Basic Parameters

Type code:

"N" indicates cylindrical roller bearings. This is a key identification of the bearing type, clearly indicating that N210 belongs to the cylindrical roller bearing series. Cylindrical roller bearings are widely used in many industrial fields due to their ability to withstand large radial loads and are suitable for various equipment and mechanical systems that need to bear heavy radial loads.

Size series code:

"2" represents the size series. The size series code contains information on the width series and diameter series of the bearing. In cylindrical roller bearings, different size series correspond to different overall bearing size specifications. The "2" size series is usually suitable for application scenarios with medium size and load requirements. It determines the relative size of the N210 bearing in the entire cylindrical roller bearing series, helping users select bearings of appropriate sizes according to the specific design requirements of the equipment to ensure the best performance in a limited space.

Bore code:

"10" indicates the inner diameter size. According to the standard coding rule for bearing inner diameter codes, multiplying the inner diameter code by 5 gives the actual inner diameter size of the bearing. Therefore, "10" represents that the inner diameter of the N210 bearing is 50mm (10×5 = 50). The inner diameter size is a key parameter for the fit between the bearing and the shaft. An accurate inner diameter size can ensure a tight fit between the bearing and the shaft, enabling the bearing to effectively transmit loads during operation, reduce wear and heat generation, thereby extending the service life of the bearing and ensuring the stable operation of the equipment.

Structural Features

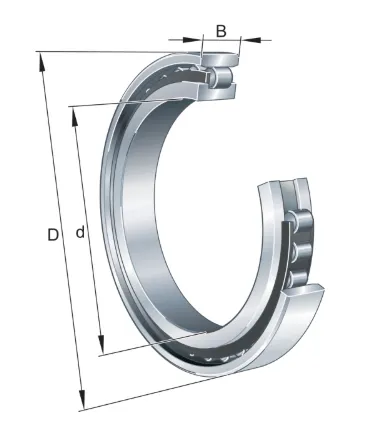

Double Flange Design on Inner and Outer Rings: The N210 bearing features a double flange structure on both the inner and outer rings. This design provides excellent stability and load-carrying capacity for the bearing. The double flanges on the inner and outer rings effectively limit the axial displacement of the rollers, ensuring that the rollers always remain in the correct position during operation and achieving precise and stable rotational movement. This structure enables the bearing to withstand large radial loads and also adapt to a certain degree of axial load, providing a solid guarantee for the stable operation of equipment under complex working conditions.

Optimized Design of Cage: The N210 bearing is equipped with a carefully designed cage, which plays a crucial role. The cage can evenly separate the rollers, avoiding collisions between rollers and thereby reducing friction and wear and extending the service life of the bearing. At the same time, the optimized cage structure helps maintain the correct movement trajectory of the rollers, further improving the operating accuracy and stability of the bearing. During high-speed rotation, the cage can effectively control the movement of the rollers, reducing vibration and noise and ensuring the smooth operation of the equipment.

Convenience of Separable Structure: The N210 bearing has a separable structure, which brings great convenience to the installation and disassembly processes. You can easily separate or assemble the inner ring, outer ring, rollers, and cage without the need for complex tools or professional equipment. This characteristic is particularly prominent in equipment maintenance and repair work. When it is necessary to replace the bearing or conduct equipment inspection and repair, the separable structure can greatly shorten the downtime, reduce the impact on production, and save you time and cost.

Performance Advantage

-

High load-carrying capacity performance: Thanks to its optimized structural design, the N210 bearing shows excellent performance in load-carrying capacity. Whether it is radial load or a certain axial load, it can easily handle it. In industrial equipment such as various transmission devices and heavy machinery, they often face huge load challenges. With its strong load-carrying capacity, the N210 bearing can stably bear these loads, ensure the normal operation of the equipment, effectively extend the service life of the equipment, and reduce maintenance costs and downtime caused by bearing failures.

-

Good high-speed adaptability: In application scenarios with high-speed operation, the N210 bearing also shows excellent performance. Its special roller design and precise manufacturing process enable the bearing to maintain a low friction coefficient and stable working temperature when rotating at high speed. This means that in high-speed equipment such as motors and machine tool spindles, the N210 bearing can effectively reduce energy loss, improve the operating efficiency of the equipment, and ensure the smoothness and reliability of operation. Even under long-term high-speed operation, it can maintain stable performance and provide continuous power support for your production process.

-

High precision and stability guarantee: For equipment with high precision requirements, such as precision instruments and CNC machine tools, the N210 bearing is an ideal choice. Its excellent rotational precision and stability can ensure accurate positioning and motion control during the operation of the equipment. In the precision machining process, the N210 bearing can effectively reduce vibration and deviation, improve machining precision and product quality, and provide reliable performance guarantee for your high-end equipment and enhance the market competitiveness of products.

Product Application

-

Application in industrial transmission field: In various industrial transmission equipment, the N210 bearing plays a key role. For example, in reducers, transmissions, conveyor belts and other equipment, it can stably transmit power and ensure the smooth operation of the equipment. Its good load-bearing capacity and high-speed performance enable industrial transmission equipment to efficiently complete various production tasks. Whether in low-speed heavy-load or high-speed operating conditions, the N210 bearing can provide stable support for the transmission system and ensure the continuity of industrial production.

-

Application in machine tool equipment: As a precision machining equipment, machine tools have extremely high requirements for bearings. The N210 bearing is widely used in key parts such as machine tool spindles and worktables. It can meet the needs of machine tools in high-speed cutting and high-precision machining processes and ensure the rotational accuracy and positioning accuracy of machine tools. During the machining process, the stable performance of the N210 bearing helps reduce tool wear and improve the machining surface quality, thereby enhancing the overall machining performance of the machine tool and providing a reliable guarantee for manufacturing high-precision mechanical parts and helping the development of the manufacturing industry.

-

Application scenarios in the automotive industry: In parts such as the engine, transmission, and wheel hub of a car, the N210 bearing also has a wide range of applications. It can adapt to the complex load changes of cars under different road conditions and driving conditions and ensure the reliability and durability of vehicles. In the engine, it provides stable support for the rotation of the crankshaft; in the transmission, it ensures the smooth meshing of gears; in the wheel hub part, it bears various loads when the vehicle is driving, providing a solid guarantee for your travel safety and improving the overall performance and driving experience of the car.

-

-

industrial transmission

-

machine tool equipment

-

automotive industry

Product Type

| Bearing No. |

Dimensions (mm) |

Basic Load Rating (N) |

Weight |

| ISO |

GOST |

d |

D |

B |

Dyn. C |

Stat. C0 |

(kg) |

| N202 |

2202 |

15 |

35 |

11 |

13500 |

11600 |

0.047 |

| N203 |

2203 |

17 |

40 |

12 |

14800 |

12100 |

0.067 |

| N204 |

2204 |

20 |

47 |

14 |

15400 |

12700 |

0.108 |

| N205 |

2205 |

25 |

52 |

15 |

17700 |

15700 |

0.132 |

| N206 |

2206 |

30 |

62 |

16 |

23500 |

21500 |

0.2 |

| N207 |

2207 |

35 |

72 |

17 |

33600 |

31500 |

0.293 |

| N208 |

2208 |

40 |

80 |

18 |

43800 |

42900 |

0.366 |

| N209 |

2209 |

45 |

85 |

19 |

46100 |

46900 |

0.427 |

| N210 |

2210 |

50 |

90 |

20 |

48200 |

51000 |

0.479 |

| N211 |

2211 |

55 |

100 |

21 |

58000 |

62300 |

0.64 |

| N212 |

2212 |

60 |

110 |

22 |

71900 |

79900 |

0.823 |

| N213 |

2213 |

65 |

120 |

23 |

83800 |

94400 |

1.05 |

| N214 |

2214 |

70 |

125 |

24 |

83300 |

95200 |

1.15 |

| N215 |

2215 |

75 |

130 |

25 |

101000 |

118000 |

1.24 |

| N216 |

2216 |

80 |

140 |

26 |

106000 |

122000 |

1.51 |

| N217 |

2217 |

85 |

150 |

28 |

121000 |

140000 |

1.9 |

| N218 |

2218 |

90 |

160 |

30 |

152000 |

178000 |

2.28 |

| N219 |

2219 |

95 |

170 |

32 |

165000 |

195000 |

2.8 |

| N220 |

2220 |

100 |

180 |

34 |

183000 |

217000 |

3.38 |

| N224 |

2224 |

120 |

215 |

40 |

260000 |

318000 |

5.65 |

| N226 |

2226 |

130 |

230 |

40 |

282000 |

362000 |

6.49 |

| N228 |

2228 |

140 |

250 |

42 |

324000 |

421000 |

8.27 |

| N230 |

2230 |

150 |

270 |

45 |

374000 |

492000 |

10.3 |

| N232 |

2232 |

160 |

290 |

48 |

427000 |

568000 |

14.4 |

| N234 |

2234 |

170 |

310 |

52 |

475000 |

637000 |

18.4 |

| N236 |

2236 |

180 |

320 |

52 |

492000 |

677000 |

19.3 |

Basic Parameters

Basic Parameters

Structural Features

Structural Features Product Application

Product Application Product Type

Product Type