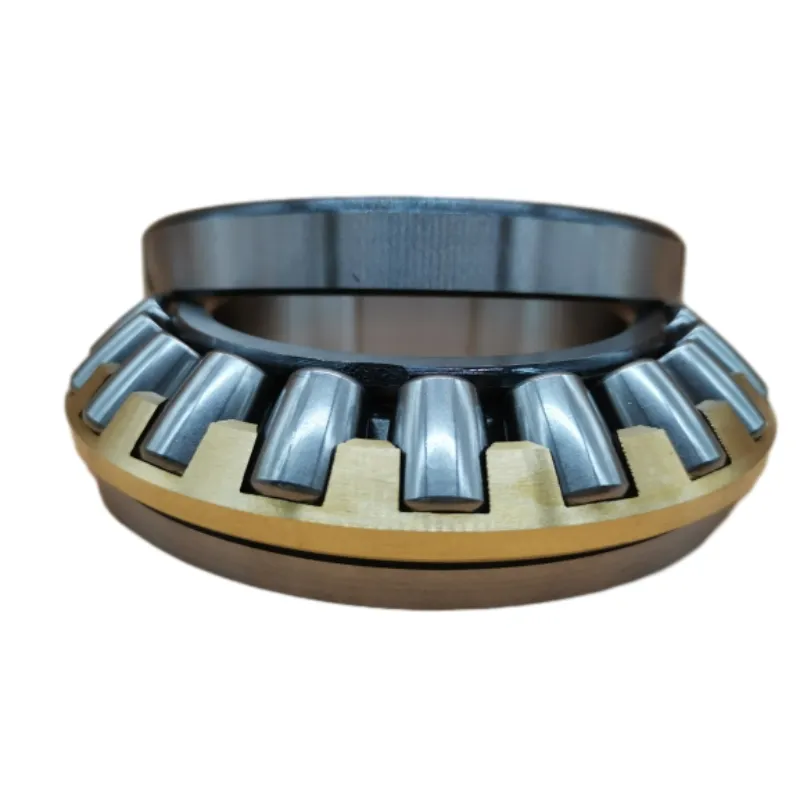

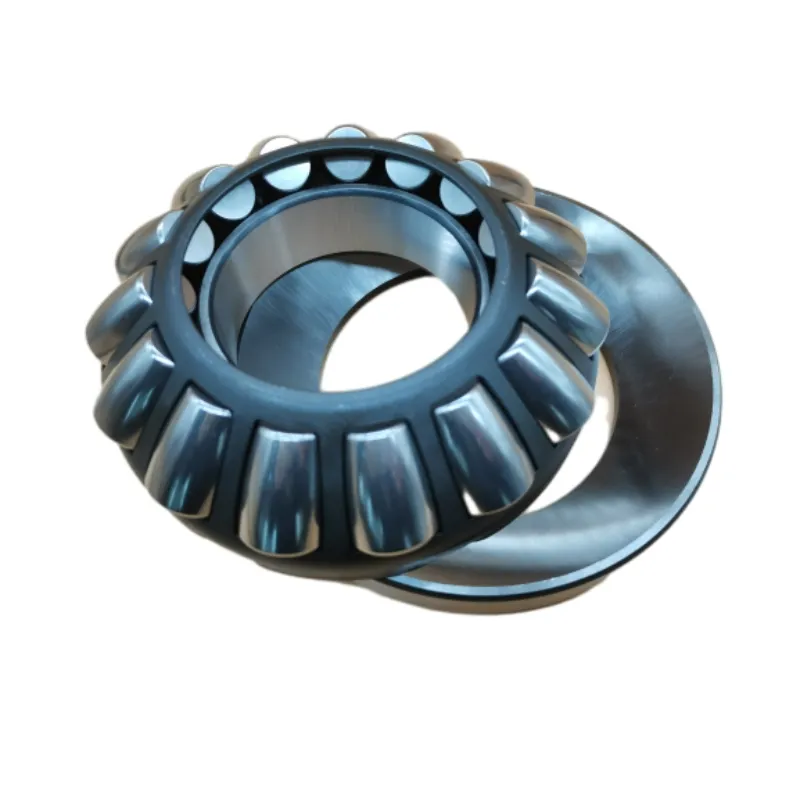

Thrust Roller Bearing

Characteristics

Characteristics

1. Large bearing capacity: can withstand large axial load.

2. Good rigidity: When bearing axial force, it is not easy to produce deformation.

3. Low friction coefficient: relatively smooth operation, reduce energy loss.

4. Strong impact resistance: able to withstand a certain degree of impact load.

Classification

Classification

1. Thrust cylindrical roller bearing: composed of cylindrical roller, cage assembly, shaft ring and seat ring.

2. Thrust tapered roller bearing: the roller is a conical shape, with better axial bearing capacity and tilt adjustment ability.

3. Thrust aligning roller bearing: the Angle of the roller can be automatically adjusted to adapt to the tilt of the shaft.

Basic Parameters

Basic Parameters

1. Inner diameter, outer diameter and width: determine the mounting size of the bearing.

2. Rated dynamic load and rated static load: indicates the load that the bearing can withstand under different working conditions.

3. Limit speed: the highest speed at which the bearing can operate safely.

The Working Principle

The Working Principle

The thrust roller bearing mainly reduces friction by rolling the roller between the raceway, transferring the axial load from the shaft to the bearing seat or other support structure. When the shaft is subjected to an axial force, the roller rolls on the raceway, absorbing and transmitting the axial force while maintaining the rotational accuracy of the shaft.

Application Fields

Application Fields

1. Heavy machinery: such as cranes, excavators, etc., bear huge axial loads.

2. Metallurgical equipment: rolling mill and other equipment to ensure the stable operation of the shaft.

3. Mining machinery: crusher, vibrating screen, etc., to provide reliable support in harsh working environment.

4. Power equipment: large generators, steam turbines, etc., to withstand axial thrust.

- Previous: Needle Roller Bearing

- Next: Tapered Roller Bearing

RELATED PRODUCTS