Taper roller bearing:30206

Basic Parameters

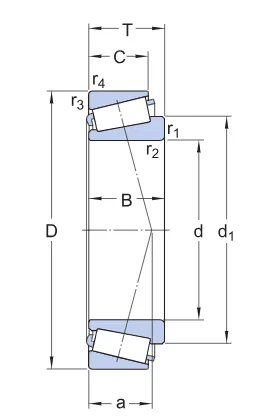

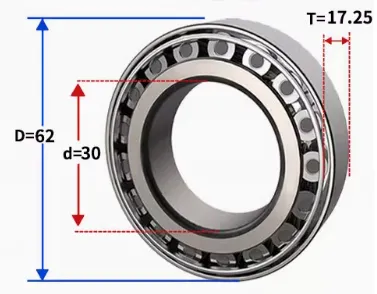

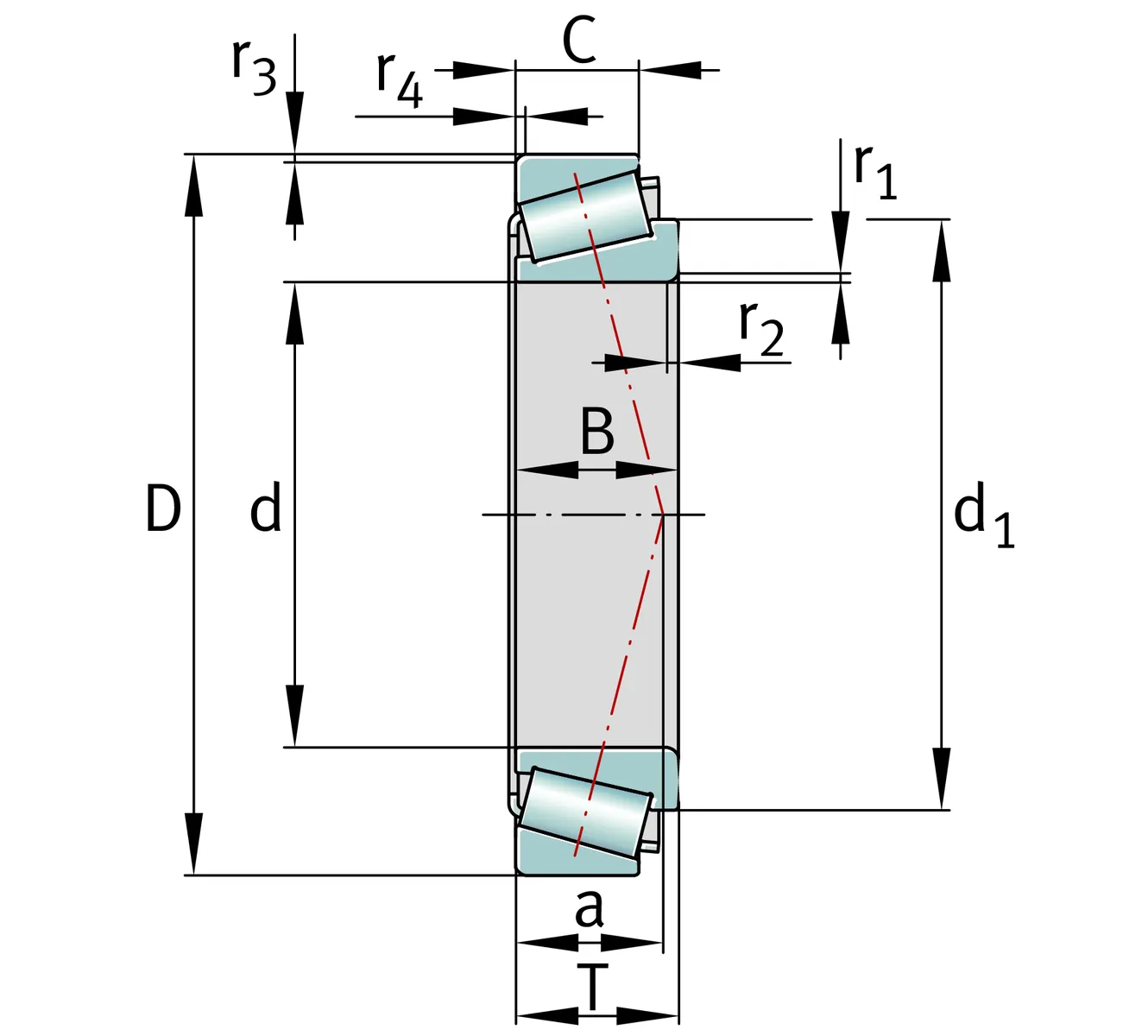

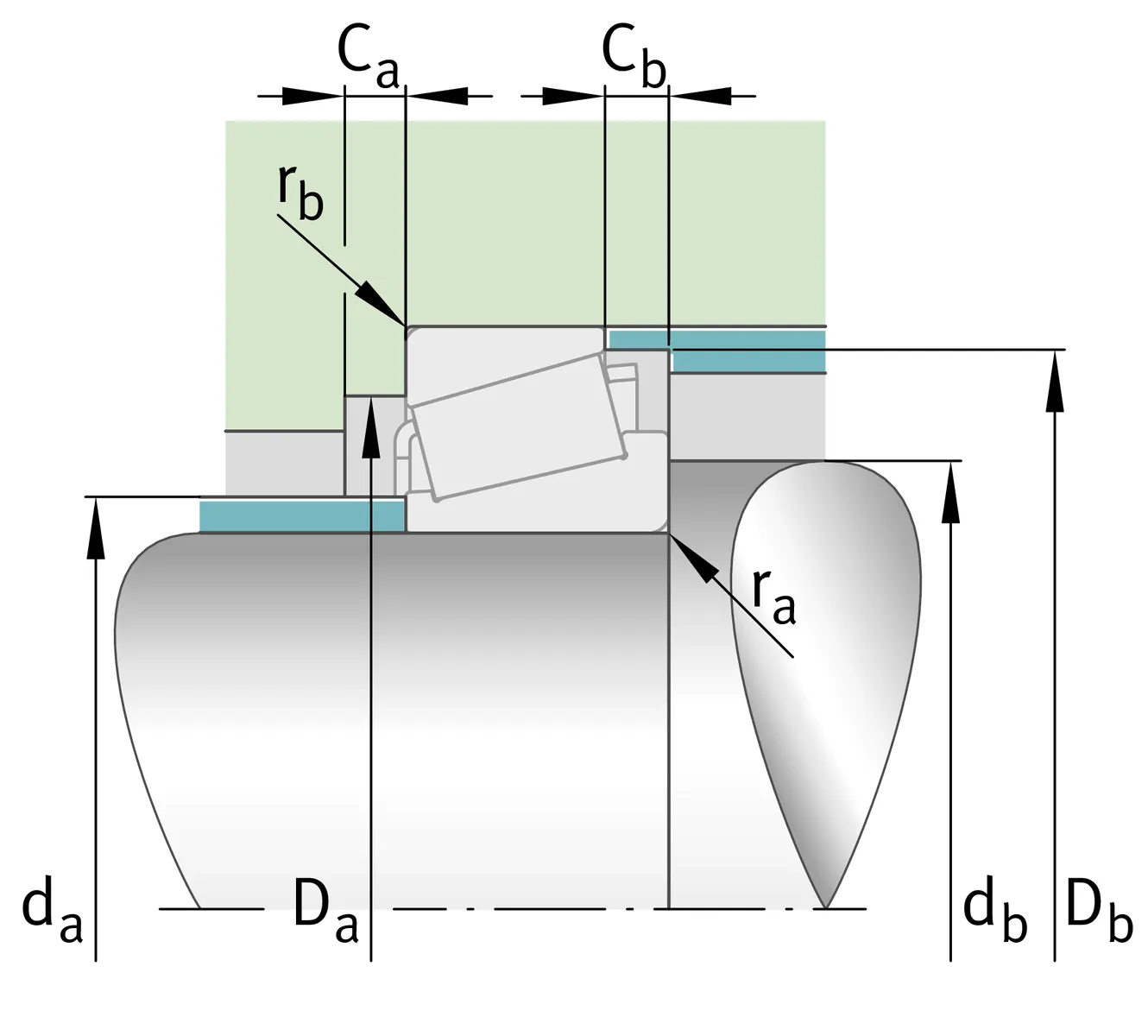

Basic ParametersIn bearing30206,The first two digits "30" represent the outer diameter size series of the bearing, the third digit "2" indicates the width series of the bearing, and the last two digits "06" denote the inner diameter size. Therefore, the inner diameter of the 30206 bearing is 30 millimeters, while the outer diameter and width dimensions are determined according to the standard series.

-

30206

-

30206

-

30206

Application Characteristics

Application Characteristics- Load - bearing Capacity:It can bear the combined load mainly consisting of radial load with a certain axial component. The load - bearing capacity is affected by the angle of the outer ring raceway. The larger the angle, the stronger the load - bearing capacity.

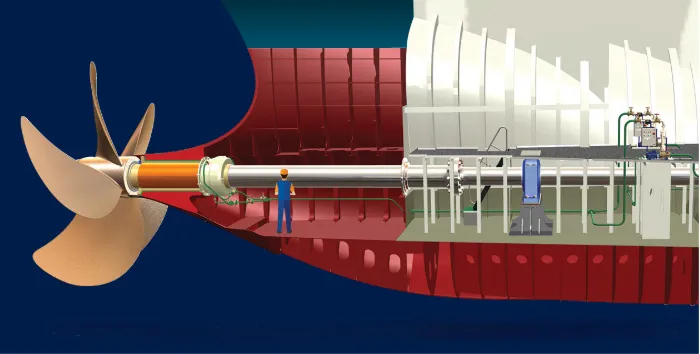

- Suitable Scenarios:It is applicable to automobiles, ships, agricultural machinery, machine tools, etc., and can be used in various mechanical devices that bear combined loads.

-

automobiles

-

ships

-

agricultural

Installation Methods

Installation Methods- Pre-installation Preparation: The installation should be carried out in a dry and clean environment. Carefully check the machining quality of the mating surfaces of the shaft and housing, remove burrs, molding sand, etc., and clean the bearings with gasoline or kerosene. Use them after drying, and ensure good lubrication at the same time. When using grease lubrication, select high-performance grease, and the filling amount should be 30% - 60% of the volume of the bearing and the bearing housing.

- Selection of Installation Methods: Depending on the magnitude of the interference fit. If the interference fit is small, the bearing can be installed at room temperature by using a sleeve combined with a hammer. For mass installation, a hydraulic press can be used. When the interference fit is large, methods such as oil bath heating or induction heating can be adopted for installation. The heating temperature range is 80 °C - 100 °C, and the maximum should not exceed 120 °C. After installation, it is necessary to fasten it with nuts, etc. to prevent gaps caused by cooling and contraction.

- Key Points of Installation Operation: During installation, equal pressure should be applied on the circumference of the end face of the ring to press the ring in. It is strictly prohibited to directly strike the end face of the bearing with a hammer. For single-row tapered roller bearings, the clearance needs to be adjusted after installation. For double-row tapered roller bearings and pump shaft bearings, the clearance has been adjusted before leaving the factory and does not need to be adjusted. - - Post-installation Inspection: After the bearing is installed, a rotation test should be carried out. First, manually rotate the shaft or the bearing housing. If there is no abnormality, then drive it with power for no-load and low-speed operation. Subsequently, gradually increase the rotational speed and load, and detect noise, vibration and temperature rise. Only when everything is normal can it be delivered for use.

Maintenance Methods

Maintenance Methods- Regular Inspection: Regularly check the operating status of the bearings, including whether the rotation sound, vibration, temperature, etc. are normal. Check the wear conditions of components such as the raceway surface, rolling elements, cages, and whether the bearing clearance has increased.

- Lubrication Management: According to the working conditions and requirements, regularly replenish or replace grease or lubricating oil to ensure good lubrication of the bearings and extend their service life.

- Cleaning and Maintenance: When impurities such as sand are found in the bearings, the lubricating oil deteriorates, or after a certain period of operation, it is necessary to clean the bearings in a timely manner. First, remove the old oil, and then use a brush or cloth dipped in gasoline or kerosene to clean it at least twice. After cleaning, dry it. Do not use cotton yarn to wipe it to prevent fluff from falling into the bearings.

- Fault Handling: If faults occur in the bearings, such as deformation of the cage and wear of the rollers, it is necessary to replace the faulty components in a timely manner. If the bearings are seriously damaged, they should be replaced as a whole. At the same time, analyze the causes of the faults and take corresponding measures to prevent similar problems from occurring again.

Product List

Product List| Bearing No. | Dimensions (mm) | Basic Load Rating(N) | weight | ||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | kg |

| 30202 | 7202 | 15 | 35 | 11 | 12500 | 11800 | 0.057 |

| 30203 | 7203 | 17 | 40 | 12 | 19000 | 18600 | 0.075 |

| 30204 | 7204 | 20 | 47 | 14 | 27500 | 28000 | 0.120 |

| 30205 | 7205 | 25 | 52 | 15 | 30800 | 33500 | 0.150 |

| 30206 | 7206 | 30 | 62 | 16 | 40200 | 44000 | 0.230 |

| 30207 | 7207 | 35 | 72 | 17 | 51200 | 56000 | 0.320 |

| 30208 | 7208 | 40 | 80 | 18 | 61600 | 68000 | 0.420 |

| 30209 | 7209 | 45 | 85 | 19 | 66000 | 76500 | 0.480 |

| 30210 | 7210 | 50 | 90 | 20 | 76500 | 91500 | 0.540 |

| 30211 | 7211 | 55 | 100 | 21 | 89700 | 106000 | 0.700 |

| 30212 | 7212 | 60 | 110 | 22 | 99000 | 114000 | 0.880 |

| 30213 | 7213 | 65 | 120 | 23 | 114000 | 134000 | 1.150 |

| 30214 | 7214 | 70 | 125 | 24 | 125000 | 156000 | 1.250 |

| 30215 | 7215 | 75 | 130 | 25 | 140000 | 176000 | 1.400 |

| 30216 | 7216 | 80 | 140 | 26 | 151000 | 183000 | 1.600 |

| 30217 | 7217 | 85 | 150 | 28 | 176000 | 220000 | 2.050 |

| 30218 | 7218 | 90 | 160 | 30 | 194000 | 245000 | 2.550 |

| 30219 | 7219 | 95 | 170 | 32 | 216000 | 275000 | 3.000 |

| 30220 | 7220 | 100 | 180 | 34 | 246000 | 320000 | 3.650 |

| 30221 | 7221 | 105 | 190 | 36 | 270000 | 355000 | 4.250 |

| 30222 | 7222 | 110 | 200 | 38 | 308000 | 405000 | 5.100 |

| 30224 | 7224 | 120 | 215 | 40 | 341000 | 465000 | 6.150 |

| 30226 | 7226 | 130 | 230 | 40 | 369000 | 490000 | 7.600 |

| 30228 | 7228 | 140 | 250 | 42 | 418000 | 570000 | 8.650 |

| 30230 | 7230 | 150 | 270 | 45 | 429000 | 590000 | 11.000 |

| 30232 | 7232 | 160 | 290 | 48 | 528000 | 735000 | 13.000 |

| 30234 | 7234 | 170 | 310 | 52 | 590000 | 810000 | 19.000 |

| 30236 | 7236 | 180 | 320 | 52 | 610000 | 850000 | 20.000 |

| 30238 | 7238 | 190 | 340 | 55 | 721000 | 1000000 | 24.000 |

| 30240 | 7240 | 200 | 360 | 58 | 792000 | 1120000 | 25.000 |

- Previous: Custom Non-Standard Bearings

- Next: Deep groove ball bearing:6005

RELATED PRODUCTS