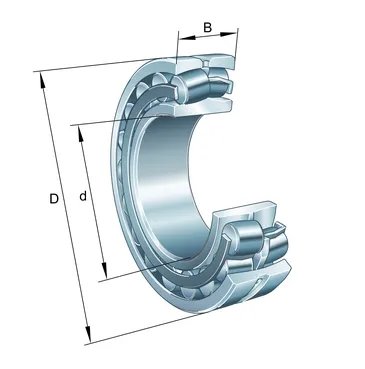

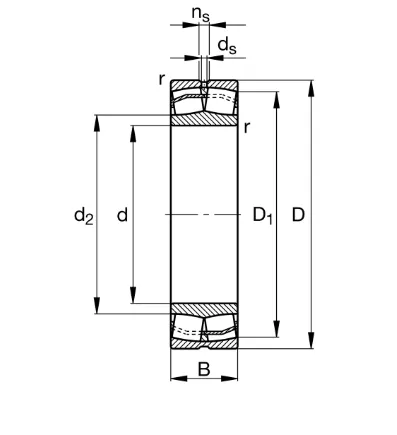

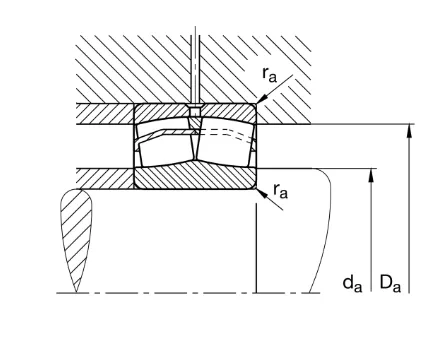

Basic Parameters

-

Inner diameter size: 60mm. This size determines that it is suitable for shafts with an inner diameter of 60mm and can fit tightly with the shaft to ensure the stability of the equipment during operation.

-

Outer diameter size: 130mm. The size of the outer diameter plays an important role in the installation space of the bearing in the equipment and its adaptability to surrounding components. The outer diameter of 130mm enables it to function in a suitable equipment structure.

-

Width size: 46mm. This width parameter ensures sufficient support area for the bearing and helps to bear loads in various directions."

-

22312KCW33

-

22312KCW33

-

22312KCW33

Type characteristics

Type characteristics

-

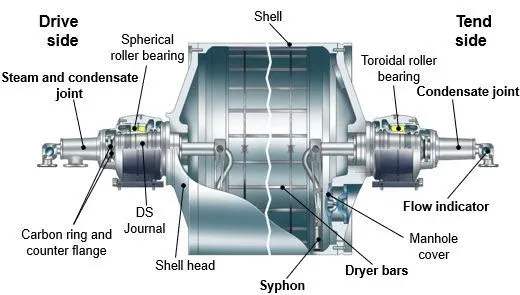

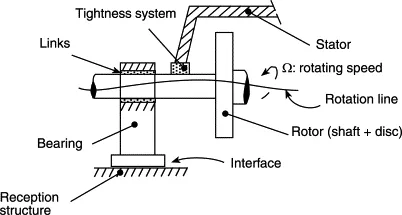

Bearing 22312KCW33 belongs to spherical roller bearings. The biggest characteristic of spherical roller bearings is that they have an automatic self-aligning function. During the operation of the equipment, if there is a certain angular deviation between the shaft and the housing hole due to installation errors, shaft deflection or other factors, this kind of bearing can automatically adapt to this angular change and effectively avoid stress concentration and premature wear caused by misalignment between the shaft and the housing hole. This characteristic makes it exhibit excellent performance in equipment where shaft deformation may occur or installation accuracy is difficult to ensure.

-

It can bear large radial loads and axial loads at the same time. Whether it is bearing the weight and centrifugal force from the operating parts of the equipment in the radial direction or dealing with the axial force generated by power transmission, vibration, etc. in the axial direction, bearing 22312KCW33 can play a role stably and reliably. For example, in some large conveyor belt rollers, drying cylinders of paper machines, and rotating parts of construction machinery, this ability to bear radial and axial loads simultaneously can ensure the long-term stable operation of the equipment.

Performance advantages

Performance advantages

-

High load-carrying capacity: Due to its internal structure design and the distribution of rollers, the 22312KCW33 bearing can bear heavy loads. This enables it to be applied in heavy-duty equipment such as heavy mining machinery and large cranes, providing solid support for the key components of the equipment and ensuring that the equipment can still operate normally under high-load conditions.

-

Good wear resistance: In the manufacturing process of the bearing, high-quality materials and advanced processing technologies are adopted. The contact surface between the roller and the raceway is finely ground, and both hardness and surface finish reach a very high standard. This high-quality surface treatment and material performance enable the bearing to effectively resist wear during long-term operation, reducing problems such as increased clearance and decreased precision caused by wear, thereby prolonging the service life of the bearing.

-

Stable operating performance: The self-aligning roller bearing 22312KCW33 can maintain a low level of vibration and noise during high-speed operation. This is due to its precise manufacturing process and optimized internal structure. Stable operating performance can not only improve the working efficiency of the equipment but also provide operators with a relatively quiet and comfortable working environment. At the same time, it also helps to reduce damage to other components of the equipment caused by vibration.‘

-

-

Applicable scene

Applicable scene

-

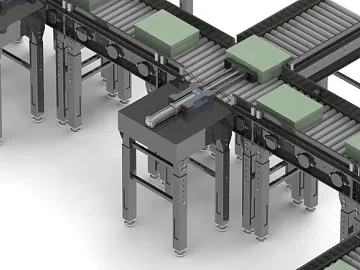

Industrial field: Widely used in various industrial equipment such as motors, reducers, fans, etc. Taking motors as an example, during the high-speed rotation of the motor rotor, the bearing needs to bear the weight of the rotor and the centrifugal force generated by rotation. The high load-carrying capacity and stability of the 22312KCW33 bearing can ensure the long-term stable operation of the motor and reduce the failure rate.

-

Construction machinery field: Also frequently used in the slewing mechanism and traveling mechanism of construction machinery such as excavators and loaders. These equipment will be subjected to huge impact forces and variable loads during the working process. The self-aligning performance and high load-carrying capacity of the 22312KCW33 bearing can well adapt to this complex working condition and ensure the reliability and durability of construction machinery

-

Maintenance Suggestions

Maintenance SuggestionsFor ensuring the performance and service life of bearing 22312KCW33, regular maintenance is extremely important. Firstly, it is necessary to ensure good lubrication of the bearing. According to the operating environment and working conditions of the equipment, select the appropriate lubricant and lubrication method. Generally speaking, grease is a commonly used lubricant. It can form a protective film between the rollers and raceways to reduce friction and wear.

Secondly, pay attention to keeping the bearing clean. During the operation of the equipment, prevent dust, impurities, etc. from entering the interior of the bearing. If there is a lot of dust or impurities around the bearing, it should be cleaned up in time to avoid them entering the interior of the bearing and causing wear on the rollers and raceways.

In addition, regular inspection of the operating state of the bearing is also essential. Through observing parameters such as the temperature, vibration, and noise of the bearing, potential problems can be discovered in time. If abnormal temperature rise, increased vibration, or increased noise of the bearing is found, it may indicate that there are problems such as bearing failure or poor lubrication. It is necessary to stop the machine for inspection in time and conduct repair or replacement.

Product List

| Bearing No. |

Dimensions (mm) |

Basic Load Rating (N) |

Weight |

| ISO |

GOST |

d |

D |

B |

Dyn. C |

Stat. C0 |

(kg) |

| 22205 KCW33 |

153505 H |

25 |

52 |

18 |

35800 |

36800 |

0.169 |

| 22206 KCW33 |

153506 H |

30 |

62 |

20 |

50500 |

55000 |

0.26 |

| 22207 KCW33 |

153507 H |

35 |

72 |

23 |

66500 |

76000 |

0.397 |

| 22208 KCW33 |

153508 H |

40 |

80 |

23 |

78500 |

90800 |

0.493 |

| 22209 KCW33 |

153509 H |

45 |

85 |

23 |

82000 |

97500 |

0.551 |

| 22210 KCW33 |

153510 H |

50 |

90 |

23 |

84500 |

105000 |

0.61 |

| 22211 KCW33 |

153511 H |

55 |

100 |

25 |

102000 |

125000 |

0.82 |

| 22212 KCW33 |

153512 H |

60 |

110 |

28 |

122000 |

155000 |

1.088 |

| 22213 KCW33 |

153513 H |

65 |

120 |

31 |

150000 |

195000 |

1.5 |

| 22214 KCW33 |

153514 H |

70 |

125 |

31 |

158000 |

205000 |

1.552 |

| 22215 KCW33 |

153515 H |

75 |

130 |

31 |

162000 |

215000 |

1.58 |

| 22216 KCW33 |

153516 H |

80 |

140 |

33 |

175000 |

238000 |

2 |

| 22217 KCW33 |

153517 H |

85 |

150 |

36 |

210000 |

278000 |

2.451 |

| 22218 KCW33 |

153518 H |

90 |

160 |

40 |

240000 |

322000 |

3.236 |

| 22219 KCW33 |

153519 H |

95 |

170 |

43 |

278000 |

380000 |

3.89 |

| 22220 KCW33 |

153520 H |

100 |

180 |

46 |

310000 |

425000 |

4.746 |

| 22222 KCW33 |

153522 H |

110 |

200 |

53 |

405000 |

575000 |

6.994 |

| 22224 KCW33 |

153524 H |

120 |

215 |

58 |

470000 |

678000 |

8.63 |

| 22308 KCW33 |

153608 H |

40 |

90 |

33 |

120000 |

138000 |

0.978 |

| 22309 KCW33 |

153609 H |

45 |

100 |

36 |

142000 |

170000 |

1.332 |

| 22310 KCW33 |

153610 H |

50 |

110 |

40 |

175000 |

210000 |

1.76 |

| 22311 KCW33 |

153611 H |

55 |

120 |

43 |

208000 |

250000 |

2.234 |

| 22312 KCW33 |

153612 H |

60 |

130 |

46 |

238000 |

285000 |

2.721 |

| 22313 KCW33 |

153613 H |

65 |

140 |

48 |

260000 |

315000 |

3.412 |

| 22314 KCW33 |

153614 H |

70 |

150 |

51 |

292000 |

362000 |

4.19 |

| 22315 KCW33 |

153615 H |

75 |

160 |

55 |

342000 |

438000 |

5.031 |

| 22316 KCW33 |

153616 H |

80 |

170 |

58 |

385000 |

498000 |

6.012 |

| 22317 KCW33 |

153617 H |

85 |

180 |

60 |

420000 |

540000 |

6.776 |

| 22318 KCW33 |

153618 H |

90 |

190 |

64 |

475000 |

622000 |

8.201 |

| 22319 KCW33 |

153619 H |

95 |

200 |

67 |

520000 |

688000 |

9.21 |

| 22320 KCW33 |

153620 H |

100 |

215 |

73 |

608000 |

815000 |

11.87 |

Basic Parameters

Basic Parameters Type characteristics

Type characteristics Performance advantages

Performance advantages

Maintenance Suggestions

Maintenance Suggestions Product List

Product List