Double row angular contact ball bearing:3306 2RS

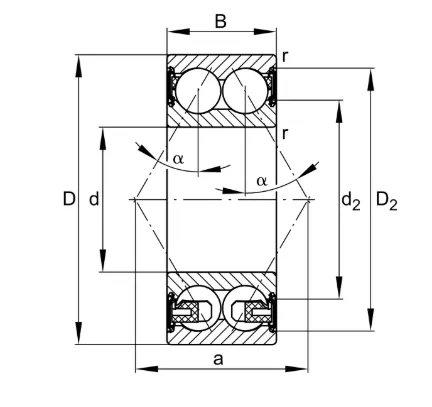

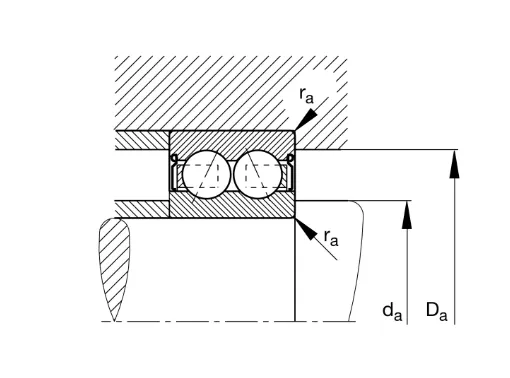

Basic Parameters

Basic Parameters WorkingStructural Features

WorkingStructural Features Product Application

Product ApplicationIndustrial machinery

Machine tool: Commonly used in the spindle part of machine tools. It can withstand the radial cutting force and axial thrust generated during the cutting process of machine tools, ensuring the rotational accuracy and stability of the spindle and thus ensuring the precision of machined parts. For example, it is widely used in CNC lathes, milling machines and other machine tools.

Reducer: In a reducer, the 3306-2RS bearing can be used to support the gear shaft and bear the radial load and axial load generated during gear transmission, enabling the reducer to transmit power smoothly, reducing vibration and noise and improving transmission efficiency.

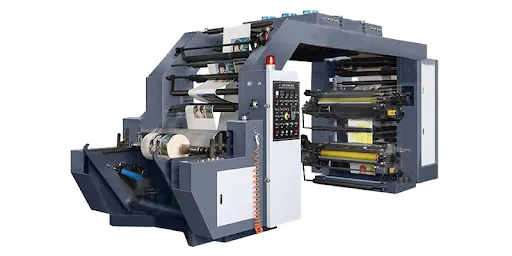

Printing machinery: In parts such as the roller shaft and paper feeding mechanism of a printing machine, bearings with high precision and load-bearing capacity are required to ensure the accurate conveyance of paper and the stable rotation of the roller during the printing process. The 3306-2RS bearing can meet these requirements and ensure printing quality.

Automotive industry

Wheel hub bearing: In the wheel hub parts of some light vehicles or minibuses, the 3306-2RS bearing can bear the radial load applied to the wheel hub by the road surface when the vehicle is driving and the axial load generated due to vehicle steering and braking. At the same time, it ensures the free rotation of the wheel hub, improving the driving safety and comfort of the vehicle.

Transmission: Used for shaft support in the transmission. It can bear the complex loads generated during shifting and power transmission of the transmission, including the radial force during gear meshing and the axial force caused by shifting operations, ensuring the normal operation of the transmission and reducing wear and failure.

Construction machinery

Excavator: In parts such as the slewing platform and bucket cylinder connection part of an excavator, the 3306-2RS bearing needs to bear large radial and axial loads to adapt to the complex stress conditions of the excavator during excavation and slewing operations, ensuring the flexible movement of each part and the stability of the whole machine.

Crane: The 3306-2RS bearing is also used in parts such as the boom telescoping mechanism and slewing mechanism of a crane. It can bear the huge load generated when the boom is telescoping and lifting heavy objects, as well as the radial and axial forces during the rotation of the slewing mechanism, ensuring the safe and reliable operation of the crane.

Motor field

Small and medium-sized motors: For some small and medium-sized motors with moderate power, the 3306-2RS bearing can be used to support the motor shaft and bear the weight of the rotor and the radial and axial forces caused by electromagnetic force during motor operation, ensuring the rotational accuracy and stability of the motor rotor, reducing vibration and noise and improving the efficiency and service life of the motor.

Other fields

Medical equipment: In some medical equipment such as the rotating parts of a CT machine and medical centrifuges, bearings with high precision, low noise and high reliability are required to ensure the normal operation of the equipment and detection accuracy. The 3306-2RS bearing has certain advantages in meeting these requirements.

Fitness equipment: For example, in parts such as the roller shaft of a treadmill and the pedal shaft of an exercise bike, the 3306-2RS bearing can bear the load applied by human movement, ensuring the smooth operation of the equipment and the comfortable experience of users.

-

printing machinery

-

treadmill

-

medical centrifuge

Product List

Product List| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight | ||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | (kg) |

| 3000 2RS | 3000 2RS | 10 | 26 | 12 | 5700 | 3250 | 0.022 |

| 3001 2RS | 3001 2RS | 12 | 28 | 12 | 6200 | 3750 | 0.025 |

| 3002 2RS | 3002 2RS | 15 | 32 | 13 | 8600 | 5400 | 0.036 |

| 3003 2RS | 3003 2RS | 17 | 35 | 14 | 9200 | 6200 | 0.042 |

| 3004 2RS | 3004 2RS | 20 | 42 | 16 | 14500 | 9600 | 0.08 |

| 3005 2RS | 3005 2RS | 25 | 47 | 16 | 15500 | 11100 | 0.1 |

| 3006 2RS | 3006 2RS | 30 | 55 | 19 | 20300 | 15600 | 0.16 |

| 3007 2RS | 3007 2RS | 35 | 62 | 20 | 24500 | 21400 | 0.2 |

| 3008 2RS | 3008 2RS | 40 | 68 | 21 | 25500 | 21700 | 0.25 |

| 3200 2RS | 3056200 2RS | 10 | 30 | 14 | 7410 | 4300 | 0.051 |

| 3201 2RS | 3056201 2RS | 12 | 32 | 15.9 | 10100 | 5600 | 0.058 |

| 3202 2RS | 3056202 2RS | 15 | 35 | 15.9 | 11200 | 6800 | 0.066 |

| 3203 2RS | 3056203 2RS | 17 | 40 | 17.5 | 14000 | 8650 | 0.096 |

| 3204 2RS | 3056204 2RS | 20 | 47 | 20.6 | 18600 | 12000 | 0.16 |

| 3205 2RS | 3056205 2RS | 25 | 52 | 20.6 | 20300 | 14000 | 0.18 |

| 3206 2RS | 3056206 2RS | 30 | 62 | 23.8 | 28100 | 20000 | 0.29 |

| 3207 2RS | 3056207 2RS | 35 | 72 | 27 | 37100 | 27500 | 0.44 |

| 3208 2RS | 3056208 2RS | 40 | 80 | 30.2 | 44900 | 33500 | 0.59 |

| 3209 2RS | 3056209 2RS | 45 | 85 | 30.2 | 47500 | 38000 | 0.63 |

| 3210 2RS | 3056210 2RS | 50 | 90 | 30.2 | 47500 | 39000 | 0.66 |

| 3211 2RS | 3056211 2RS | 55 | 100 | 33.3 | 57200 | 67000 | 1.05 |

| 3212 2RS | 3056212 2RS | 60 | 110 | 36.5 | 72100 | 85000 | 1.4 |

| 3213 2RS | 3056213 2RS | 65 | 120 | 38.1 | 78100 | 95000 | 1.75 |

| 3214 2RS | 3056214 2RS | 70 | 125 | 39.7 | 95000 | 83000 | 1.85 |

| 3215 2RS | 3056215 2RS | 75 | 130 | 41.3 | 95000 | 84000 | 2.1 |

| 3216 2RS | 3056216 2RS | 80 | 140 | 44.4 | 109000 | 102000 | 2.65 |

| 3217 2RS | 3056217 2RS | 85 | 150 | 49.2 | 129000 | 117000 | 3.4 |

| 3218 2RS | 3056218 2RS | 90 | 160 | 52.4 | 142000 | 142000 | 4.15 |

| 3220 2RS | 3056220 2RS | 100 | 180 | 60.3 | 187000 | 175000 | 5.5 |

| 3222 2RS | 3056222 2RS | 110 | 200 | 69.8 | 190000 | 180000 | 8.8 |

| 3302 2RS | 3056302 2RS | 15 | 42 | 19 | 15100 | 9150 | 0.13 |

| 3303 2RS | 3056303 2RS | 17 | 47 | 22.2 | 21200 | 12500 | 0.18 |

| 3304 2RS | 3056304 2RS | 20 | 52 | 22.2 | 22100 | 14300 | 0.22 |

| 3305 2RS | 3056305 2RS | 25 | 62 | 25.4 | 31200 | 20800 | 0.35 |

| 3306 2RS | 3056306 2RS | 30 | 72 | 30.2 | 41000 | 28500 | 0.53 |

| 3307 2RS | 3056307 2RS | 35 | 80 | 34.9 | 48800 | 34000 | 0.73 |

| 3308 2RS | 3056308 2RS | 40 | 90 | 36.5 | 56200 | 43000 | 0.95 |

| 3309 2RS | 3056309 2RS | 45 | 100 | 39.7 | 72100 | 73500 | 1.4 |

| 3310 2RS | 3056310 2RS | 50 | 110 | 44.4 | 88000 | 96500 | 1.95 |

| 3311 2RS | 3056311 2RS | 55 | 120 | 49.2 | 95200 | 108000 | 2.55 |

| 3312 2RS | 3056312 2RS | 60 | 130 | 54 | 112000 | 127000 | 3.25 |

| 3313 2RS | 3056313 2RS | 65 | 140 | 58.7 | 160000 | 126000 | 4 |

| 3314 2RS | 3056314 2RS | 70 | 150 | 63.5 | 161000 | 130000 | 4.9 |

| 3315 2RS | 3056315 2RS | 75 | 160 | 68.3 | 187000 | 160000 | 5.7 |

| 3316 2RS | 3056316 2RS | 80 | 170 | 68.3 | 198000 | 179000 | 6.95 |

| 3317 2RS | 3056317 2RS | 85 | 180 | 73 | 194000 | 185000 | 8.3 |

| 3318 2RS | 3056318 2RS | 90 | 190 | 73 | 220000 | 220000 | 9.25 |

| 3319 2RS | 3056319 2RS | 95 | 200 | 77.8 | 238000 | 315000 | 11 |

| 3320 2RS | 3056320 2RS | 100 | 215 | 82.6 | 255000 | 355000 | 12.5 |

| 3800 2RS | 3800 2RS | 10 | 19 | 7 | 2100 | 1400 | 0.008 |

| 3801 2RS | 3801 2RS | 12 | 21 | 7 | 2190 | 1550 | 0.008 |

| 3802 2RS | 3802 2RS | 15 | 24 | 7 | 2430 | 1960 | 0.009 |

| 3803 2RS | 3803 2RS | 17 | 26 | 7 | 2480 | 2080 | 0.015 |

| 3804 2RS | 3804 2RS | 20 | 32 | 10 | 5600 | 4850 | 0.02 |

| 3805 2RS | 3805 2RS | 25 | 37 | 10 | 6000 | 5600 | 0.025 |

| 3806 2RS | 3806 2RS | 30 | 42 | 10 | 6300 | 6100 | 0.03 |

| 3807 2RS | 3807 2RS | 35 | 47 | 10 | 6700 | 7000 | 0.035 |

| 3808 2RS | 3808 2RS | 40 | 52 | 10 | 7000 | 7800 | 0.04 |

| 3809 2RS | 3809 2RS | 45 | 58 | 10 | 7200 | 8300 | 0.053 |

| 3810 2RS | 3810 2RS | 50 | 65 | 12 | 8700 | 10400 | 0.07 |

| 3811 2RS | 3811 2RS | 55 | 72 | 13 | 12100 | 15700 | 0.09 |

| 3812 2RS | 3812 2RS | 60 | 78 | 14 | 14500 | 17500 | 0.14 |

| 3814 2RS | 3814 2RS | 70 | 90 | 15 | 19200 | 23800 | 0.19 |

| 3816 2RS | 3816 2RS | 80 | 100 | 15 | 19600 | 25500 | 0.23 |

| 3818 2RS | 3818 2RS | 90 | 115 | 19 | 27000 | 35500 | 0.457 |

| 3820 2RS | 3820 2RS | 100 | 125 | 19 | 28000 | 39000 | 0.5 |

RELATED PRODUCTS