Spherical roller bearing:23068 MW33

Basic Parameters

Basic Parameters

Bearing types and characteristics

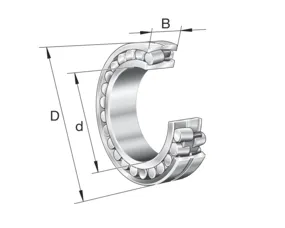

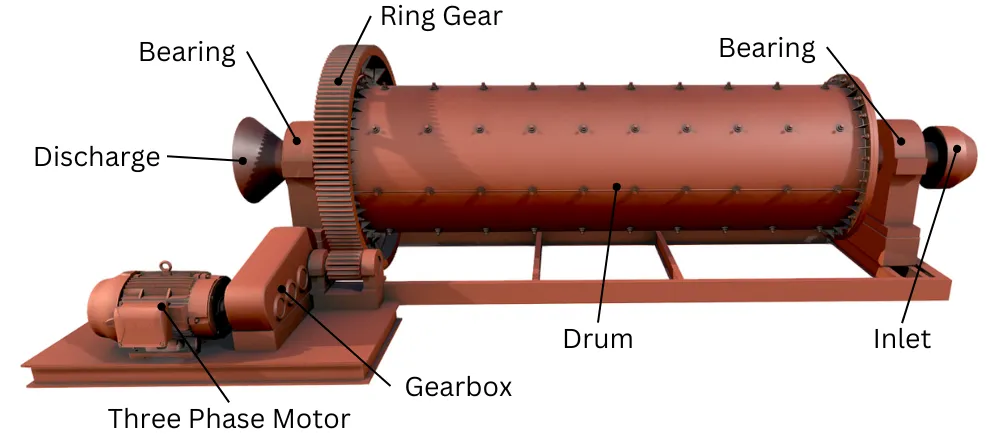

Bearing types and characteristicsSpherical roller bearing: 23068 MW33 belongs to spherical roller bearings. It has excellent self-aligning performance. When there is an angular deviation between the shaft and the housing hole, it can automatically adapt, avoid local stress concentration, reduce wear and prolong service life. At the same time, it can bear a large radial load and a certain axial load, and is suitable for working conditions with complex loads.

Performance highlights

Performance highlights Applicable scene

Applicable scene

Maintenance Tips

Lubrication aspect: Select suitable lubricants according to the working environment and operation requirements of the equipment. For high-temperature environments, high-temperature-resistant grease is required. And regularly check and replenish lubricants to maintain a good lubrication state between rollers and raceways.

Cleaning and protection: Since the application scenarios are often complex environments, attention should be paid to keeping the bearings clean. Protective devices such as sealing covers can be installed to prevent dust and impurities from entering the interior of the bearings. Also, regularly clean up debris around the bearings.

Product List

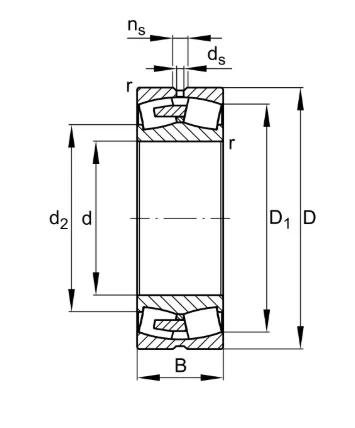

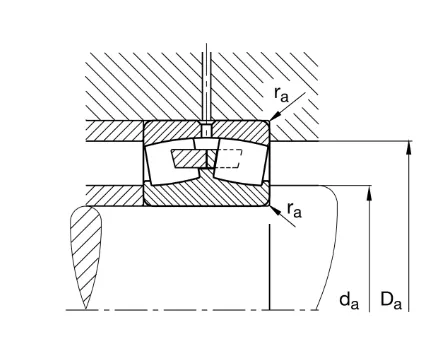

Product List| Bearing No. | Dimensions (mm) | Basic Load Rating (N) | Weight | ||||

| ISO | GOST | d | D | B | Dyn. C | Stat. C0 | (kg) |

| 22205 MW33 | 3505 H | 25 | 52 | 18 | 35800 | 36800 | 0.178 |

| 22206 MW33 | 3506 H | 30 | 62 | 20 | 50500 | 55000 | 0.272 |

| 22207 MW33 | 3507 H | 35 | 72 | 23 | 66500 | 76000 | 0.43 |

| 22208 MW33 | 3508 H | 40 | 80 | 23 | 78500 | 90800 | 0.54 |

| 22209 MW33 | 3509 H | 45 | 85 | 23 | 82000 | 97500 | 0.58 |

| 22210 MW33 | 3510 H | 50 | 90 | 23 | 84500 | 105000 | 0.62 |

| 22211 MW33 | 3511 H | 55 | 100 | 25 | 102000 | 125000 | 0.852 |

| 22212 MW33 | 3512 H | 60 | 110 | 28 | 122000 | 155000 | 1.126 |

| 22213 MW33 | 3513 H | 65 | 120 | 31 | 150000 | 195000 | 1.56 |

| 22214 MW33 | 3514 H | 70 | 125 | 31 | 158000 | 205000 | 1.602 |

| 22215 MW33 | 3515 H | 75 | 130 | 31 | 162000 | 215000 | 1.704 |

| 22216 MW33 | 3516 H | 80 | 140 | 33 | 175000 | 238000 | 2.12 |

| 22217 MW33 | 3517 H | 85 | 150 | 36 | 210000 | 278000 | 2.662 |

| 22218 MW33 | 3518 H | 90 | 160 | 40 | 240000 | 322000 | 3.482 |

| 22219 MW33 | 3519 H | 95 | 170 | 43 | 278000 | 380000 | 4.1 |

| 22220 MW33 | 3520 H | 100 | 180 | 46 | 310000 | 425000 | 4.988 |

| 22222 MW33 | 3522 H | 110 | 200 | 53 | 405000 | 575000 | 7.136 |

| 22224 MW33 | 3524 H | 120 | 215 | 58 | 470000 | 678000 | 8.842 |

| 22226 MW33 | 3526 H | 130 | 230 | 64 | 550000 | 810000 | 11 |

| 22228 MW33 | 3528 H | 140 | 250 | 68 | 628000 | 930000 | 14 |

| 22230 MW33 | 3530 H | 150 | 270 | 73 | 738000 | 1100000 | 17.72 |

| 22232 MW33 | 3532 H | 160 | 290 | 80 | 825000 | 1250000 | 22 |

| 22234 MW33 | 3534 H | 170 | 310 | 86 | 720000 | 1300000 | 28 |

| 22236 MW33 | 3536 H | 180 | 320 | 86 | 735000 | 1370000 | 28 |

| 22238 MW33 | 3538 H | 190 | 340 | 92 | 818000 | 1510000 | 37 |

| 22240 MW33 | 3540 H | 200 | 360 | 98 | 920000 | 1740000 | 43 |

| 22244 MW33 | 3544 H | 220 | 400 | 108 | 1170000 | 2220000 | 59 |

| 22248 MW33 | 3548 H | 240 | 440 | 120 | 1900000 | 2980000 | 83 |

| 22252 MW33 | 3552 H | 260 | 480 | 130 | 2270000 | 3470000 | 103 |

| 22256 MW33 | 3556 H | 280 | 500 | 130 | 1690000 | 3380000 | 109 |

| 22308 MW33 | 3608 H | 40 | 90 | 33 | 120000 | 138000 | 1.01 |

| 22309 MW33 | 3609 H | 45 | 100 | 36 | 142000 | 170000 | 1.374 |

| 22310 MW33 | 3610 H | 50 | 110 | 40 | 175000 | 210000 | 1.85 |

| 22311 MW33 | 3611 H | 55 | 120 | 43 | 208000 | 250000 | 2.31 |

| 22312 MW33 | 3612 H | 60 | 130 | 46 | 238000 | 285000 | 2.86 |

| 22313 MW33 | 3613 H | 65 | 140 | 48 | 260000 | 315000 | 3.468 |

| 22314 MW33 | 3614 H | 70 | 150 | 51 | 292000 | 362000 | 4.28 |

| 22315 MW33 | 3615 H | 75 | 160 | 55 | 342000 | 438000 | 5.22 |

| 22316 MW33 | 3616 H | 80 | 170 | 58 | 385000 | 498000 | 6.13 |

| 22317 MW33 | 3617 H | 85 | 180 | 60 | 420000 | 540000 | 6.942 |

| 22318 MW33 | 3618 H | 90 | 190 | 64 | 475000 | 622000 | 8.552 |

| 22319 MW33 | 3619 H | 95 | 200 | 67 | 520000 | 688000 | 9.998 |

| 22320 MW33 | 3620 H | 100 | 215 | 73 | 608000 | 815000 | 12.71 |

| 22322 MW33 | 3622 H | 110 | 240 | 80 | 695000 | 935000 | 17.34 |

| 22324 MW33 | 3624 H | 120 | 260 | 86 | 822000 | 1120000 | 22 |

| 22326 MW33 | 3626 H | 130 | 280 | 93 | 942000 | 1300000 | 28.5 |

| 22328 MW33 | 3628 H | 140 | 300 | 102 | 1110000 | 1570000 | 34.5 |

| 22330 MW33 | 3630 H | 150 | 320 | 108 | 1020000 | 1740000 | 41.5 |

| 22332 MW33 | 3632 H | 160 | 340 | 114 | 1040000 | 1770000 | 50 |

| 22334 MW33 | 3634 H | 170 | 360 | 120 | 1150000 | 2060000 | 59 |

| 22336 MW33 | 3636 H | 180 | 380 | 126 | 1260000 | 2270000 | 70 |

| 22338 MW33 | 3638 H | 190 | 400 | 132 | 1390000 | 2530000 | 80 |

| 22340 MW33 | 3640 H | 200 | 420 | 138 | 1490000 | 2720000 | 93 |

| 22344 MW33 | 3644 H | 220 | 460 | 145 | 1690000 | 3200000 | 117 |

| 22352 MW33 | 3652 H | 260 | 540 | 165 | 2200000 | 4190000 | 187 |

| 22356 MW33 | 3656 H | 280 | 580 | 175 | 2420000 | 4650000 | 229 |

| 22380 MW33 | 3680 H | 400 | 820 | 243 | 4530000 | 9290000 | 653 |

| 23030 MW33 | 3003130 H | 150 | 225 | 56 | 438000 | 762000 | 7.818 |

| 23032 MW33 | 3003132 H | 160 | 240 | 60 | 500000 | 875000 | 9.52 |

| 23034 MW33 | 3003134 H | 170 | 260 | 67 | 608000 | 1080000 | 13.29 |

| 23036 MW33 | 3003136 H | 180 | 280 | 74 | 710000 | 1260000 | 17.36 |

| 23038 MW33 | 3003138 H | 190 | 290 | 75 | 745000 | 1350000 | 17.76 |

| 23040 MW33 | 3003140 H | 200 | 310 | 82 | 580000 | 1310000 | 23.59 |

| 23044 MW33 | 3003144 H | 220 | 340 | 90 | 633000 | 171000 | 30.5 |

| 23048 MW33 | 3003148 H | 240 | 360 | 92 | 792000 | 2060000 | 33 |

| 23052 MW33 | 3003152 H | 260 | 400 | 104 | 1000000 | 2450000 | 47 |

| 23056 MW33 | 3003156 H | 280 | 420 | 106 | 1080000 | 2680000 | 51 |

| 23060 MW33 | 3003160 H | 300 | 460 | 118 | 1860000 | 3690000 | 71 |

| 23064 MW33 | 3003164 H | 320 | 480 | 121 | 1380000 | 3260000 | 77 |

| 23068 MW33 | 3003168 H | 340 | 520 | 133 | 1580000 | 3810000 | 109 |

| 23120 MW33 | 3003720 H | 100 | 165 | 52 | 320000 | 505000 | 4.48 |

| 23122 MW33 | 3003722 H | 110 | 180 | 56 | 375000 | 595000 | 5.471 |

| 23220 MW33 | 3003220 H | 100 | 180 | 60.3 | 415000 | 618000 | 6.624 |

| 23222 MW33 | 3003222 H | 110 | 200 | 69.8 | 515000 | 785000 | 9.588 |

| 23244 MW33 | 3003244 H | 220 | 400 | 144 | 2070000 | 3620000 | 79 |

| 23264 MW33 | 3003264 H | 320 | 580 | 208 | 3760000 | 6570000 | 241 |

RELATED PRODUCTS