Spherical roller bearing: 22210 CW33

Basic Parameters

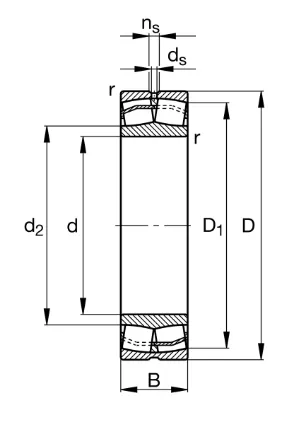

Basic ParametersThe part "'22210'. The '2' at the beginning represents that the bearing type is a spherical roller bearing. This is a kind of bearing that can automatically compensate for the angular deviation between the shaft and the housing hole. It is mainly used to bear radial loads and can also bear a certain amount of axial load.

From the third digit, '2210' is used to represent the size series and inner diameter size. Among them, '22' is the size series code, which is a combination of width series and diameter series. Different size series determine the dimensional proportions and load-carrying capacity and other characteristics of the bearing. '10' multiplied by 5 gives an inner diameter size of 50mm, which is a key parameter for determining the size of the bearing inner hole and is used for fitting with shafts of corresponding sizes.

The part "'CW33'. The 'C' in the bearing code has multiple meanings. Here, it may represent certain characteristics of the internal structure design. For spherical roller bearings, it may involve the shape of the rollers, the structure of the cage, or the configuration of other internal components. These internal structural characteristics will affect the performance of the bearing, such as load-carrying capacity and frictional torque.

'W33' is the additional code of the bearing. 'W' usually indicates that there are lubricating oil grooves and three lubricating oil holes on the outer ring of the bearing. This design helps better lubrication during the operation of the bearing. The lubricating oil groove can store lubricant, and the lubricating oil hole facilitates the entry of lubricant between the rollers and raceways inside the bearing, thereby effectively reducing friction and wear, improving the service life of the bearing. And in some working environments that require good lubrication conditions, such as high-speed rotation or heavy-load equipment, this design is particularly important.

-

22210 CW33

-

22210 CW33

-

22210 CW33

Bearing types and characteristics

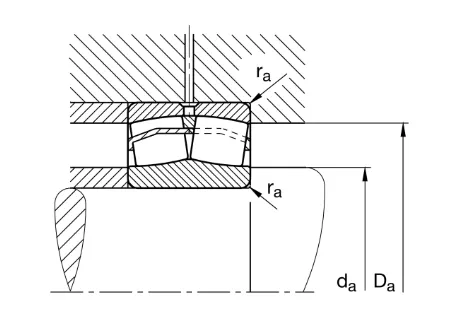

Bearing types and characteristicsSpherical roller bearing: 22210 CW33 belongs to spherical roller bearings. It has excellent self-aligning performance. When the shaft in the equipment has an angular deviation with the housing hole due to installation errors, deflection deformation or vibration and other reasons, this bearing can automatically adapt to this deviation, avoid local stress concentration, reduce bearing wear and extend service life. At the same time, it can bear a large radial load and a certain axial load at the same time, and is suitable for working conditions with complex loads.

Performance highlights

Performance highlightsGood load-carrying capacity: By optimizing the internal structure, such as the size, quantity, and distribution of rollers, the bearing has a high load-carrying capacity. It can stably support the operation of heavy equipment such as paper machine dryer cylinders and bear various loads such as the self-weight of the dryer cylinder and paper tension.

Reliable wear resistance: Made of high-quality bearing steel, the contact surface between the roller and raceway is finely ground and heat-treated to form a hard and smooth surface. In harsh working environments such as the humid and dusty environment of a paper mill, it can effectively resist impurity wear and reduce the frequency of maintenance and replacement.

Stable operation: Advanced manufacturing technology and strict quality control ensure that the bearing has low vibration and noise levels when rotating at high speed. In equipment such as paper machine dryer cylinders, it can improve product quality, avoid paper quality problems caused by vibration, and at the same time create a quiet working environment for operators and help extend the service life of other components of the equipment.

Applicable Scene

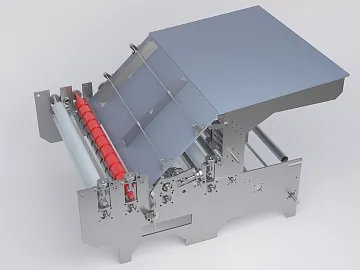

Applicable Scene

Maintenance Tips

Product List

Product List| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight | ||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | (kg) |

| 22205 CW33 | 53505 H | 25 | 52 | 18 | 35800 | 36800 | 0.174 |

| 22206 CW33 | 53506 H | 30 | 62 | 20 | 50500 | 55000 | 0.27 |

| 22207 CW33 | 53507 H | 35 | 72 | 23 | 66500 | 76000 | 0.41 |

| 22208 CW33 | 53508 H | 40 | 80 | 23 | 78500 | 90800 | 0.52 |

| 22209 CW33 | 53509 H | 45 | 85 | 23 | 82000 | 97500 | 0.564 |

| 22210 CW33 | 53510 H | 50 | 90 | 23 | 84500 | 105000 | 0.618 |

| 22211 CW33 | 53511 H | 55 | 100 | 25 | 102000 | 125000 | 0.84 |

| 22212 CW33 | 53512 H | 60 | 110 | 28 | 122000 | 155000 | 1.114 |

| 22213 CW33 | 53513 H | 65 | 120 | 31 | 150000 | 195000 | 1.55 |

| 22214 CW33 | 53514 H | 70 | 125 | 31 | 158000 | 205000 | 1.584 |

| 22215 CW33 | 53515 H | 75 | 130 | 31 | 162000 | 215000 | 1.61 |

| 22216 CW33 | 53516 H | 80 | 140 | 33 | 175000 | 238000 | 2.058 |

| 22217 CW33 | 53517 H | 85 | 150 | 36 | 210000 | 278000 | 2.47 |

| 22218 CW33 | 53518 H | 90 | 160 | 40 | 240000 | 322000 | 3.344 |

| 22219 CW33 | 53519 H | 95 | 170 | 43 | 278000 | 380000 | 4 |

| 22220 CW33 | 53520 H | 100 | 180 | 46 | 310000 | 425000 | 4.894 |

| 22222 CW33 | 53522 H | 110 | 200 | 53 | 405000 | 575000 | 7.1 |

| 22224 CW33 | 53524 H | 120 | 215 | 58 | 470000 | 678000 | 8.752 |

| 22226 CW33 | 53526 H | 130 | 230 | 64 | 550000 | 810000 | 10.4 |

| 22228 CW33 | 53528 H | 140 | 250 | 68 | 628000 | 930000 | 13.99 |

| 22230 CW33 | 53530 H | 150 | 270 | 73 | 738000 | 1100000 | 17.27 |

| 22308 CW33 | 53608 H | 40 | 90 | 33 | 120000 | 138000 | 0.994 |

| 22309 CW33 | 53609 H | 45 | 100 | 36 | 142000 | 170000 | 1.34 |

| 22310 CW33 | 53610 H | 50 | 110 | 40 | 175000 | 210000 | 1.78 |

| 22311 CW33 | 53611 H | 55 | 120 | 43 | 208000 | 250000 | 2.25 |

| 22312 CW33 | 53612 H | 60 | 130 | 46 | 238000 | 285000 | 2.788 |

| 22313 CW33 | 53613 H | 65 | 140 | 48 | 260000 | 315000 | 3.52 |

| 22314 CW33 | 53614 H | 70 | 150 | 51 | 292000 | 362000 | 4.206 |

| 22315 CW33 | 53615 H | 75 | 160 | 55 | 342000 | 438000 | 5.108 |

| 22316 CW33 | 53616 H | 80 | 170 | 58 | 385000 | 498000 | 6.09 |

| 22317 CW33 | 53617 H | 85 | 180 | 60 | 420000 | 540000 | 6.84 |

| 22318 CW33 | 53618 H | 90 | 190 | 64 | 475000 | 622000 | 8.392 |

| 22319 CW33 | 53619 H | 95 | 200 | 67 | 520000 | 688000 | 9.964 |

| 22320 CW33 | 53620 H | 100 | 215 | 73 | 608000 | 815000 | 12.36 |

RELATED PRODUCTS