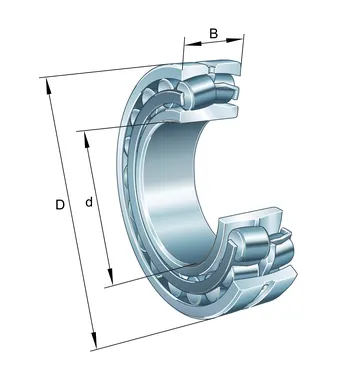

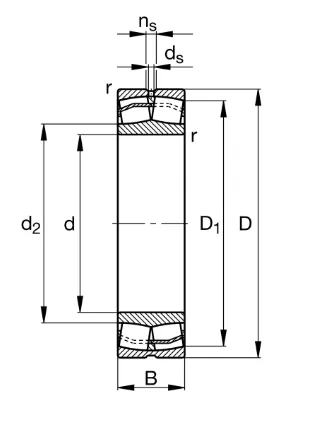

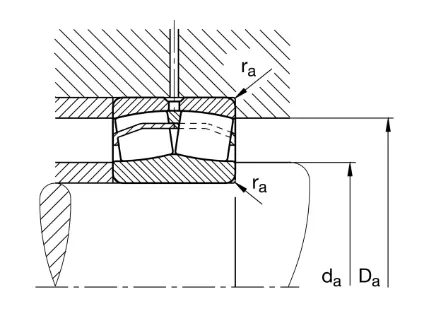

Basic Parameters

"22313" part: For self-aligning roller bearings, the composition of their basic codes has certain rules. The "2" at the front indicates the type of self-aligning roller bearing. Starting from the third digit, "2313" represents the size series and inner diameter size of the bearing. Among them, "23" represents the size series, which is the combined code of the width series and diameter series of the bearing. Here, the combination of the width series and diameter series determines the contour and load-carrying capacity and other related characteristics of the bearing. "13" multiplied by 5 equals 65mm, which means the inner diameter size of this bearing is 65mm.

"KMW33" part: The "K" in the bearing code has multiple meanings. Here, it may indicate a tapered hole (with a taper ratio of 1:12). This means that the inner hole of the bearing is conical in shape. This design facilitates the installation of the bearing on the shaft and the adjustment of the axial position. The "M" may represent a solid brass cage. The role of the cage is to evenly separate the rollers so that they can roll normally in the raceway and guide the rollers to move on the correct track, reducing collisions and friction between the rollers. The solid brass cage has good strength and wear resistance and can adapt to certain working environments and load conditions. "W33" is the additional code of the bearing. The "W" usually indicates that there are lubricating oil grooves and three lubricating oil holes on the outer ring of the bearing. The design of these oil grooves and oil holes is to facilitate lubrication so that the lubricant can better enter the interior of the bearing and form a good lubricating film between the rollers and the raceway, thereby reducing friction and wear and improving the service life of the bearing.

-

22313 KMW33

-

22313 KMW33

-

22313 KMW33

Bearing types and characteristics

-

Bearing 22313KMW33 belongs to the category of spherical roller bearings. The greatest advantage of this type of bearing lies in its excellent self-aligning performance. In the actual equipment operating environment, due to factors such as installation errors, shaft deflection deformation, or vibrations generated during equipment operation, there is a high likelihood of a certain degree of angular deviation between the shaft and the housing bore. And our spherical roller bearings can automatically adapt to this deviation. Through the special structural design between the rollers and the raceway, the bearing can flexibly adjust its own angle, thereby avoiding the local stress concentration phenomenon caused by misalignment between the shaft and the housing. This automatic self-aligning function is like an intelligent balancer, which can effectively reduce bearing wear and extend its service life. It is especially suitable for equipment that has high installation precision requirements but is difficult to completely avoid errors during the actual installation process.

-

It also has the ability to simultaneously withstand relatively large radial loads and axial loads. In equipment such as a paper machine dryer cylinder, the radial load mainly comes from the weight of the dryer cylinder itself, the tension of the paper, and the centrifugal force during rotation, etc.; the axial load may be generated due to factors such as the transmission structure of the equipment and the paper misalignment correction device. Bearing 22313KMW33 can work stably in these complex load environments, just like a strong guard, firmly supporting the normal operation of the dryer cylinder.

Performance highlights

Performance highlightsStrong carrying capacity

- This bearing's internal structure is carefully designed. The size, quantity, and distribution pattern of the rollers are optimized to enable it to bear a relatively high load. In heavy industrial equipment, such as the drying cylinders of paper machines, due to the large volume of the drying cylinders and the need for continuous operation, the load they bear is extremely heavy. The high carrying capacity of bearing 22313KMW33 can ensure that the drying cylinder can still operate stably under full-load working conditions without excessive extrusion and deformation between the rollers and raceways due to excessive load, thus ensuring the reliability and production efficiency of the equipment.

Excellent wear resistance

- During the manufacturing process, we use high-quality bearing steel materials. This material itself has good hardness and toughness. Moreover, in the processing technology, the contact surface between the rollers and raceways is finely ground and heat-treated to form a hard and smooth surface. This surface is like a tough armor. During the long-term operation of the bearing, it can effectively resist the wear of the bearing caused by paper fibers, dust particles, and other impurities. Even in harsh working environments such as the humid and dusty environment of a paper mill, it can still maintain a good working state, reducing the frequency of maintenance and replacement and saving costs for you.

High operational stability

- Thanks to advanced manufacturing technology and strict quality control, bearing 22313KMW33 can maintain a low level of vibration and noise during high-speed rotation. During the operation of the drying cylinder of a paper machine, the stable operating state can not only improve the production quality of paper and avoid problems such as uneven paper thickness caused by vibration but also create a relatively quiet and comfortable working environment for operators. At the same time, lower vibration also helps to reduce the impact on other parts of the equipment and extend the service life of the entire equipment.

Application scenarios

Application scenariosPaper machine dryer cylinder field

-

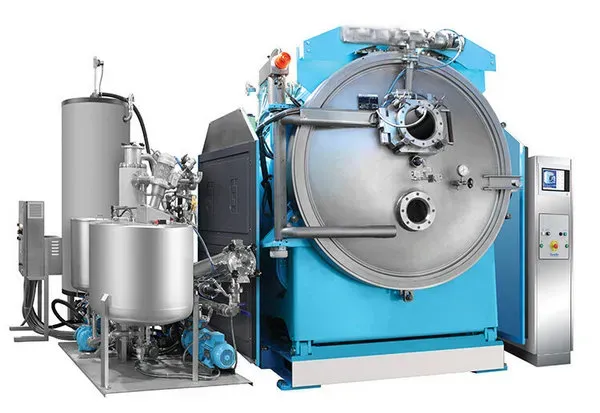

Paper machine dryer cylinder

-

Roller of printing and dyeing machine

-

Stretching roller of plastic film production equipment

-

In the dryer cylinder part of the paper machine, the bearing 22313KMW33 plays a crucial role. When in operation, the dryer cylinder needs to continuously rotate in a high-temperature and high-humidity environment while bearing various complex loads from the paper tension, its own gravity, and the transmission system. Our bearing can ensure the rotational accuracy of the dryer cylinder with its self-aligning performance, high load-carrying capacity, and stable operating characteristics, thereby guaranteeing the quality of the paper during the drying process, such as the flatness and uniform drying of the paper.

-

In addition to paper machine dryer cylinders, it is also suitable for other similar industrial equipment that requires high-precision rotational support, such as the rollers of printing and dyeing machines and the stretching rollers of plastic film production equipment. These equipment all have similar load and precision requirements during operation, and the bearing 22313KMW33 can meet their needs.

Maintenance tips

Maintenance tipsLubrication and maintenance

- Good lubrication is the key to ensuring the performance of bearing 22313KMW33. According to the working environment and operation requirements of the equipment, we recommend that you choose a suitable lubricant. For high-temperature environments such as paper machine dryer cylinders, high-temperature-resistant grease may be needed. Regularly check and replenish the lubricant to ensure that a good lubrication state is always maintained between the rollers and raceways. This is just like regularly adding lubricating oil to the "joints" of the bearing to enable it to operate flexibly.

Cleaning and protection

- Due to the relatively complex environment of the paper mill workshop with more impurities such as dust and paper fibers, special attention should be paid to keeping the bearing clean. Appropriate protective devices such as sealing covers can be installed on the equipment to prevent impurities from entering the bearing interior. At the same time, regularly clean the dust and debris around the bearing to avoid excessive accumulation and entry into the bearing, affecting its normal operation.

Regular inspection

- Regular inspection of the operating state of the bearing is essential. You can judge its working state by observing indicators such as the temperature, vibration, and noise of the bearing. If abnormal temperature rise, increased vibration, or increased noise is found, it may mean that there is a problem with the bearing. It is necessary to stop the machine for inspection in time, find out the problem and carry out corresponding repair or replacement.

Product List

| Bearing No. |

Dimensions (mm) |

Basic Load Rating (N) |

Weight |

| ISO |

GOST |

d |

D |

B |

Dyn. C |

Stat. C0 |

(kg) |

| 22205 KMW33 |

113505 H |

25 |

52 |

18 |

35800 |

36800 |

0.17 |

| 22206 KMW33 |

113506 H |

30 |

62 |

20 |

50500 |

55000 |

0.269 |

| 22207 KMW33 |

113507 H |

35 |

72 |

23 |

66500 |

76000 |

0.406 |

| 22208 KMW33 |

113508 H |

40 |

80 |

23 |

78500 |

90800 |

0.506 |

| 22209 KMW33 |

113509 H |

45 |

85 |

23 |

82000 |

97500 |

0.571 |

| 22210 KMW33 |

113510 H |

50 |

90 |

23 |

84500 |

105000 |

0.612 |

| 22211 KMW33 |

113511 H |

55 |

100 |

25 |

102000 |

125000 |

0.84 |

| 22212 KMW33 |

113512 H |

60 |

110 |

28 |

122000 |

155000 |

1.12 |

| 22213 KMW33 |

113513 H |

65 |

120 |

31 |

150000 |

195000 |

1.526 |

| 22214 KMW33 |

113514 H |

70 |

125 |

31 |

158000 |

205000 |

1.591 |

| 22215 KMW33 |

113515 H |

75 |

130 |

31 |

162000 |

215000 |

1.697 |

| 22216 KMW33 |

113516 H |

80 |

140 |

33 |

175000 |

238000 |

2.05 |

| 22217 KMW33 |

113517 H |

85 |

150 |

36 |

210000 |

278000 |

2.647 |

| 22218 KMW33 |

113518 H |

90 |

160 |

40 |

240000 |

322000 |

3.364 |

| 22219 KMW33 |

113519 H |

95 |

170 |

43 |

278000 |

380000 |

3.947 |

| 22220 KMW33 |

113520 H |

100 |

180 |

46 |

310000 |

425000 |

4.888 |

| 22222 KMW33 |

113522 H |

110 |

200 |

53 |

405000 |

575000 |

7 |

| 22224 KMW33 |

113524 H |

120 |

215 |

58 |

470000 |

678000 |

8.48 |

| 22226 KMW33 |

113526 H |

130 |

230 |

64 |

550000 |

810000 |

10.89 |

| 22228 KMW33 |

113528 H |

140 |

250 |

68 |

628000 |

930000 |

13.68 |

| 22230 KMW33 |

113530 H |

150 |

270 |

73 |

738000 |

1100000 |

17.36 |

| 22232 KMW33 |

113532 H |

160 |

290 |

80 |

825000 |

1250000 |

21.92 |

| 22234 KMW33 |

113534 H |

170 |

310 |

86 |

720000 |

1300000 |

27 |

| 22236 KMW33 |

113536 H |

180 |

320 |

86 |

735000 |

1370000 |

27 |

| 22238 KMW33 |

113538 H |

190 |

340 |

92 |

818000 |

1510000 |

36.8 |

| 22240 KMW33 |

113540 H |

200 |

360 |

98 |

920000 |

1740000 |

42.5 |

| 22244 KMW33 |

113544 H |

220 |

400 |

108 |

1170000 |

2220000 |

58 |

| 22308 KMW33 |

113608 H |

40 |

90 |

33 |

120000 |

138000 |

1 |

| 22309 KMW33 |

113609 H |

45 |

100 |

36 |

142000 |

170000 |

1.368 |

| 22310 KMW33 |

113610 H |

50 |

110 |

40 |

175000 |

210000 |

1.82 |

| 22311 KMW33 |

113611 H |

55 |

120 |

43 |

208000 |

250000 |

2.26 |

| 22312 KMW33 |

113612 H |

60 |

130 |

46 |

238000 |

285000 |

2.772 |

| 22313 KMW33 |

113613 H |

65 |

140 |

48 |

260000 |

315000 |

3.42 |

| 22314 KMW33 |

113614 H |

70 |

150 |

51 |

292000 |

362000 |

4.204 |

| 22315 KMW33 |

113615 H |

75 |

160 |

55 |

342000 |

438000 |

5.052 |

| 22316 KMW33 |

113616 H |

80 |

170 |

58 |

385000 |

498000 |

6.12 |

| 22317 KMW33 |

113617 H |

85 |

180 |

60 |

420000 |

540000 |

6.78 |

| 22318 KMW33 |

113618 H |

90 |

190 |

64 |

475000 |

622000 |

8.388 |

| 22319 KMW33 |

113619 H |

95 |

200 |

67 |

520000 |

688000 |

9.872 |

| 22320 KMW33 |

113620 H |

100 |

215 |

73 |

608000 |

815000 |

12.62 |

| 22322 KMW33 |

113622 H |

110 |

240 |

80 |

695000 |

935000 |

17.27 |

| 22324 KMW33 |

113624 H |

120 |

260 |

86 |

822000 |

1120000 |

21 |

| 22326 KMW33 |

113626 H |

130 |

280 |

93 |

942000 |

1300000 |

27 |

| 22328 KMW33 |

113628 H |

140 |

300 |

102 |

1110000 |

1570000 |

33.8 |

| 22330 KMW33 |

113630 H |

150 |

320 |

108 |

1020000 |

1740000 |

40.6 |

| 22332 KMW33 |

113632 H |

160 |

340 |

114 |

1040000 |

1770000 |

48 |

| 22334 KMW33 |

113634 H |

170 |

360 |

120 |

1150000 |

2060000 |

58.5 |

| 22336 KMW33 |

113636 H |

180 |

380 |

126 |

1260000 |

2270000 |

68.5 |

| 22338 KMW33 |

113638 H |

190 |

400 |

132 |

1390000 |

2530000 |

79.4 |

| 22340 KMW33 |

113640 H |

200 |

420 |

138 |

1490000 |

2720000 |

91.4 |

| 22344 KMW33 |

113644 H |

220 |

460 |

145 |

1690000 |

3200000 |

115 |

Basic Parameters

Basic Parameters

Application scenarios

Application scenarios

Maintenance tips

Maintenance tips Product List

Product List