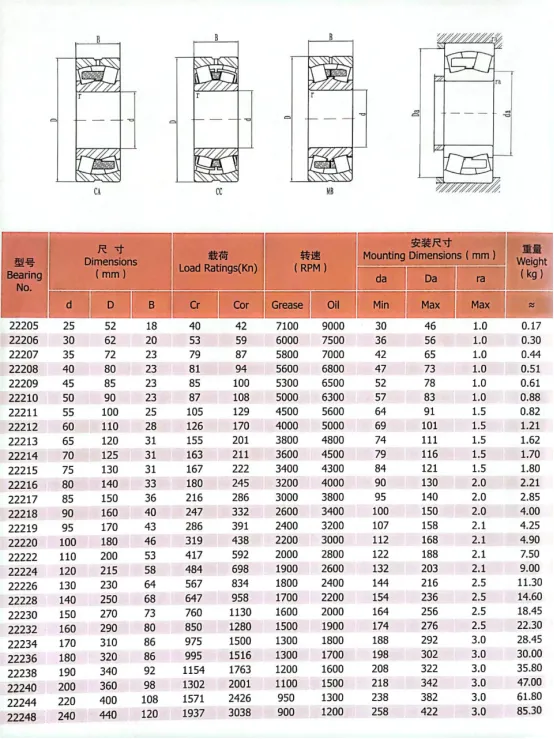

Model |

Main Dimensions (mm) |

Features |

Application Scenarios |

|

22210 |

Bore 50 × OD 90 × Width 23 |

Double-row rollers with excellent self-aligning ability, capable of handling heavy radial loads and moderate axial loads. |

Heavy-duty gear reducers, mining equipment, and power devices subject to vibrations and shock loads. |

|

22312 |

Bore 60 × OD 130 × Width 46 |

Wider raceways and more rollers increase load capacity and resistance to deformation. |

Used in high-load gear reducer transmission shafts, paper machinery, and lifting equipment. |

|

23120 |

Bore 100 × OD 165 × Width 52 |

Suitable for medium to high-speed operations, can handle greater radial loads, and has strong misalignment tolerance. |

Industrial gear reducers, wind power equipment, and large machinery as main bearing components. |

|

23222 |

Bore 110 × OD 200 × Width 69 |

Large rollers and high-precision design enhance load capacity and durability, ideal for low-speed heavy loads. |

Mainly used in cement plants, metallurgical equipment, and high-power gear reducers. |

|

24024 |

Bore 120 × OD 180 × Width 60 |

High impact resistance and wear resistance, suitable for high-temperature and high-pressure conditions with excellent self-aligning capability. |

Found in metallurgical reducers, petrochemical equipment, and vibrating screens operating in harsh environments. |

|

24126 |

Bore 130 × OD 210 × Width 80 |

Wide roller design improves lubrication and heat dissipation, allowing for long-term operation at higher speeds. |

High-speed reducers, motor transmission systems, and large machinery shafts. |

-

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!

NewsApr.28,2025

-

Notice of May Day Labor Day Holiday |

NewsApr.24,2025

-

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!

NewsApr.24,2025

-

Revolutionary 10 - Meter Travel Linear Motors Unveiled

NewsApr.24,2025

-

Linear Module Dual-station Multi-mover Guided Dispensing: A Reliable Helper in Production

NewsApr.22,2025

-

Stop Worrying About Item Transferring! Linear Modules to the Rescue!

NewsApr.18,2025

Products categories

-

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More -

Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More

Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More -

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More

Manufacturing & Processing