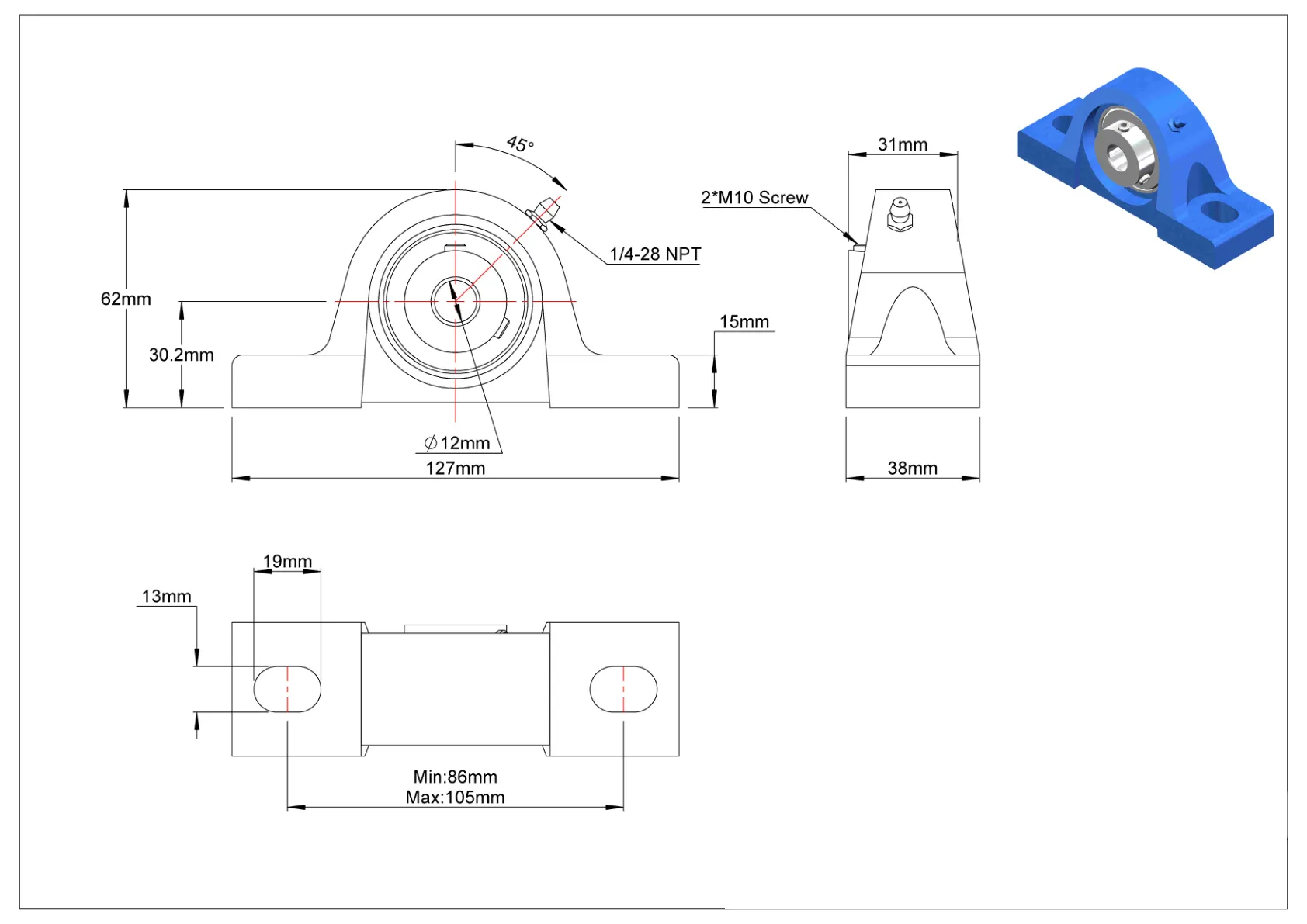

Basic Parameters

UCP201 is the model number of a spherical outside surface ball bearing with a vertical pedestal and set screws. The meaning is as follows:

UCP: Basic code, indicating the type of spherical outside surface ball bearing with a vertical pedestal and set screws.

2: Represents the series number of the bearing. Different series have certain regularities and differences in aspects such as size and load-carrying capacity. In the UCP series, the "2" series has its specific size and performance characteristics.

01: It is the code for the inner diameter size of the bearing, indicating the shaft diameter size that this bearing is adapted to. For UCP201, its adapted bearing inner diameter is 12mm

Performance feature

Performance feature

-

High strength and high load-bearing capacity: As a high-strength bolt, UCP201 has excellent strength performance. Its strength grade usually reaches 8.8 or 10.9, and it can bear a large load. It is suitable for steel structure projects with high connection strength requirements, such as industrial plants, bridges, high-rise buildings, etc., providing reliable guarantee for the stability and safety of the structure135.

-

Reliable connection performance: During the installation process of UCP201, by applying a large preload, it can make the connected steel structure components closely fit and generate a large friction force, thereby improving the integrity and stiffness of the connection. This friction-type connection method mainly relies on friction force to transfer external force when under stress, which can effectively avoid relative slip between components and ensure the reliability of the connection. It is especially suitable for structures that bear dynamic loads2.

-

Good fatigue resistance: After careful design and manufacturing, UCP201 has good fatigue resistance performance. It can maintain stable performance under repeated loads and is not prone to fatigue failure, prolonging the service life of steel structures and reducing maintenance and replacement costs.

Product Application

Building Steel Structure: Widely used in building steel structures such as industrial plants, warehouses, stadiums, and high-rise buildings. It is used to connect steel beams, steel columns, steel trusses and other components to ensure the overall stability and safety of the structure. For example, in industrial plants, UCP201 can be used to connect crane beams and columns and bear the dynamic load of 278 generated during crane operation.

Bridge Engineering: It is an important component for connecting bridge steel structures and can be used to connect main beams, piers, abutments and other parts of bridges. It can bear various loads on bridges during use, including vehicle loads, wind loads, seismic loads, etc., to ensure the structural safety and normal use of bridges.

Key points of construction

Key points of construction

-

Installation preparation: Before installing UCP201 high-strength bolts, it is necessary to ensure that the friction surfaces of the connecting components are clean, free of oil stains, floating rust and other impurities to ensure that the anti-slip coefficient of the friction surface meets the design requirements. At the same time, check the size and precision of the bolt holes to ensure that the bolts can be smoothly inserted.

-

Installation method: Professional installation tools such as torque wrenches or torsion shear electric wrenches should be used. During installation, perform initial tightening first to bring the laminates close together, and then perform final tightening to reach the specified preload. For torsion shear high-strength bolts, during final tightening, only the plum blossom chuck at the tail of the bolt needs to be twisted off. The operation is simple and convenient, and can effectively ensure the accuracy of the preload.

-

Construction precautions: During the construction process, operations must be carried out in strict accordance with relevant specifications and design requirements. It is forbidden to hammer in bolts to avoid damaging bolts and components. At the same time, pay attention to controlling the temperature and humidity of the construction environment and avoid splicing in a wet or rainy state to prevent the reduction of the anti-slip coefficient of the friction surface.

Product List

| Unit No. |

d |

H1 |

A |

E |

P |

S1 |

S2 |

H2 |

H |

B |

F |

bolt size |

| UCP201 |

12 |

30,2 |

127 |

95 |

38 |

13 |

19 |

14 |

62 |

31 |

12,7 |

M10 |

| UCP202 |

15 |

30,2 |

127 |

95 |

38 |

13 |

19 |

14 |

62 |

31 |

12,7 |

M10 |

| UCP203 |

17 |

30,2 |

127 |

95 |

38 |

13 |

19 |

14 |

62 |

31 |

12,7 |

M10 |

| UCP204 |

20 |

33,3 |

127 |

95 |

38 |

13 |

19 |

14 |

65 |

31 |

127,7 |

M10 |

| UCP205 |

25 |

36,5 |

140 |

105 |

38 |

13 |

19 |

15 |

71 |

34,1 |

14,3 |

M10 |

| UCPX05 |

25 |

44,4 |

159 |

119 |

51 |

17 |

20 |

18 |

85 |

38,1 |

15,9 |

M14 |

| UCP305 |

25 |

45 |

175 |

132 |

45 |

17 |

20 |

15 |

85 |

38 |

38 |

M14 |

| UCP206 |

30 |

42,9 |

165 |

121 |

48 |

17 |

20 |

17 |

84 |

38,1 |

15,9 |

M14 |

| UCPX06 |

30 |

47,6 |

175 |

127 |

57 |

17 |

20 |

20 |

93 |

42,9 |

17,5 |

M14 |

| UCP306 |

30 |

50 |

180 |

140 |

50 |

17 |

20 |

18 |

95 |

43 |

17 |

M14 |

| UCP207 |

35 |

47,6 |

167 |

127 |

48 |

17 |

20 |

18 |

93 |

42,9 |

17,5 |

M14 |

| UCPX07 |

35 |

54 |

203 |

144 |

57 |

17 |

20 |

21 |

105 |

49,2 |

19 |

M14 |

| UCP307 |

35 |

56 |

210 |

160 |

56 |

17 |

25 |

20 |

106 |

48 |

19 |

M14 |

| UCP208 |

40 |

49,2 |

184 |

137 |

54 |

17 |

20 |

18 |

100 |

49,2 |

19 |

M14 |

| UCPX08 |

40 |

58,7 |

222 |

156 |

67 |

20 |

23 |

26 |

111 |

49,2 |

19 |

M16 |

| UCP308 |

40 |

60 |

220 |

170 |

60 |

17 |

27 |

22 |

116 |

52 |

19 |

M14 |

| UCP209 |

45 |

54 |

190 |

146 |

54 |

17 |

20 |

20 |

106 |

49,2 |

19 |

M14 |

| UCPX09 |

45 |

58,7 |

222 |

156 |

67 |

20 |

23 |

26 |

116 |

51,6 |

19 |

M16 |

| UCP309 |

45 |

67 |

245 |

190 |

67 |

20 |

30 |

24 |

129 |

57 |

22 |

M16 |

| UCP210 |

50 |

57,2 |

206 |

159 |

60 |

20 |

23 |

21 |

113 |

51,6 |

19 |

M16 |

| UCPX10 |

50 |

63,5 |

241 |

171 |

73 |

20 |

23 |

27 |

126 |

55,6 |

22,2 |

M16 |

| UCP310 |

50 |

75 |

275 |

212 |

75 |

20 |

35 |

27 |

143 |

61 |

22 |

M16 |

| UCP211 |

55 |

63,5 |

219 |

171 |

60 |

20 |

23 |

23 |

125 |

55,6 |

22,2 |

M16 |

| UCPX11 |

55 |

69,8 |

260 |

184 |

79 |

25 |

28 |

30 |

137 |

65,1 |

25,4 |

M20 |

| UCP311 |

55 |

80 |

310 |

236 |

80 |

20 |

38 |

30 |

154 |

66 |

25 |

M16 |

| UCP212 |

60 |

69,8 |

241 |

184 |

70 |

20 |

23 |

25 |

138 |

65,1 |

25,4 |

M16 |

| UCPX12 |

60 |

76,2 |

286 |

203 |

83 |

25 |

28 |

33 |

151 |

65,1 |

25,4 |

M20 |

| UCP312 |

60 |

85 |

330 |

250 |

85 |

25 |

38 |

32 |

165 |

71 |

26 |

M20 |

| UCP213 |

65 |

76,2 |

265 |

203 |

70 |

25 |

28 |

27 |

150 |

65,1 |

25,4 |

M20 |

| UCPX13 |

65 |

76,2 |

286 |

203 |

83 |

25 |

28 |

33 |

154 |

74,6 |

30,2 |

M20 |

| UCP313 |

65 |

90 |

340 |

260 |

90 |

25 |

38 |

33 |

176 |

75 |

30 |

M20 |

| UCP214 |

70 |

79,4 |

266 |

210 |

72 |

25 |

28 |

27 |

156 |

74,6 |

30,2 |

M20 |

| UCPX14 |

70 |

88,9 |

330 |

229 |

89 |

27 |

30 |

35 |

170 |

77,8 |

33,3 |

M22 |

| UCP314 |

70 |

95 |

360 |

280 |

90 |

27 |

40 |

35 |

187 |

78 |

33 |

M22 |

| UCP215 |

75 |

82,6 |

275 |

217 |

74 |

25 |

28 |

28 |

162 |

77,8 |

33,3 |

M20 |

| UCPX15 |

75 |

88,9 |

330 |

229 |

89 |

27 |

30 |

35 |

175 |

82,6 |

33,3 |

M22 |

| UCP315 |

75 |

100 |

380 |

290 |

100 |

27 |

40 |

35 |

198 |

82 |

32 |

M22 |

| UCP216 |

80 |

88,9 |

292 |

232 |

78 |

25 |

28 |

30 |

174 |

82,6 |

33,3 |

M20 |

| UCPX16 |

80 |

101,6 |

381 |

283 |

102 |

27 |

30 |

40 |

194 |

85,7 |

34,1 |

M22 |

| UCP316 |

80 |

106 |

400 |

300 |

110 |

27 |

40 |

40 |

210 |

86 |

34 |

M22 |

| UCP217 |

85 |

95,2 |

310 |

247 |

83 |

25 |

28 |

32 |

185 |

85,7 |

34,1 |

M20 |

| UCPX17 |

85 |

101,6 |

381 |

283 |

102 |

27 |

30 |

40 |

200 |

96 |

39,7 |

M22 |

| UCP317 |

85 |

112 |

420 |

320 |

110 |

33 |

45 |

40 |

220 |

96 |

40 |

M27 |

| UCP218 |

90 |

101,6 |

327 |

262 |

88 |

27 |

30 |

33 |

198 |

96 |

39,7 |

M22 |

| UCP318 |

90 |

118 |

430 |

330 |

110 |

33 |

45 |

45 |

235 |

96 |

40 |

M27 |

| UCP319 |

95 |

125 |

470 |

360 |

120 |

36 |

50 |

45 |

250 |

103 |

41 |

M30 |

Basic Parameters

Basic Parameters Performance feature

Performance feature Product Application

Product Application Key points of construction

Key points of construction Product List

Product List