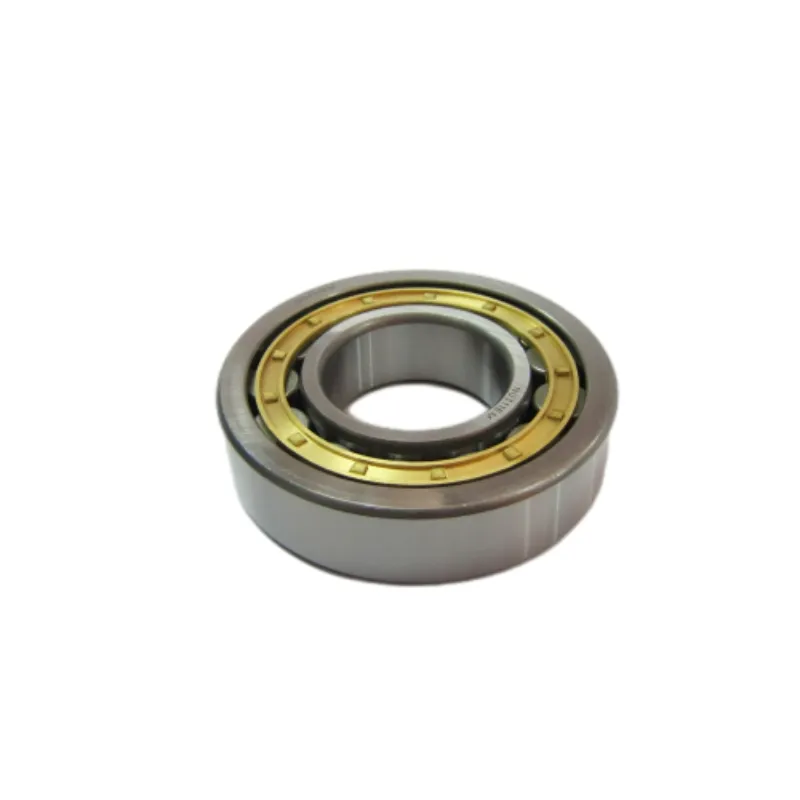

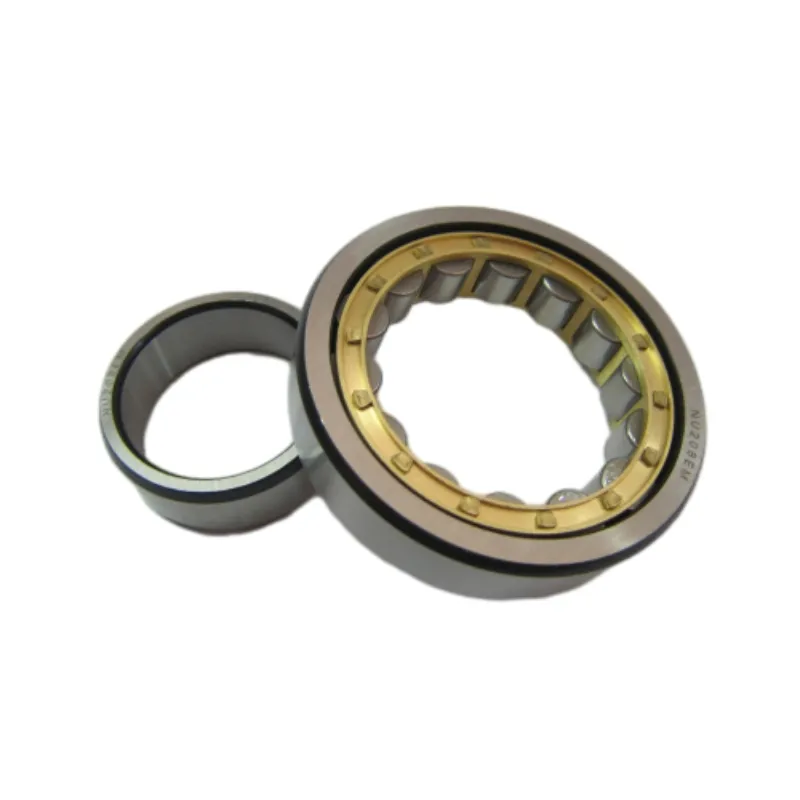

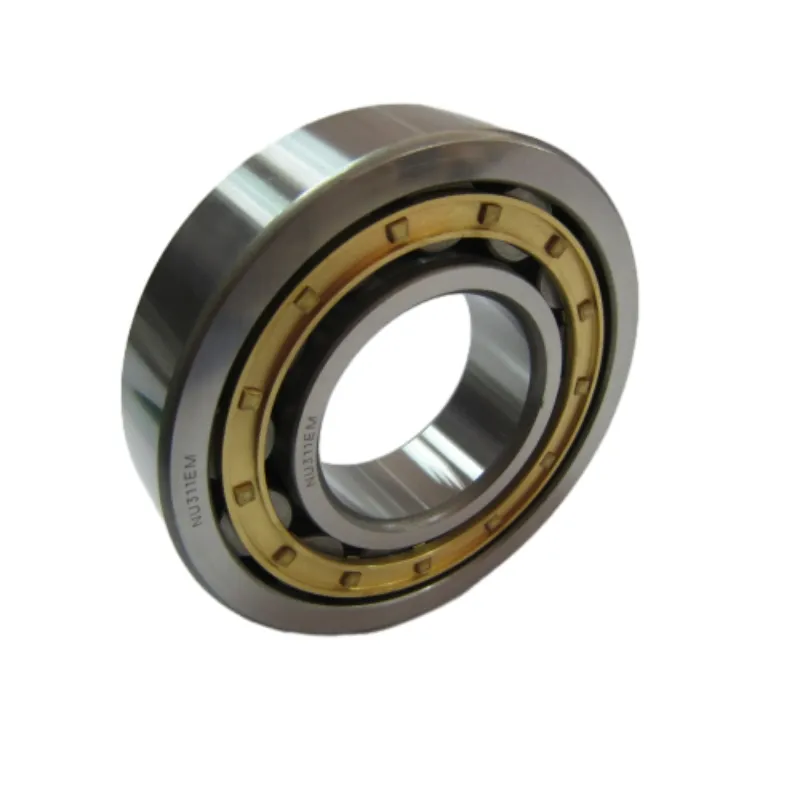

Cylindrical Roller Bearing

Characteristics

Characteristics

1. High bearing capacity: cylindrical rollers and raceways are in line contact and can withstand large radial loads.

2. High accuracy: it can provide high rotation accuracy and low vibration noise.

3. Small friction coefficient: it is conducive to reducing energy loss and heating.

4. Adapt to high-speed operation: it can still maintain good performance under high-speed conditions.

Classification

Classification

1. Single row cylindrical roller bearing: simple structure, can only withstand radial load.

2. Double row cylindrical roller bearings: can withstand larger radial load, carrying capacity is stronger.

3. Fully loaded cylindrical roller bearings: there is no cage, the number of rollers is large, and the carrying capacity is extremely high.

Basic Parameters

Basic Parameters

1. Inner diameter, outer diameter and width: determine the mounting size of the bearing.

2. Rated dynamic load and rated static load: characterizes the bearing capacity.

3. Limit speed: indicates the highest speed that the bearing can safely operate under certain conditions.

The Working Principle

The Working Principle

When cylindrical roller bearings are working, the cylindrical roller rolls between the inner and outer ring raceways, and reduces the movement resistance through rolling friction. When the bearing is stressed, the roller transfers the load to the raceway, so as to achieve the role of supporting and transferring the load.

Application Fields

Application Fields

1. Industrial machinery: such as machine tools, motors, fans, etc.

2. Automotive field: used in engine, transmission and other parts.

3. Heavy machinery: such as cranes, excavators, etc.

4. Aerospace: plays an important role in key parts such as aircraft engines.

- Previous: Self Aligning Roller Bearing

- Next: Thrust Ball Bearing

RELATED PRODUCTS