Dec . 18, 2024 08:00 Back to list

The Precision Grades of cylindrical roller bearings: The Application Principles of

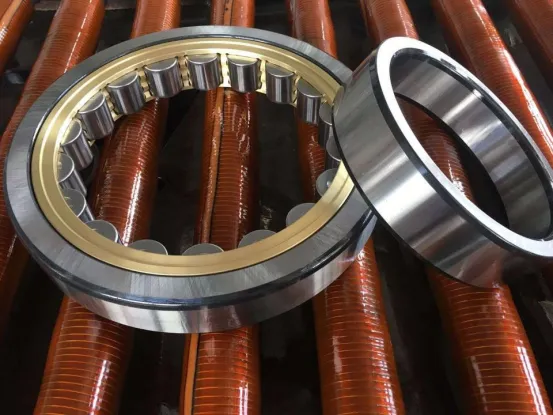

In the precise operation system of gear reducers, the precision grades of cylindrical roller bearings are like a fine ruler, which deeply affects the performance and operation quality of the equipment. Although there is only a slight difference between the P5 and P6 precision grades, they present distinct application scenarios in the world of gear reducers.

Cylindrical roller bearings with the P6 precision grade have a relatively balanced performance and play an important role in many general-purpose gear reducers. These gear reducers are widely used in general industrial production scenarios, such as the gear reducers for driving conveyor belts in ordinary machinery manufacturing workshops and the transmission gear reducers in simple material handling equipment. In these scenarios, the P6 precision bearings can effectively meet the equipment's requirements for basic rotational speed, load-bearing capacity, and operation stability. Although the indexes such as radial runout, axial runout, and rotational accuracy of these bearings are not as strict as those of the P5 grade, they are sufficient to handle the power transmission and load support under normal working conditions. With a relatively affordable cost, they provide reliable transmission guarantees for a large number of basic industrial productions, just like a craftsman who works quietly. Although they do not pursue extreme precision, they can steadily transmit power in place, ensuring the smooth operation of the production line and helping numerous small and medium-sized enterprises carry out production activities in an orderly manner in their respective fields.

On the other hand, the cylindrical roller bearings with the P5 precision grade are like a master who always strives for perfection and are specially designed for gear reducers with higher requirements for precision and performance. The P5 precision bearings shine brightly in the spindle gear reducers of high-precision CNC machining centers. In the CNC machining process, the cutting precision between the cutting tool and the workpiece is measured in micrometers or even smaller units, and any slight deviation may lead to the scrapping of products. At this time, the P5 precision bearings, relying on their excellent control of radial runout (usually within a smaller micrometer range), can raise the rotational accuracy of the spindle to a new level, thus ensuring that the cutting tool's trajectory is accurate when rotating at high speed for cutting, and the machined parts have a high surface finish and small dimensional tolerances, meeting the strict requirements for the high precision of parts in fields such as aerospace and high-end mold manufacturing. Similarly, the P5 precision bearings are also the top choice for the gear reducers in precision robot joints. The motion accuracy and repeatability of robots are directly related to their work efficiency and operation quality. The P5 precision bearings can effectively reduce the motion errors at the joints, enabling the robot's arms to move precisely in complex spatial trajectories. Whether it is the grasping and placing of tiny parts on a precision assembly line or the positioning and scanning actions in high-precision measuring equipment, all these operations rely on the high-precision support and stable transmission provided by the P5 precision cylindrical roller bearings.

From the perspective of the manufacturing process, the production of cylindrical roller bearings with the P5 precision grade requires stricter processing control and inspection procedures. From the careful selection of raw materials to the meticulous control of each processing procedure, and then to the high-precision inspection of the final products, every link involves more technology and efforts. For example, during the processing of rollers, the requirements for roundness, cylindricity, and surface roughness are more stringent than those of the P6 grade. More advanced processing equipment and technological means, such as high-precision grinding equipment and ultra-precision polishing processes, need to be adopted to ensure that the shape accuracy and surface quality of the rollers can meet the high standards of the P5 precision grade. In the assembly process of the bearings, it also needs to be carried out in a cleaner environment with constant temperature and humidity, and assembly workers need to have higher professional skills and operational experience. More precise assembly tools and measuring instruments are used to accurately adjust key parameters such as the clearance and preload of the bearings, so as to ensure that the bearings can meet all the performance indicators specified by the P5 precision grade after assembly.

In the actual selection and application of gear reducers, we must thoroughly consider various factors such as the working requirements of the equipment, the operating environment, and the cost budget. For those application scenarios of gear reducers where the precision requirements are not extremely high, cost control is relatively strict, and the operating conditions are relatively stable, the cylindrical roller bearings with the P5 precision grade are undoubtedly an economical and practical choice. When the equipment is in critical application fields with high-precision machining, high dynamic response, and extremely high requirements for operation reliability, the cylindrical roller bearings with the P5 precision grade stand out with their outstanding performance advantages and become the core components to ensure the efficient and accurate operation of the equipment. Whether they are cylindrical roller bearings with the P5 or P6 precision grade, they both play important roles on the stage of gear reducers and jointly promote the continuous development and progress of the industrial transmission field in the direction of diversification and high precision.

|

FODA BEARING |

Radial Runout (Max) |

Axial Runout (Max) |

Notes |

|

NU205 |

8 µm (0.008 mm) |

6 µm (0.006 mm) |

Radial runout refers to outer ring |

|

NJ210 |

10 µm (0.010 mm) |

8 µm (0.008 mm) |

Radial runout refers to outer ring |

|

NUP208 |

9 µm (0.009 mm) |

7 µm (0.007 mm) |

Radial runout refers to outer ring |

What is the axial runout and radial runout of the P6 grade of the above bearings? By comparison, you can understand the impact of the precision level of the bearing on the reducer.

|

FODA BEARING |

Radial Runout (Max) |

Axial Runout (Max) |

Notes |

|

NU205 |

12 µm (0.012 mm) |

8 µm (0.008 mm) |

Radial runout refers to outer ring |

|

NJ210 |

15 µm (0.015 mm) |

10 µm (0.010 mm) |

Radial runout refers to outer ring |

|

NUP208 |

13 µm (0.013 mm) |

9 µm (0.009 mm) |

Radial runout refers to outer ring |

-

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!

NewsApr.28,2025

-

Notice of May Day Labor Day Holiday |

NewsApr.24,2025

-

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!

NewsApr.24,2025

-

Revolutionary 10 - Meter Travel Linear Motors Unveiled

NewsApr.24,2025

-

Linear Module Dual-station Multi-mover Guided Dispensing: A Reliable Helper in Production

NewsApr.22,2025

-

Stop Worrying About Item Transferring! Linear Modules to the Rescue!

NewsApr.18,2025

Products categories

-

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More

Double Threaded Screw Slide: Achieving an Astounding Precision of 0.01mm while Bearing 100kg!Double thread screw slide # high precision # high loadRead More -

Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More

Notice of May Day Labor Day Holiday |Notice of May Day Labor Day Holiday | Grateful for Your Company, Looking Forward to New Achievements TogetherRead More -

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More

Lightning - Fast 90° Rotation and Pick - up in 6 Seconds!In the fast - paced race of industrial production, efficiency is the core of competitiveneRead More

Manufacturing & Processing