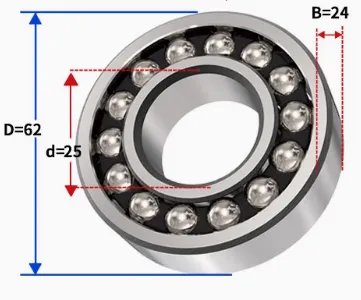

Self aligning ball bearing:2305

Basic Parameters

Basic ParametersIn bearing 2305, The meanings of the numbers in the bearing 2305 are as follows: -The first digit "2" It indicates that the type of the bearing is a self-aligning ball bearing. According to the classification rules of bearing models, different numbers represent different types of bearings. For example, "0" represents deep groove ball bearings, "1" represents self-aligning ball bearings, "2" represents cylindrical roller bearings, etc. Here, the "2" clearly identifies that this bearing is of the self-aligning ball bearing type. - The last three digits "305": Among them, "05" represents the inner diameter size of the bearing. Generally, when the inner diameter of the bearing is within the range of 20mm to 480mm, the inner diameter size is obtained by multiplying the last two digits by 5. So, multiplying "05" by 5 gives that the inner diameter of this bearing is 25mm. And the third digit "3" is the diameter series code, which is used to represent different combinations of outer diameter and width dimensions for the same inner diameter size. The larger the number, the relatively larger the outer diameter and width will be, and the stronger the bearing capacity will be.

图片文字描述1

performance characteristics

performance characteristics Material and Manufacturing Process

Material and Manufacturing Process

Inner and Outer Ring Materials

For the 2305 bearing, the inner and outer rings are usually made of high-quality bearing steel, such as GCr15 (high-carbon chromium bearing steel). This kind of steel has high hardness, high strength and good wear resistance. Through precise forging and processing technology, the dimensional accuracy of the inner and outer rings can be controlled within a very small tolerance range, ensuring the rotational accuracy of the bearing. For example, the roundness error of the inner and outer rings can be controlled at the micron level, so that the rolling elements can roll smoothly between the inner and outer rings.

Rolling Element Materials

Rolling elements are generally also made of high-quality bearing steel. And during the manufacturing process, it will go through strict heat treatment processes such as quenching and tempering to improve the hardness and toughness of the rolling elements. Such rolling elements can effectively resist deformation and fatigue damage when bearing loads and rotating at high speeds.

Cage Material and Structure

Common materials for cages are stamped steel plates or engineering plastics. Stamped steel cage has high strength and stability, and can well separate the rolling elements evenly and prevent mutual collisions between the rolling elements. The engineering plastic cage has the advantages of self-lubrication and light weight, which can reduce the centrifugal force of the bearing during high-speed rotation and reduce energy loss. Its structural design is reasonable, which can ensure that the rolling elements roll on the correct track and facilitate the storage and circulation of lubricants.

Lubrication and Maintenance Suggestions

Lubrication and Maintenance Suggestions

Product Application

Product Application

Product List

Product List

| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight | ||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | (kg) |

| 2300 | 1600 | 10 | 35 | 17 | 10000 | 2100 | 0.08 |

| 2301 | 1601 | 12 | 37 | 17 | 11400 | 2600 | 0.091 |

| 2302 | 1602 | 15 | 42 | 17 | 11800 | 2800 | 0.108 |

| 2303 | 1603 | 17 | 47 | 19 | 14300 | 3500 | 0.168 |

| 2304 | 1604 | 20 | 52 | 21 | 17800 | 4750 | 0.21 |

| 2305 | 1605 | 25 | 62 | 24 | 24500 | 6480 | 0.335 |

| 2306 | 1606 | 30 | 72 | 27 | 31500 | 8680 | 0.5 |

| 2307 | 1607 | 35 | 80 | 31 | 39200 | 11000 | 0.675 |

| 2308 | 1608 | 40 | 90 | 33 | 44800 | 13200 | 0.925 |

| 2309 | 1609 | 45 | 100 | 36 | 55000 | 16200 | 1.23 |

| 2310 | 1610 | 50 | 110 | 40 | 64500 | 19800 | 1.63 |

| 2311 | 1611 | 55 | 120 | 43 | 75200 | 23500 | 2.09 |

| 2312 | 1612 | 60 | 130 | 46 | 86800 | 27500 | 2.6 |

| 2313 | 1613 | 65 | 140 | 48 | 96000 | 32500 | 3.2 |

| 2314 | 1614 | 70 | 150 | 51 | 110000 | 37500 | 3.92 |

| 2315 | 1615 | 75 | 160 | 55 | 122000 | 42800 | 4.78 |

| 2316 | 1616 | 80 | 170 | 58 | 128000 | 45500 | 5.65 |

| 1205 K | 111205 | 25 | 52 | 15 | 12000 | 3300 | 0.14 |

| 1206 K | 111206 | 30 | 62 | 16 | 15800 | 4700 | 0.22 |

| 1207 K | 111207 | 35 | 72 | 17 | 15800 | 5080 | 0.32 |

| 1208 K | 111208 | 40 | 80 | 18 | 19200 | 6400 | 0.415 |

| 1209 K | 111209 | 45 | 85 | 19 | 21800 | 7320 | 0.465 |

| 1210 K | 111210 | 50 | 90 | 20 | 22800 | 8080 | 0.531 |

| 1211 K | 111211 | 55 | 100 | 21 | 26800 | 10000 | 0.705 |

| 1212 K | 111212 | 60 | 110 | 22 | 30200 | 11500 | 0.9 |

| 1213 K | 111213 | 65 | 120 | 23 | 31000 | 12500 | 1.15 |

| 1215 K | 111215 | 75 | 130 | 25 | 38800 | 15200 | 1.39 |

| 1216 K | 111216 | 80 | 140 | 26 | 39500 | 16800 | 1.7 |

| 1217 K | 111217 | 85 | 150 | 28 | 48800 | 20500 | 2.06 |

| 1218 K | 111218 | 90 | 160 | 30 | 56500 | 23200 | 2.59 |

| 1220 K | 111220 | 100 | 180 | 34 | 67400 | 28400 | 3.7 |

| 1306 K | 111306 | 30 | 72 | 19 | 21500 | 6280 | 0.385 |

| 1307 K | 111307 | 35 | 80 | 21 | 25000 | 7950 | 0.51 |

| 1308 K | 111308 | 40 | 90 | 23 | 29500 | 9500 | 0.715 |

| 1309 K | 111309 | 45 | 100 | 25 | 38000 | 12800 | 0.955 |

| 1310 K | 111310 | 50 | 110 | 27 | 43200 | 14200 | 1.2 |

| 1311 K | 111311 | 55 | 120 | 29 | 51500 | 18200 | 1.6 |

| 1312 K | 111312 | 60 | 130 | 31 | 57200 | 21200 | 1.95 |

| 1313 K | 111313 | 65 | 140 | 33 | 61800 | 22800 | 2.42 |

| 1315 K | 111315 | 75 | 160 | 37 | 79000 | 29800 | 3.55 |

| 1316 K | 111316 | 80 | 170 | 39 | 86700 | 31400 | 4.17 |

| 1318 K | 111318 | 90 | 190 | 43 | 115000 | 42000 | 5.8 |

| 1320 K | 111320 | 100 | 215 | 47 | 141000 | 55000 | 8.3 |

| 1322 K | 111322 | 110 | 240 | 50 | 161000 | 70000 | 12 |

- Previous: Taper roller bearing:30306

- Next: Self aligning ball bearing:1308

RELATED PRODUCTS