Angular contact ball bearing:7000B

Basic Parameters

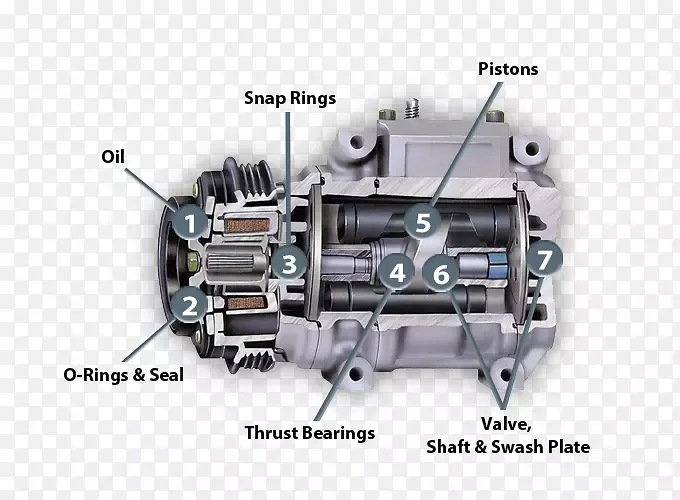

Basic ParametersIn the code "7000B", the "7" at the beginning indicates an angular contact ball bearing. This is the code for the bearing type. Angular contact ball bearings can bear radial and axial loads simultaneously. The contact angle is generally 15° - 40°. The part "000" represents the size series of the bearing. It is actually composed of a width series (here it is 0) and a diameter series (also 0 here). The size series is used to distinguish bearings with the same inner diameter but different outer diameters and widths. Different size series are suitable for different application scenarios such as installation spaces and load requirements. The final "B" is the internal structure code. In angular contact ball bearings, "B" indicates a contact angle of 40°. If it is "C", the contact angle is 15°; "AC" has a contact angle of 25°. These different contact angles make the bearing different in the ability to bear axial and radial loads. The larger the contact angle, the relatively stronger the axial bearing capacity. For example, on the main shaft of a precision machine tool, angular contact ball bearings with appropriate contact angles may be selected according to specific axial and radial load requirements. Bearings like 7000B with a contact angle of 40° may be used in cases where the axial load is relatively large.

Performance Advantages

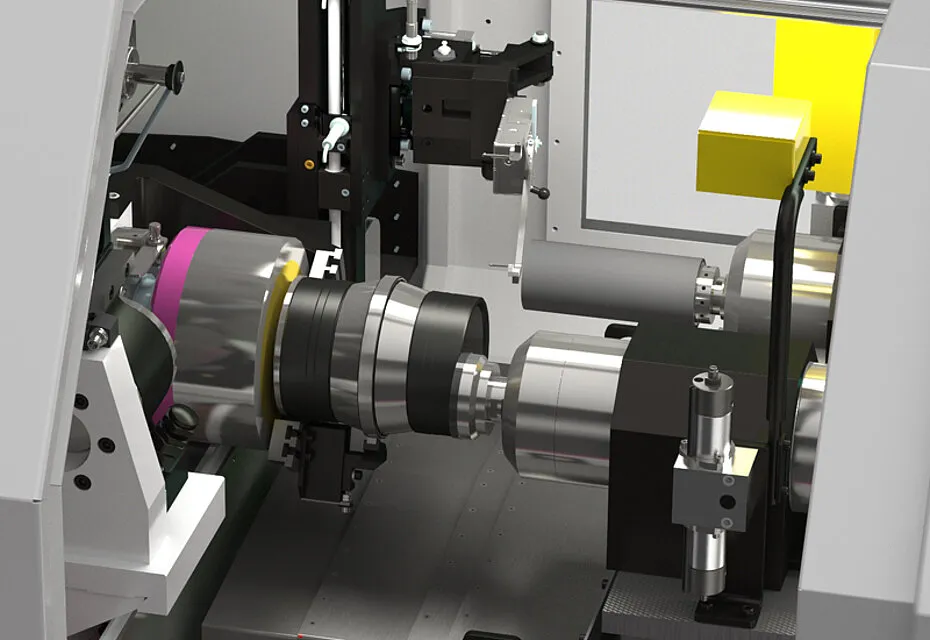

Performance AdvantagesHigh-precision operation: The manufacturing precision of bearing 7000B is very high and can meet the needs of various precision equipment. For example, in semiconductor manufacturing equipment, the precision requirements for chip processing are extremely high. Bearing 7000B can provide precise rotational movement to ensure that each component of the processing equipment works in precise coordination according to the design requirements, thereby improving the manufacturing quality of chips.

Good high-speed performance: Due to its low friction and high-precision design, bearing 7000B can adapt to high-speed operating conditions. In high-speed motors, it can easily reach tens of thousands of revolutions per minute, and still maintain stable performance under high-speed rotation, reducing vibration and noise. This is a very crucial performance advantage for some equipment with high speed requirements, such as the motors of drones and high-speed centrifuges.

Strong load-bearing capacity: Whether it is axial or radial load, bearing 7000B has excellent load-bearing capacity. In the joint parts of industrial robots, when robots perform various complex actions, they will generate loads in different directions. Bearing 7000B can effectively bear these loads, ensuring the flexible movement and precise control of robot joints, thereby improving the working efficiency and stability of robots.

Product Application

Product Application Product List

Product List| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight | ||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | (kg) |

| 7000 B | 66100 | 10 | 26 | 8 | 4650 | 2150 | 0.025 |

| 7001 B | 66101 | 12 | 28 | 8 | 4950 | 2500 | 0.027 |

| 7002 B | 66102 | 15 | 32 | 9 | 5550 | 3150 | 0.039 |

| 7003 B | 66103 | 17 | 35 | 10 | 6100 | 3750 | 0.051 |

| 7004 B | 66104 | 20 | 42 | 12 | 9350 | 5550 | 0.089 |

| 7005 B | 66105 | 25 | 47 | 12 | 10200 | 6700 | 0.103 |

| 7006 B | 66106 | 30 | 55 | 13 | 13100 | 9200 | 0.15 |

| 7007 B | 66107 | 35 | 62 | 14 | 15800 | 11400 | 0.207 |

| 7008 B | 66108 | 40 | 68 | 15 | 16800 | 13200 | 0.247 |

| 7009 B | 66109 | 45 | 75 | 16 | 20000 | 16000 | 0.31 |

| 7010 B | 66110 | 50 | 80 | 16 | 21200 | 18100 | 0.35 |

| 7011 B | 66111 | 55 | 90 | 18 | 27900 | 23700 | 0.47 |

| 7012 B | 66112 | 60 | 95 | 18 | 28600 | 25300 | 0.5 |

| 7013 B | 66113 | 65 | 100 | 18 | 30100 | 28300 | 0.54 |

| 7014 B | 66114 | 70 | 110 | 20 | 38300 | 35500 | 0.81 |

| 7015 B | 66115 | 75 | 115 | 20 | 39100 | 37600 | 0.86 |

| 7016 B | 66116 | 80 | 125 | 22 | 47800 | 45700 | 1.11 |

| 7017 B | 66117 | 85 | 130 | 22 | 48800 | 48400 | 1.25 |

| 7018 B | 66118 | 90 | 140 | 24 | 58400 | 57100 | 1.58 |

| 7019 B | 66119 | 95 | 145 | 24 | 59600 | 60500 | 1.67 |

| 7020 B | 66120 | 100 | 150 | 24 | 61200 | 63600 | 1.72 |

| 7021 B | 66121 | 105 | 160 | 26 | 71400 | 73800 | 2.16 |

| 7022 B | 66122 | 110 | 170 | 28 | 82300 | 83700 | 2.71 |

| 7024 B | 66124 | 120 | 180 | 28 | 86400 | 93000 | 2.94 |

| 7026 B | 66126 | 130 | 200 | 33 | 105000 | 113000 | 4.43 |

| 7028 B | 66128 | 140 | 210 | 33 | 107000 | 119000 | 4.7 |

| 7030 B | 66130 | 150 | 225 | 35 | 122000 | 138000 | 5.49 |

| 7032 B | 66132 | 160 | 240 | 38 | 139000 | 158000 | 6.67 |

| 7034 B | 66134 | 170 | 260 | 42 | 166000 | 193000 | 8.92 |

| 7036 B | 66136 | 180 | 280 | 46 | 190000 | 228000 | 11.28 |

| 7038 B | 66138 | 190 | 290 | 46 | 194000 | 241000 | 12.1 |

| 7040 B | 66140 | 200 | 310 | 51 | 218000 | 279000 | 15.59 |

| 7044 B | 66144 | 220 | 340 | 56 | 239000 | 318000 | 18.5 |

| 7048 B | 66148 | 240 | 360 | 56 | 244000 | 338000 | 19.7 |

| 7052 B | 66152 | 260 | 400 | 65 | 291000 | 431000 | 28.7 |

| 7056 B | 66156 | 280 | 420 | 65 | 297000 | 453000 | 30.4 |

| 7060 B | 66160 | 300 | 460 | 74 | 382000 | 613000 | 43.7 |

| 7064 B | 66164 | 320 | 480 | 74 | 391000 | 651000 | 46 |

| 7068 B | 66168 | 340 | 520 | 82 | 450000 | 777000 | 61.8 |

| 7072 B | 66172 | 360 | 540 | 82 | 461000 | 824000 | 64.6 |

| 7076 B | 66176 | 380 | 560 | 82 | 472000 | 870000 | 67.2 |

- Previous: Self aligning ball bearing:2204K

- Next: Angular contact ball bearing:7310

RELATED PRODUCTS